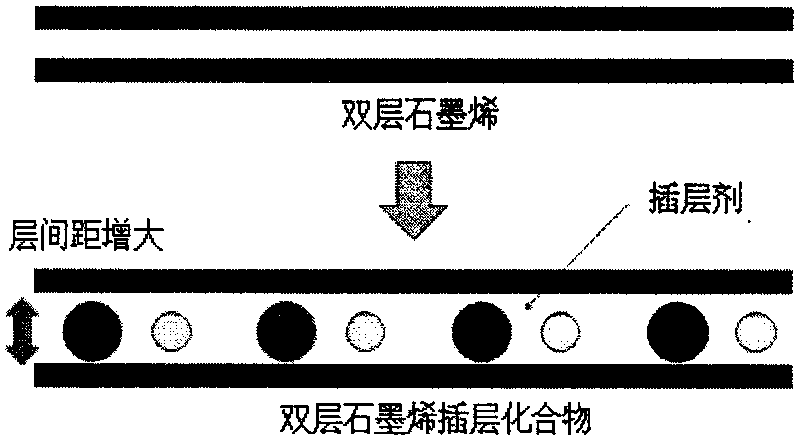

Preparation method of double-layer graphene intercalation compound

A double-layer graphene and graphite intercalation technology, which is applied in the direction of graphene, carbon compounds, chemical instruments and methods, etc., can solve the problems of difficulty in obtaining first-order compounds and poor stability of synthetic products, and achieve low equipment requirements, Effects in simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

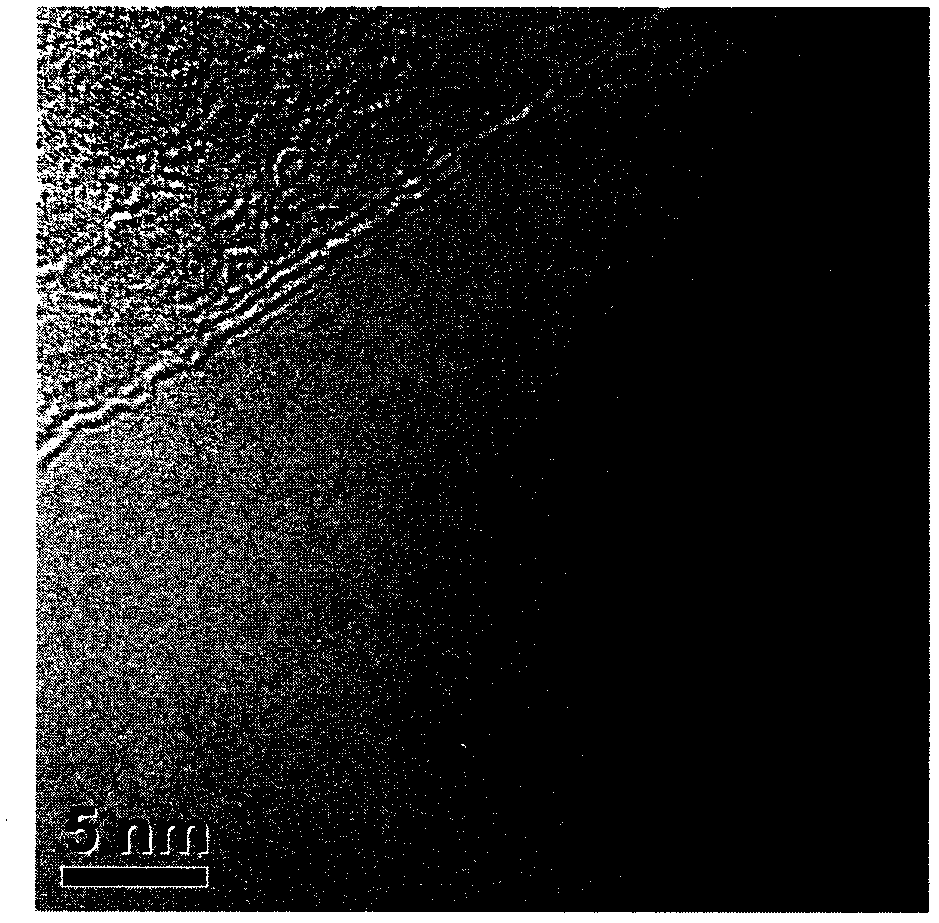

Examples

Embodiment 1

[0023] (1) Mix 30g of iodine chloride and 50mg of expanded graphite evenly, fill it with protective gas Ar, and seal it in a 50mL glass bottle.

[0024] (2) Place in an oil bath environment at 160°C and heat for 48 hours to prepare a second-order graphite intercalation compound.

[0025] (3) The graphite intercalation compound was quickly taken out from the glass bottle and filtered.

[0026] (4) Put all the graphite intercalation compounds into the quartz boat quickly, and place the quartz boat in an argon protective atmosphere.

[0027] (5) Heat the quartz boat to 800°C for 5 minutes.

[0028] (6) After the reaction is completed, the sample is taken out, and the sample is cleaned to obtain a double-layer graphene powder aggregate.

