Method for preparing lavender oil through enzymatic curing and application of lavender oil

A technology of lavender oil and lavender, which is applied in the directions of essential oils/fragrances, fat production, fermentation, etc., can solve the problems of characteristic aroma masking, high production cost, and large irritation, and achieve improved taste, coordinated smoke, and reduced irritation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

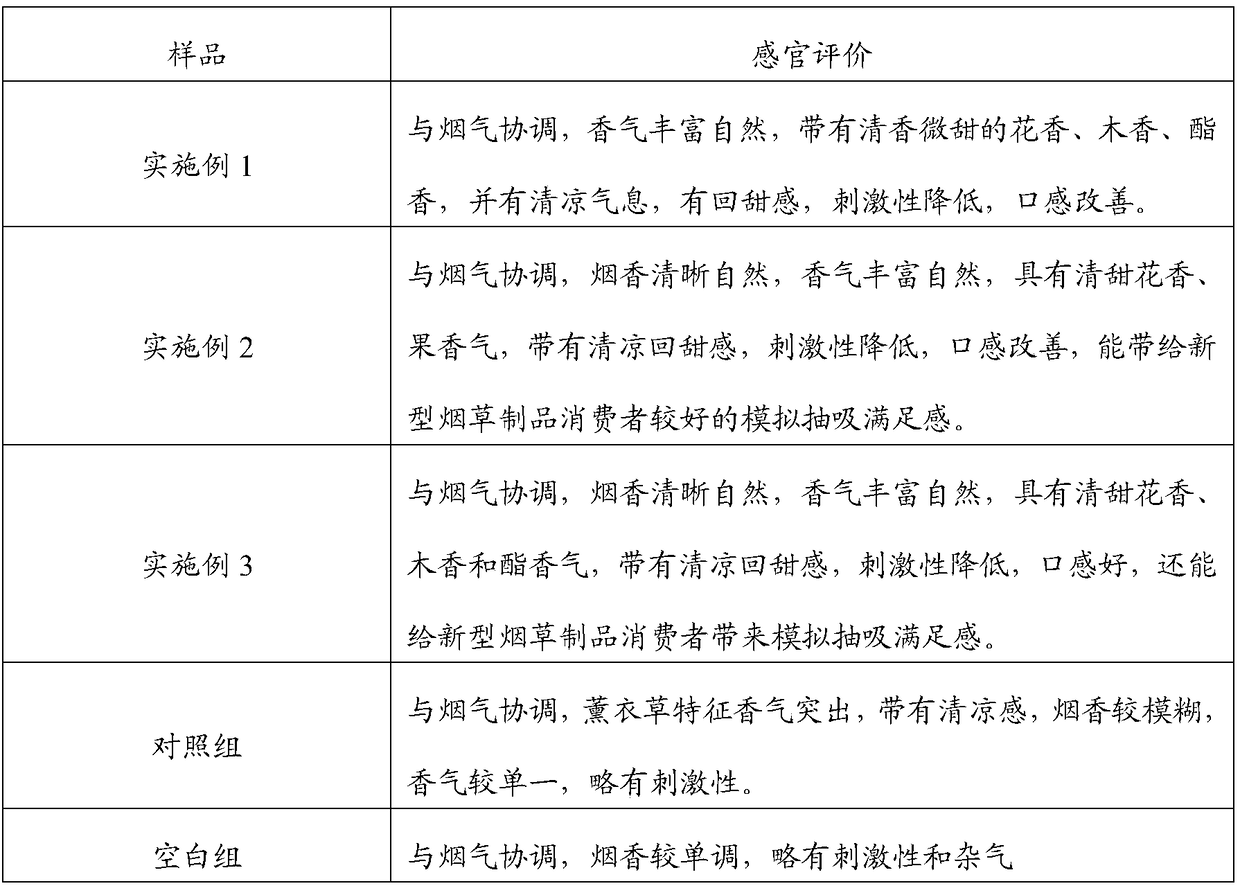

Examples

Embodiment 1

[0020] A method for enzymatically producing fragrance and preparing lavender oil, comprising the steps of:

[0021] (1) Low-temperature ultrasonic pretreatment: Mix the dried lavender flower spikes and water evenly at a mass ratio of 1:10, pour them into a low-temperature ultrasonic extractor at 0°C, ultrasonic frequency 25KHz, ultrasonic power 300W, turn on magnetic stirring, and ultrasonicate for 20 minutes;

[0022] (2) Incubation and fermentation: Pour the lavender flower spike ultrasonic aqueous solution and flower spike residue into the fermentation extraction tank, add maleic acid and caffeic acid (food grade, accounting for 0.2% of the dried flower spike quality of lavender, and the proportioning ratio between them is as follows: The mass ratio is 1:2), adding compound enzyme preparations (β-glucosidase, β-xylosidase, laccase, cellulase, food grade, the enzyme activity is 500u / g, 10000u / g, 10000u / g respectively , 20000u / g, 20000u / g, the ratio between the enzyme prepara...

Embodiment 2

[0026] A method for enzymatically producing fragrance and preparing lavender oil, comprising the steps of:

[0027] (1) Low-temperature ultrasonic pretreatment: Mix the dried lavender flower spikes and water evenly at a mass ratio of 1:15, pour them into a low-temperature ultrasonic extractor, set at 4°C, ultrasonic frequency 25KHz, ultrasonic power 700W, turn on magnetic stirring, and ultrasonicate for 10 minutes;

[0028] (2) Incubation and fermentation: the lavender flower spike ultrasonic aqueous solution and the flower spike residue are poured in the fermentation extraction tank, add maleic acid, citrate, stearic acid (food grade, account for 0.4% of the dried flower spike quality of lavender, between The ratio between them is 1:1:2 according to the mass ratio), adding compound enzyme preparations (β-glucosidase, β-xylosidase, laccase, cellulase, food grade, the enzyme activity is 5000u / g, 2000u / g, 30000u / g, 40000u / g, the ratio between the enzyme preparations is 1:4:2:0.5...

Embodiment 3

[0032] A method for enzymatically producing fragrance and preparing lavender oil, comprising the steps of:

[0033] (1) Low-temperature ultrasonic pretreatment: mix the dried lavender flower spikes and water evenly at a mass ratio of 1:20, pour them into a low-temperature ultrasonic extractor, set at 8°C, ultrasonic frequency 25KHz, ultrasonic power 1300W, turn on magnetic stirring, and ultrasonicate for 5 minutes;

[0034] (2) Incubation and fermentation: Pour the lavender flower spike ultrasonic aqueous solution and the flower spike residue into the fermentation extraction tank, add maleic acid, caffeic acid, salicylic acid, citrate, stearic acid (food grade, accounting for lavender dried flowers) 0.5% of the ear mass, the proportioning ratio is 1:0.5:0.5:1:1 by mass ratio), adding compound enzyme preparations (β-glucosidase, β-xylosidase, laccase, cellulase, Food grade, enzyme activity is divided into 10000u / g, 50000u / g, 50000u / g, 50000u / g, the ratio between enzyme preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com