Anchor rod ultimate anti-pull force design parameter optimization design method under different expansion agent contents in rock and soil masses

A technology of design parameters and optimized design, applied in the direction of excavation, sheet pile wall, foundation structure test, etc., to achieve the effect of improving the pullout resistance of anchor bolts, broad engineering application prospects and promotion value, and reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

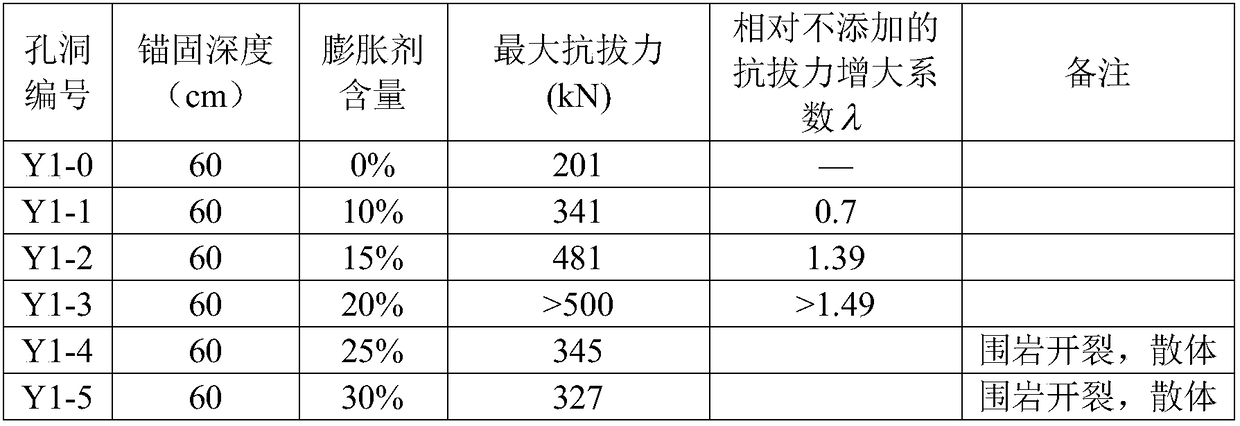

Embodiment 1

[0035] Step 1: Select experimental materials such as cement, expansion agent, and steel bars according to actual engineering needs, and select a suitable anchorage slope;

[0036] Step 2: Drill holes at an angle of 60° between the slope and the slope surface, with a depth of 60cm and a diameter of 8cm;

[0037] Step 3: Prepare two groups of cement slurries with different expansive agent content according to the experimental requirements, the first group, cement 100g, expansive agent 0g; the second group, cement 850g, expansive agent 150g, three groups of materials are heated with water (50 degrees Celsius ) in an appropriate amount to be prepared into cement slurry without expansion agent and expansion cement slurry with expansion agent content of 15%;

[0038] Step 4: Put a steel bar in the middle of the slope hole, first pour 57.5cm high expansion cement slurry with different contents into the hole, and then pour 2.5cm high plain cement slurry to seal;

[0039] Step 5: Afte...

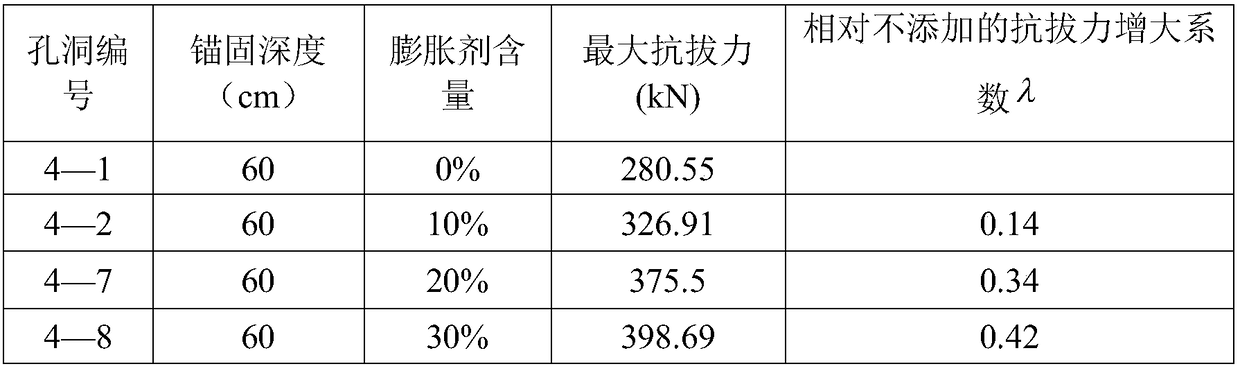

Embodiment 2

[0045] Step 1: Select experimental materials such as cement, expansion agent, and steel bars according to actual engineering needs, and select a suitable anchorage slope;

[0046] Step 2: Drill holes at an angle of 60° between the slope and the slope surface, with a depth of 60cm and a diameter of 8cm;

[0047] Step 3: Prepare two groups of cement slurries with different expansion agent contents according to the experimental requirements. Group 1, cement 100g, expansion agent 0g; Group 2, cement 850g, expansion agent 150g. Add an appropriate amount of warm water (fifty degrees Celsius) to the three groups of materials to prepare the cement slurry without expansion agent and the expansion cement slurry with expansion agent content of 15%;

[0048] Step 4: Put a steel bar in the middle of the slope hole, first pour 57.5cm high expansion cement slurry with different contents into the hole, and then pour 2.5cm high plain cement slurry to seal;

[0049] Step 5: After the cement is...

Embodiment 3

[0055] Step 1: Select experimental materials such as cement, expansion agent, and steel bars according to actual engineering needs, and select a suitable anchorage slope;

[0056] Step 2: Drill holes at an angle of 60° between the slope and the slope surface, with a depth of 60cm and a diameter of 8cm;

[0057] Step 3: Prepare two groups of cement slurries with different expansion agent contents according to the experimental requirements. The first group contains 100g of cement and 0g of expansion agent; the second group contains 850g of cement and 150g of expansion agent. Add an appropriate amount of warm water (fifty degrees Celsius) to the three groups of materials to prepare the cement slurry without expansion agent and the expansion cement slurry with expansion agent content of 15%;

[0058] Step 4: Put a steel bar in the middle of the slope hole, first pour 57.5cm high expansion cement slurry with different contents into the hole, and then pour 2.5cm high plain cement sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com