[0029] (7) 0.3g anhydrous FeCl 3 Mix evenly with 0.05g double-layer graphene powder, and vacuum seal it in a 20mL vacuum ampoule.

[0030] (8) Put the vacuum ampoule into the muffle furnace, raise the temperature to 380° C. for 1 hour, and ma...

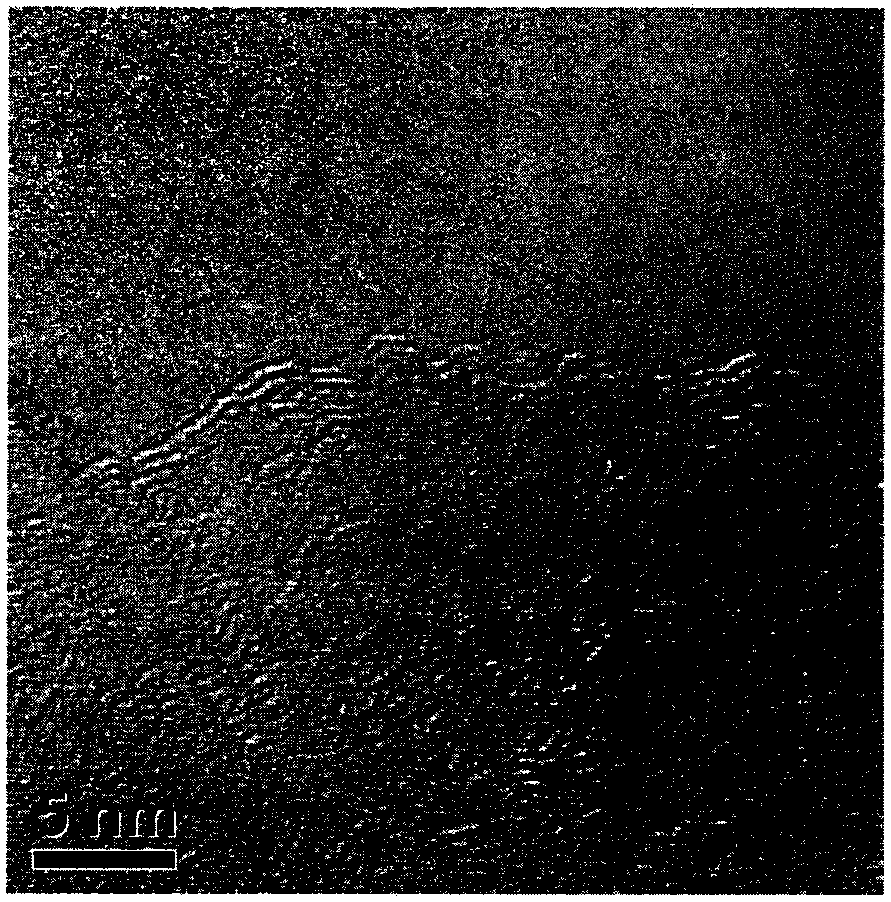

Embodiment 2

[0035] (1) Mix 30g of iodine chloride and 50mg of high-temperature oriented pyrolytic graphite evenly, fill it with protective gas Ar, and seal it in a 50mL glass bottle.

[0036] (2) Place in an oil bath environment at 160°C and heat for 48 hours to prepare a second-order graphite intercalation compound.

[0037] (3) The graphite intercalation compound was quickly taken out from the glass bottle and filtered.

[0038] (4) Put all the graphite intercalation compounds into the quartz boat quickly, and place the quartz boat in an argon protective atmosphere.

[0039] (5) Heat the quartz boat to 800°C for 5 minutes.

[0040] (6) After the reaction is completed, the sample is taken out, and the sample is cleaned to obtain a double-layer graphene powder aggregate.

[0041] (7) 0.3g anhydrous FeCl 3 Mix evenly with 0.05g double-layer graphene powder, and vacuum seal it in a 20mL vacuum ampoule.

[0042] (8) Put the vacuum ampoule into the muffle furnace, raise the temperature to...

Embodiment 3

[0045] (1) Mix 30g of iodine chloride and 50mg of expanded graphite evenly, fill it with protective gas Ar, and seal it in a 50mL glass bottle.

[0046] (2) Place in an oil bath environment at 160°C and heat for 48 hours to prepare a second-order graphite intercalation compound.

[0047] (3) The graphite intercalation compound was quickly taken out from the glass bottle and filtered.

[0048] (4) Put all the graphite intercalation compounds into the quartz boat quickly, and place the quartz boat in an argon protective atmosphere.

[0049] (5) Heat the quartz boat to 1000°C for 5 minutes.

[0050] (6) After the reaction is completed, the sample is taken out, and the sample is cleaned to obtain a double-layer graphene powder aggregate.

[0051] (7) 0.6g anhydrous FeCl 3 Mix evenly with 0.1g double-layer graphene powder, and vacuum-tightly seal it in a 20mL vacuum ampoule.

[0052] (8) Put the vacuum ampoule into the muffle furnace, raise the temperature to 380° C. for 0.5 h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com