Beryllium-aluminum-zirconium-series multi-element alloy and preparation method thereof

A multi-alloy, zirconium-based technology, applied in the field of non-ferrous metal alloys and beryllium aluminum alloy manufacturing, can solve the problems of high cost, complicated process, limited application of beryllium aluminum alloy, etc., and achieve the effect of low cost, simple process and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

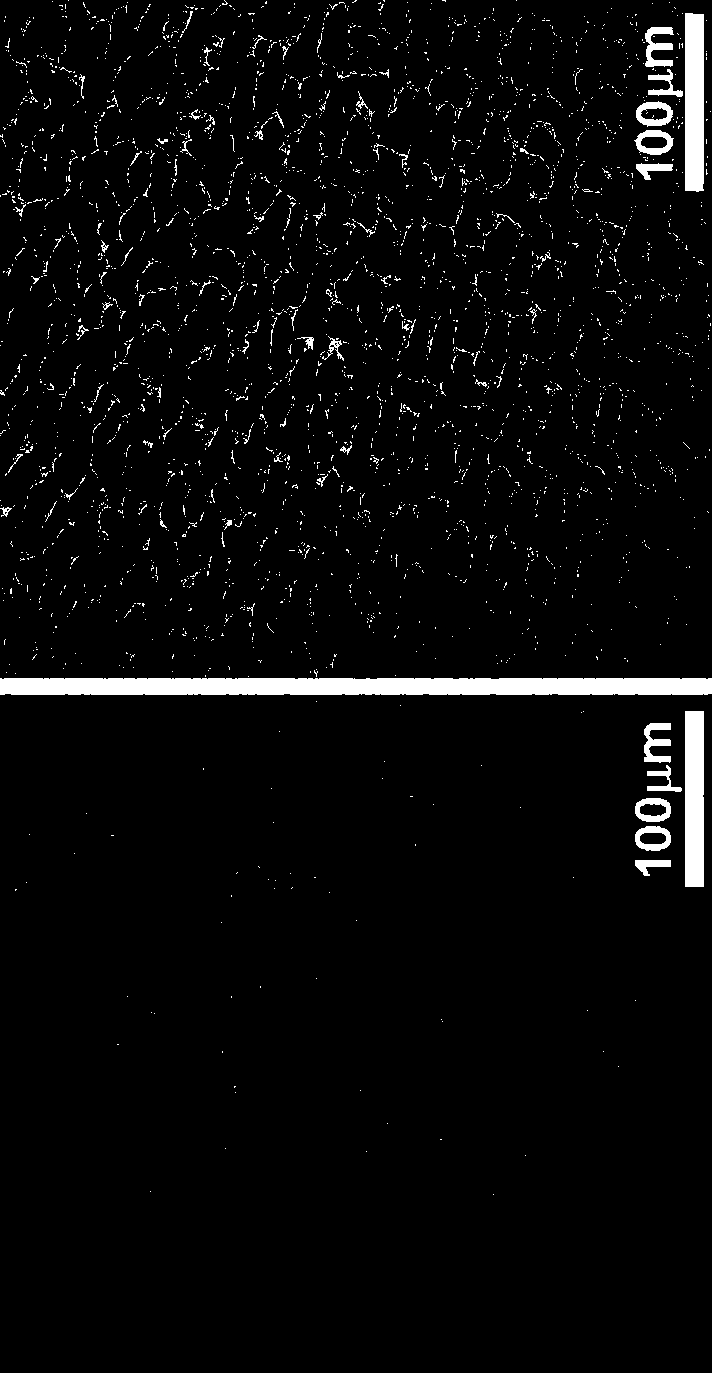

Image

Examples

Embodiment 1

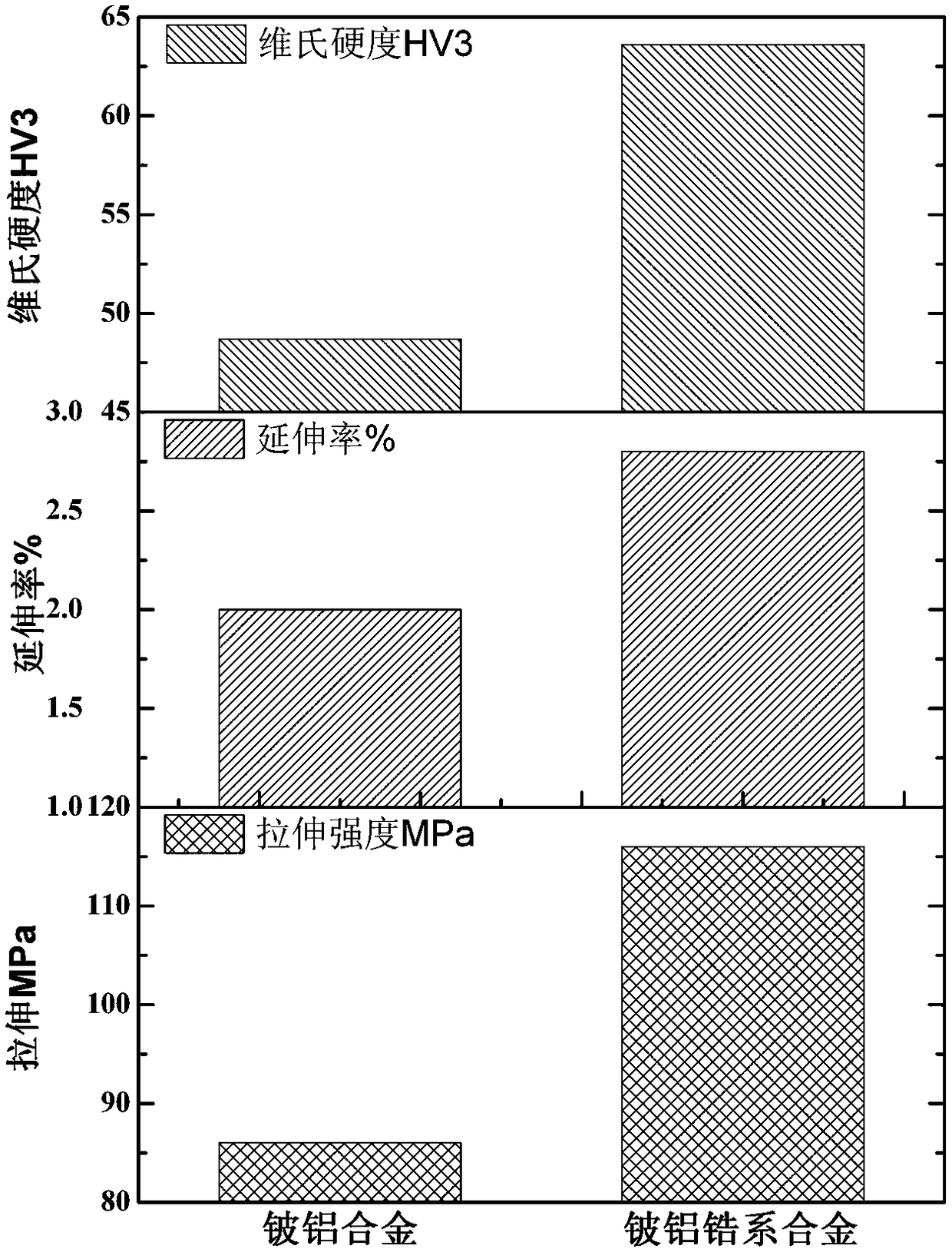

[0041] In the beryllium-aluminum-zirconium multi-element alloy of this embodiment, the mass percentages of each component are as follows: the content of beryllium is 62%, the content of aluminum is 36.8%, the content of zirconium is 0.8%, and the content of added elements is 0.4%. Among the added alloying elements, the magnesium content is 0.2%, and the nickel content is 0.2%.

[0042] The preparation process is as follows.

[0043] (1) Preparation of beryllium aluminum alloy

[0044] Calculate the amount of metal beryllium and aluminum required in advance, and increase the amount of aluminum by 1.40% on the basis of the calculated value. Put the metal beryllium and aluminum raw materials into the alumina ceramic crucible in the vacuum induction melting furnace, in which the aluminum material is placed in the lower part of the crucible, and the beryllium material is placed in the upper part of the crucible, and then the casting of beryllium aluminum alloy is started. The cast...

Embodiment 2

[0050] The preparation process is as follows.

[0051] (1) Preparation of beryllium aluminum alloy

