Method of selectively leaching lead sulphide from lead sulphide bearing material

A selective, sulfide technology, applied in the direction of process efficiency improvement, etc., can solve problems such as lead recovery not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

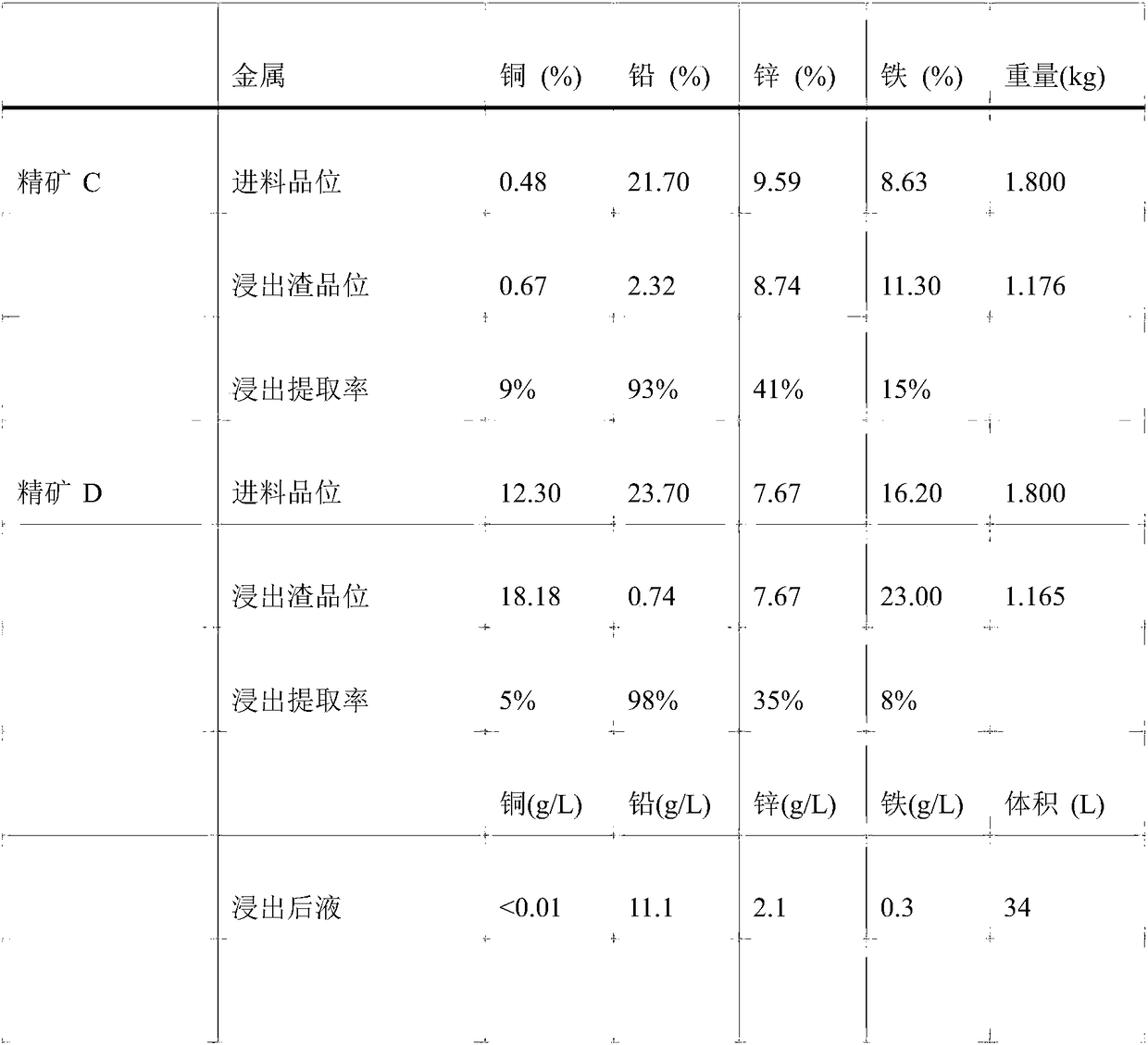

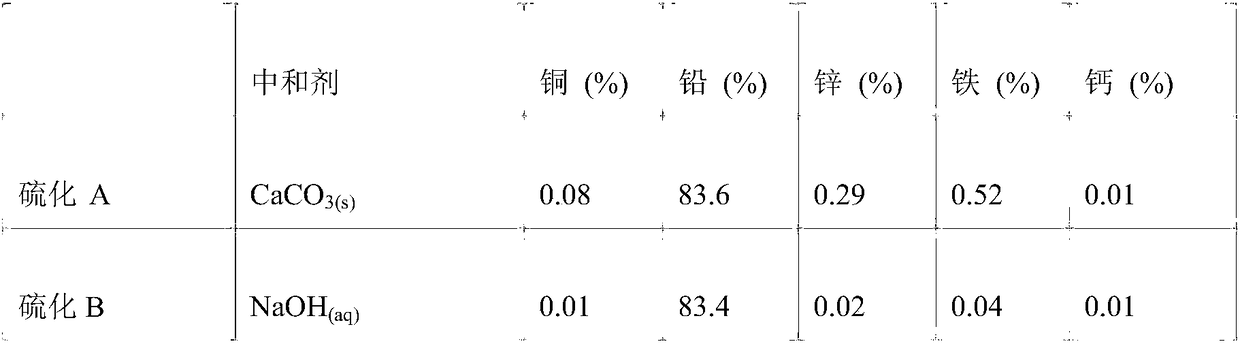

Examples

Embodiment Construction

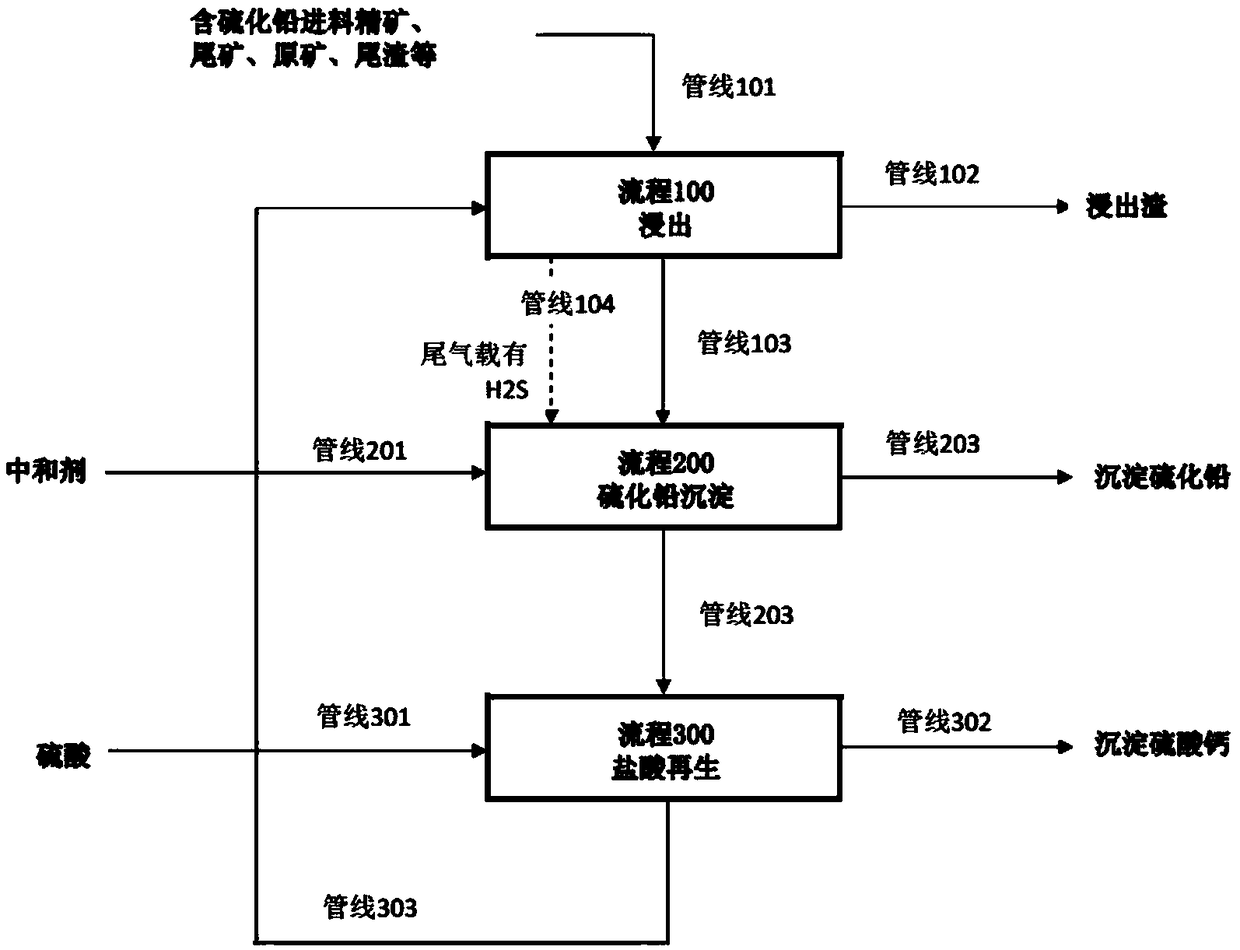

[0025] In the following detailed description, the accompanying drawings are set forth in detail and are incorporated as a part of the detailed description. The detailed description and illustrations in the claims do not constitute the claims to be limited accordingly. Other embodiments may be utilized, and other changes may be made without departing from the spirit or scope of the subject matter. We can readily appreciate that, as described herein, and as depicted in this accompanying drawing, the various aspects of the present disclosure can be arranged, substituted, combined, separated, and designed in various configurations, all These are included in this disclosure.

[0026] Process description

[0027] figure 1 A process flow diagram in the form of a block diagram is shown. This process illustrates one embodiment of the selective leaching of lead from ores, concentrates, tailings or other lead-containing sulphide materials.

[0028] The flow diagram includes three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com