Epoxy chloropropane modified Fe3O4 magnetic nanometer material as well as preparation and application thereof

A technology of epichlorohydrin and magnetic nanometers, applied in other chemical processes, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve problems such as low yield, complicated preparation process, and long process flow, and achieve adsorption capacity Large, excellent adsorption performance, the effect of excellent heavy metal ion adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of epichlorohydrin modified Fe 3 o 4 Magnetic nanomaterial, its preparation method comprises the following steps:

[0033] 1) Add 0.834g FeSO 4 ·7H 2 O was added to 10mL epichlorohydrin, and stirred evenly in a water bath at 50°C; 2)

[0034] Add 0.502g KOH to the mixed solution obtained in step 1), and continue to stir to obtain the reaction solution after 30min;

[0035] 3) Seal the reaction solution in a reaction kettle, react at 120°C for 4 hours, anneal and cool, collect the solid particles by magnetic separation, and wash them with 3×10mL ethanol and 3×10mL H 2 After O is washed to neutral, it is air-dried at room temperature to obtain the epichlorohydrin modified Fe 3 o 4 magnetic nanomaterials.

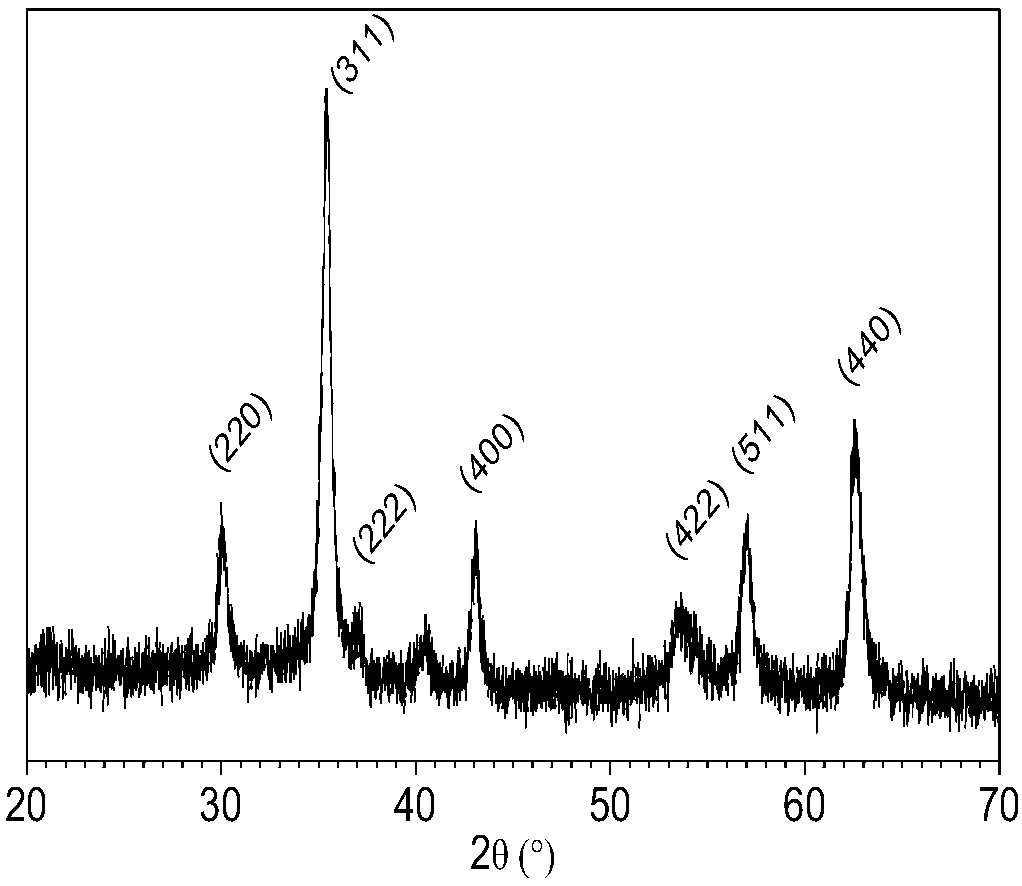

[0036] The X-ray diffraction analysis result of the product obtained in this embodiment is shown in figure 1 , the characteristic peaks in the figure are related to Fe 3 o 4 It is consistent with the standard spectrum (JCPDS No.65-3107), indicating that...