[0052] Calculate the amount of metal beryllium and aluminum required in advance, and increase the amount of aluminum input by 1.48~1.53% on the basis of the calculated value. Put the metal beryllium and aluminum raw materials into the hemispherical water-cooled copper mold crucible in the vacuum arc melting furnace, in which the aluminum material is placed in the lower part of the crucible, and the beryllium material is placed in the upper part of the crucible, and then the casting of beryllium aluminum alloy is started. The casting process is: melting and casting The minimum vacuum in the forehearth is 1×10 -2 ~8×10 -3 Pa, and then the protective gas argon is charged to 0.10 MPa, the melting current is 420 amperes, the number of melting times is 5 times, and the melting time is 5 minutes each time.

[0053] (2) After being released from the furnace, the beryllium alloy ingo...

Embodiment 3

[0060] In the beryllium-aluminum-zirconium multi-element alloy of this embodiment, the mass percentages of each component are as follows: the content of beryllium is 65%, the content of aluminum is 33.2%, the content of zirconium is 0.8%, and the content of added elements is 1.0%. Among the added alloying elements, the zinc content is 0.8%, and the platinum content is 0.2%.

[0061] The preparation process is as follows.

[0062] (1) Preparation of beryllium aluminum alloy

[0063] Calculate the amount of metal beryllium and aluminum required in advance, and increase the amount of aluminum input by 1.73~1.78% on the basis of the calculated value. Put the metal beryllium and aluminum raw materials into the hemispherical water-cooled copper mold crucible in the vacuum arc melting furnace, in which the aluminum material is placed in the lower part of the crucible, and the beryllium material is placed in the upper part of the crucible, and then the beryllium aluminum alloy arc me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com