Soil repairing agent and soil repairing method

A soil remediation agent and soil remediation technology, applied in the field of soil remediation agents, can solve the problems of high cost and poor treatment effect, and achieve the effects of low treatment cost, improved soil environment and good treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

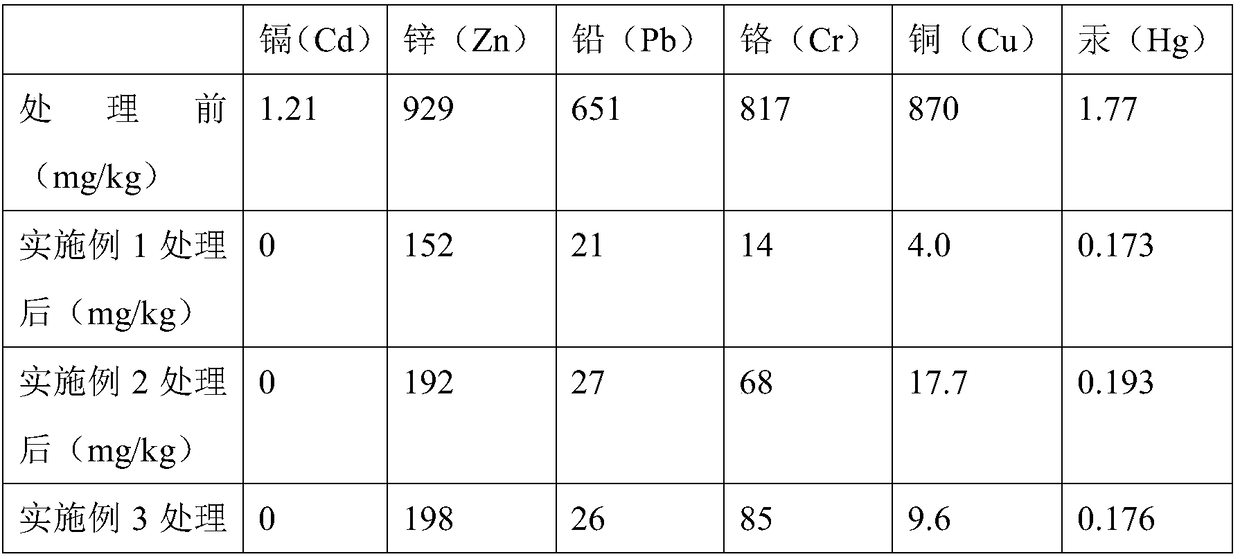

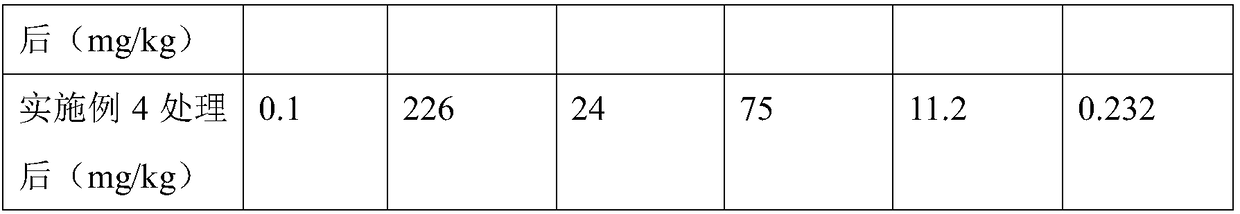

Embodiment 1

[0019] Prepare raw materials by the following parts by weight:

[0020] 10 parts of sodium sulfide, 10 parts of ferric oxide, 10 parts of ferric sulfate, 10 parts of calcium oxide, 2 parts of sodium sulfate, 2 parts of calcium nitrate, 10 parts of calcium hydroxide, 10 parts of bentonite, 10 parts of cement.

[0021] Preparation method: Mix the above-mentioned raw materials to obtain the soil restoration agent.

[0022] The test soil was collected from a heavy metal-polluted area, and the heavy metal content in the soil surface of this area was higher than the third-level standard of the "Soil Environmental Quality Standard" (GB15618-1995). Repair according to the actual situation of pollution

[0023] Soil remediation: collect heavy metal contaminated soil, then evenly mix 1% weight of soil remediation agent on the surface contaminated by heavy metal soil, and then carry out soil plowing to fully mix the soil remediation agent and heavy metal contaminated soil, and it will b...

Embodiment 2

[0026] Prepare raw materials by the following parts by weight:

[0027] 15 parts of sodium sulfide, 20 parts of ferric oxide, 15 parts of ferric sulfate, 18 parts of calcium oxide, 1 part of sodium sulfate, 2 parts of calcium nitrate, 15 parts of bentonite.

[0028] Preparation method: Mix the above-mentioned raw materials to obtain the soil restoration agent.

[0029] The test soil was collected from a heavy metal-polluted area, and the heavy metal content in the soil surface of this area was higher than the third-level standard of the "Soil Environmental Quality Standard" (GB15618-1995). Repair according to the actual situation of pollution

[0030] Soil remediation: collect heavy metal contaminated soil, then evenly mix 1% weight of soil remediation agent on the surface contaminated by heavy metal soil, and then carry out soil plowing to fully mix the soil remediation agent and heavy metal contaminated soil, and it will be completed after 5-10 days Soil heavy metal remedi...

Embodiment 3

[0033] Prepare raw materials by the following parts by weight:

[0034] 20 parts of sodium sulfide, 18 parts of ferric oxide, 20 parts of iron sulfate, 15 parts of calcium oxide, 1 part of sodium sulfate, 15 parts of calcium hydroxide, 18 parts of bentonite, and 20 parts of cement.

[0035] Preparation method: Mix the above-mentioned raw materials to obtain the soil restoration agent.

[0036] The test soil was collected from a heavy metal-polluted area, and the heavy metal content in the soil surface of this area was higher than the third-level standard of the "Soil Environmental Quality Standard" (GB15618-1995). Repair according to the actual situation of pollution

[0037] Soil remediation: collect heavy metal contaminated soil, then evenly mix 1% weight of soil remediation agent on the surface contaminated by heavy metal soil, and then carry out soil plowing to fully mix the soil remediation agent and heavy metal contaminated soil, and it will be completed after 5-10 days...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com