Embodiment 2

[0042] A kind of epichlorohydrin modified Fe 3 o 4 Magnetic nanomaterial, its preparation method comprises the following steps:

[0043] 0.834g FeSO 4 ·7H 2 O was added to 10 mL of epichlorohydrin, and stirred evenly in a water bath at 50 °C. Then add 0.502g KOH, and continue to stir for 30min to obtain a reaction solution. The reaction solution was sealed in a reaction kettle and reacted at 110°C for 4 hours, then annealed and cooled, and the resulting solid particles were collected by magnetic separation, and washed with 3×10mL ethanol and 3×10mL H 2 After O is washed to neutral, room temperature is air-dried to obtain the described epichlorohydrin modified Fe 3 o 4 Magnetic Nanomaterials.

Embodiment 3

[0045] A kind of epichlorohydrin modified Fe 3 o 4 Magnetic nanomaterial, its preparation method comprises the following steps:

[0046] 0.834g FeSO 4 ·7H 2 O was added to 10 mL of epichlorohydrin, and stirred evenly in a water bath at 50 °C. Then add 0.502g KOH, and continue to stir for 30min to obtain a reaction solution. The reaction solution was sealed in a reaction kettle and reacted at 170°C for 4 hours, then annealed and cooled, and the resulting solid particles were collected by magnetic separation, and washed with 3×10mL ethanol and 3×10mL H 2 After O is washed to neutral, room temperature is air-dried to obtain the described epichlorohydrin modified Fe 3 o 4 Magnetic Nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

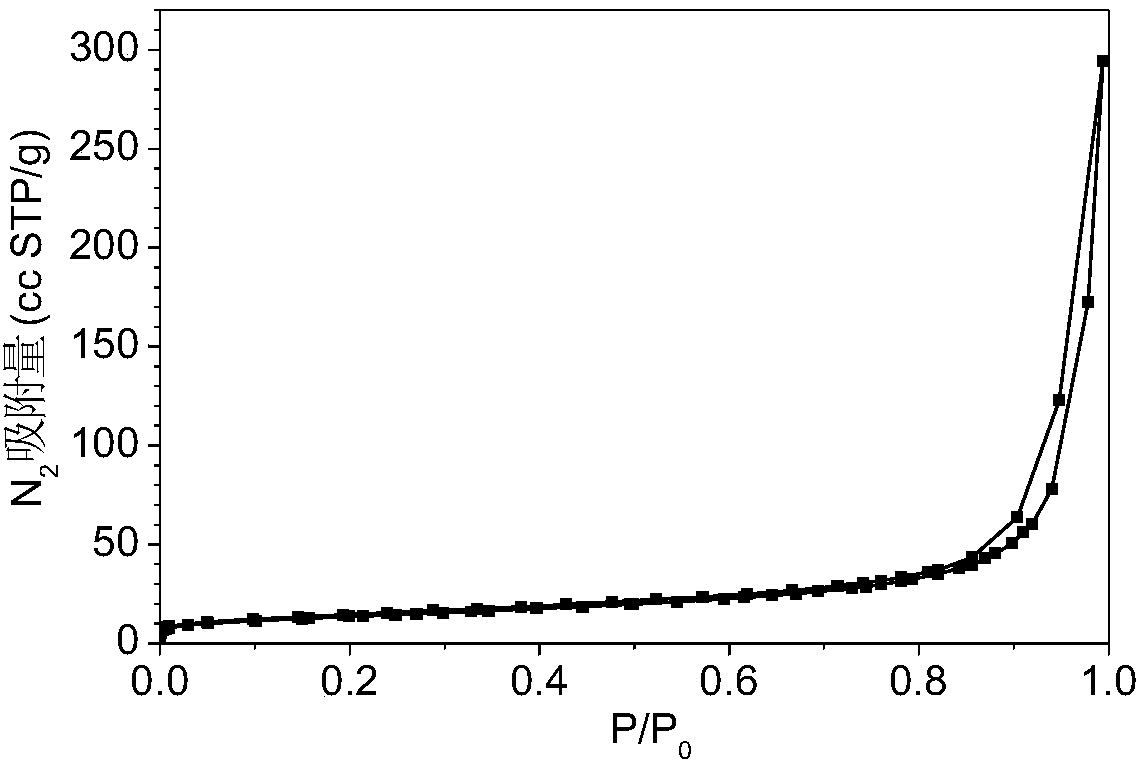

| Surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com