Film-coated aluminum alloy template and preparation method thereof

A technology of aluminum alloy template and aluminum alloy substrate, which is applied in conductive coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of destroying the appearance of concrete, affecting the acceptance of project quality, and inability to remove rust and dirt, and achieve improvement. The effect of demoulding, solving the sticking phenomenon, and improving the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

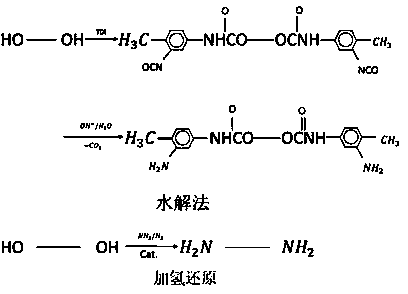

[0023] The relatively specific preparation method of the A component is: the prepolymer formed by the reaction of polyether polyol and isocyanate is hydrolyzed under alkaline conditions to generate a carbamate-containing intermediate, and then hydrogen gas is introduced to further heat and decompose to obtain a terminal Amino polyether, the heating temperature is controlled at 16-23 ℃ to inhibit the formation of polyurea, and then add the chain extender. Preferably, the mass fraction composition of polyether polyol, isocyanate and chain extender in component A is 1:0.75:1.3; the mass fraction composition of chain extender and isocyanate in component B is 1:1.3.

[0024] The above method is a combination of hydrolysis method and direct catalytic reductive amination method, and its characteristic is that the introduced chain extender can make the reaction of A and B components become slower, and its reaction formula is as follows:

[0025]

[0026] Polyether modified silicone...

Embodiment 1

[0043] A component 49.4kg, A component 49.4kg, polyether modified silicone oil 1kg, dimethyl silicone oil 0.2kg, organic solvent is toluene. Component A is placed in a container separately, and polyether modified silicone oil, dimethyl silicone oil and organic solvent are added to component B, stirred at high speed for 10 minutes, mixed with the above component A after stirring evenly, sprayed on the aluminum alloy after 3 minutes of high-speed stirring On the substrate, the thickness of the polyurea coating layer is 0.2mm.

Embodiment 2

[0045] A component 48.7kg, A component 48.7kg, polyether modified silicone oil 2kg, dimethyl silicone oil 0.6kg, organic solvent is toluene. Component A is placed in a container separately, and polyether modified silicone oil, dimethyl silicone oil and organic solvent are added to component B, stirred at high speed for 10 minutes, mixed with the above component A after stirring at high speed for 3 minutes, and then coated on aluminum alloy On the substrate, the thickness of the polyurea coating layer is 0.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com