A composite functional diaphragm and its preparation method

A composite function, diaphragm technology, applied in the field of engineering plastics, can solve the problems of differences in thermal expansion coefficient of shrinkage, cracked layers, diaphragm deformation, etc., to achieve the effects of low cost, strong adhesion and easy deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

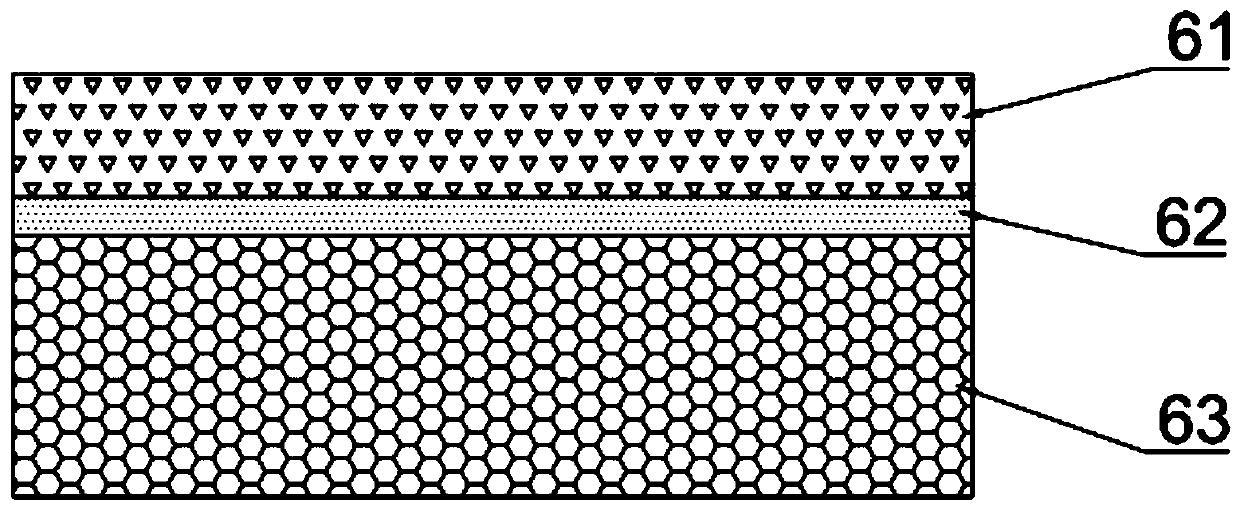

[0035] Such as figure 1 Shown, a kind of composite function diaphragm comprises polycarbonate PC layer 63, polymethyl methacrylate PMMA layer 61 and is positioned at the composite function between polycarbonate PC layer 63 and polymethyl methacrylate PMMA layer 61 Layer 62; the raw material of the composite functional layer 62 is a silicone compatible coupling agent with two active functional groups, methyl and phenyl.

[0036] In another embodiment, the composite functional layer 62 has a thickness of 5 μm, and may also be 1 μm or 10 μm.

[0037] In another embodiment, the raw material of the composite functional layer 62 further includes a nanoscale anti-ultraviolet and blue light absorber.

[0038] In another embodiment, the raw material of the composite functional layer 62 further includes a nanoscale conductive antistatic agent.

[0039] In another embodiment, the raw materials of the composite functional layer 62 further include a nanoscale anti-ultraviolet and blue li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com