Production process of anti-ultraviolet flame-retardant and light-resistant curtain fabric

A production process, anti-ultraviolet technology, applied in the direction of light-resistant fiber, flame-retardant fiber, biochemical fiber treatment, etc., can solve the problems of fading and degradation of curtain fabrics, affecting the color and pattern of curtains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

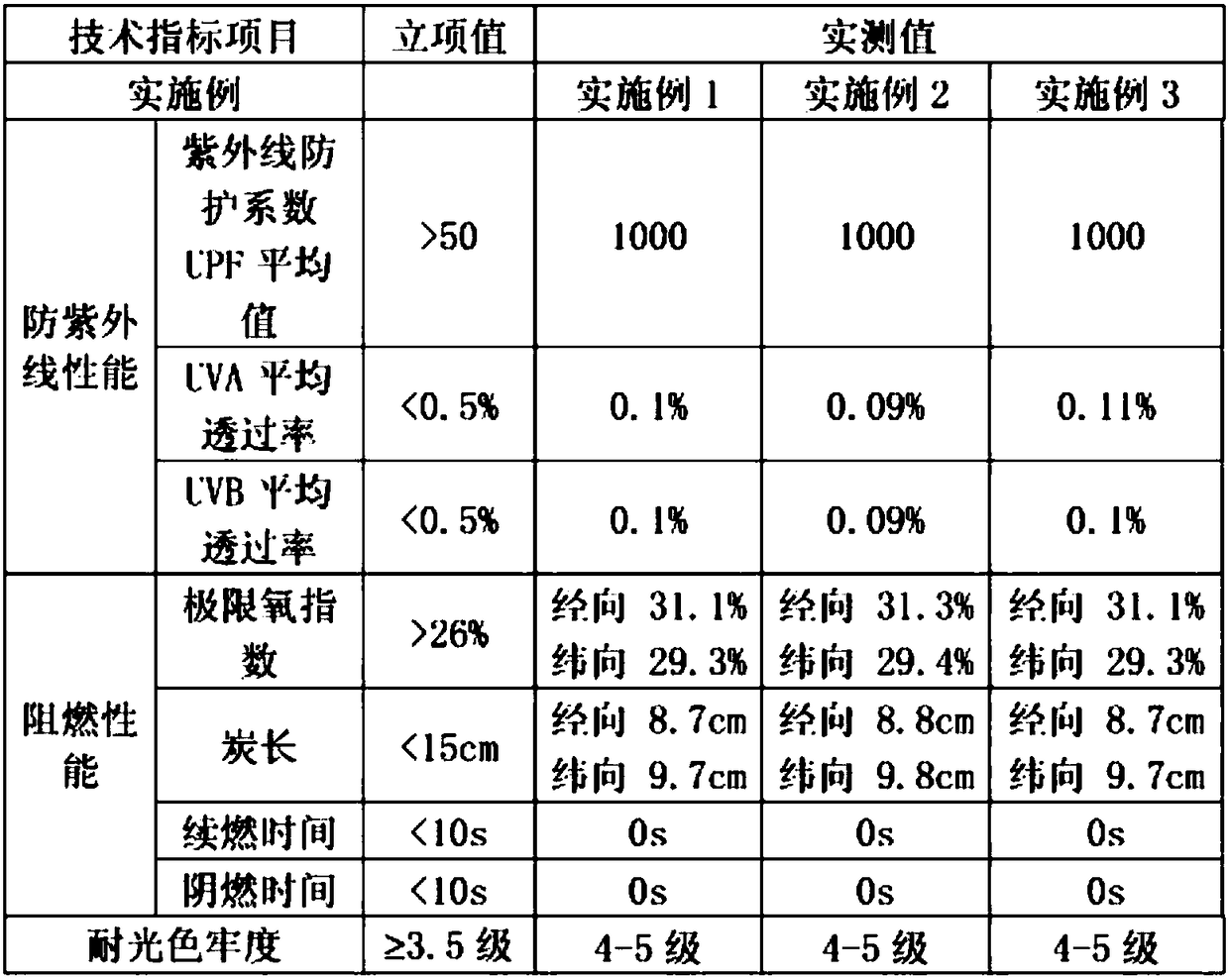

Embodiment 1

[0017] 3 parts by weight of phosphorus-free flame-retardant polyester fibers, 5 parts by weight of polyacrylonitrile fibers, 2 parts by weight of fine sulfur cotton, and 0.3 parts by weight of flame-retardant nylon are mixed and spun into yarns, and then the yarns are spun into Semi-finished fabrics;

[0018] Weigh each raw material separately and configure it into a finishing solution. The components of the finishing solution are as follows: paint 45g / L, paint white FTW 4g / L, acrylate adhesive 15g / L, urea 20g / L, glycerin 2g / L, Gemini Cationic softener 40g / L, flame retardant 3g / L, micronano oxide 15g / L, alkyl polyoxyethylene ether succinate sulfonate 1g / L, tribenzylphenol polyoxyethylene ether 2.5g / L L;

[0019] Add the penetrating agent JFC to the above finishing solution, so that the JFC content in the finishing solution reaches 1g / L. Put the above-mentioned semi-finished fabric into the finishing solution for two dipping and two rolling. The rolling rate is 75%. Re-baking...

Embodiment 2

[0021] 3 parts by weight of phosphorus-free flame-retardant polyester fibers, 5 parts by weight of polyacrylonitrile fibers, 2 parts by weight of fine sulfur cotton, and 0.3 parts by weight of flame-retardant nylon are mixed and spun into yarns, and then the yarns are spun into Semi-finished fabrics;

[0022] Weigh each raw material respectively and configure it into a finishing solution. The components of the finishing solution are as follows: paint 50g / L, paint white FTW 3g / L, acrylate adhesive 25g / L, urea 15g / L, glycerin 2.5g / L, Gemini cationic softener 38g / L, flame retardant 3.5g / L, micronano oxide 8g / L, alkyl polyoxyethylene ether succinate sulfonate 1.5g / L, tribenzylphenol polyoxyethylene ether 2.5g / L;

[0023] Add the penetrating agent JFC to the above finishing solution, so that the JFC content in the finishing solution reaches 1g / L. Put the above-mentioned semi-finished fabric into the finishing solution for two dipping and two rolling. The rolling rate is 75%. Re-b...

Embodiment 3

[0025] 3.5 parts by weight of phosphorus-free flame-retardant polyester fiber, 4 parts by weight of polyacrylonitrile fiber, 2 parts by weight of refined sulfur cotton, and 0.3 parts by weight of flame-retardant nylon are mixed and spun into yarn, and then the yarn is spun into Semi-finished fabrics;

[0026] Weigh each raw material separately and configure it into a finishing solution. The components of the finishing solution are as follows: paint 55g / L, paint white FTW 2g / L, acrylate adhesive 30g / L, urea 20g / L, glycerin 3g / L, Gemini Cationic softener 35g / L, flame retardant 4g / L, micronano oxide 2.5g / L, alkyl polyoxyethylene ether succinate sulfonate 2g / L, tribenzylphenol polyoxyethylene ether 2.5g / L;

[0027] Add the penetrating agent JFC to the above-mentioned finishing solution, so that the JFC content in the finishing solution reaches 0.5g / L. Put the above-mentioned semi-finished fabric into the finishing solution for two dipping and two rolling. Re-baking at 145°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com