Method for researching influence on formation of surface microstructure on basis of irradiating different materials by laser

A technology of laser irradiation and microstructure, which is applied in the direction of material analysis, material analysis, and measuring devices through optical means, can solve the problems of research methods without surface convex molding, and achieve easy control, short processing cycle, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the drawings are in simplified form and use inaccurate scales, and are only used for the purpose of conveniently and clearly illustrating the embodiments of the present invention.

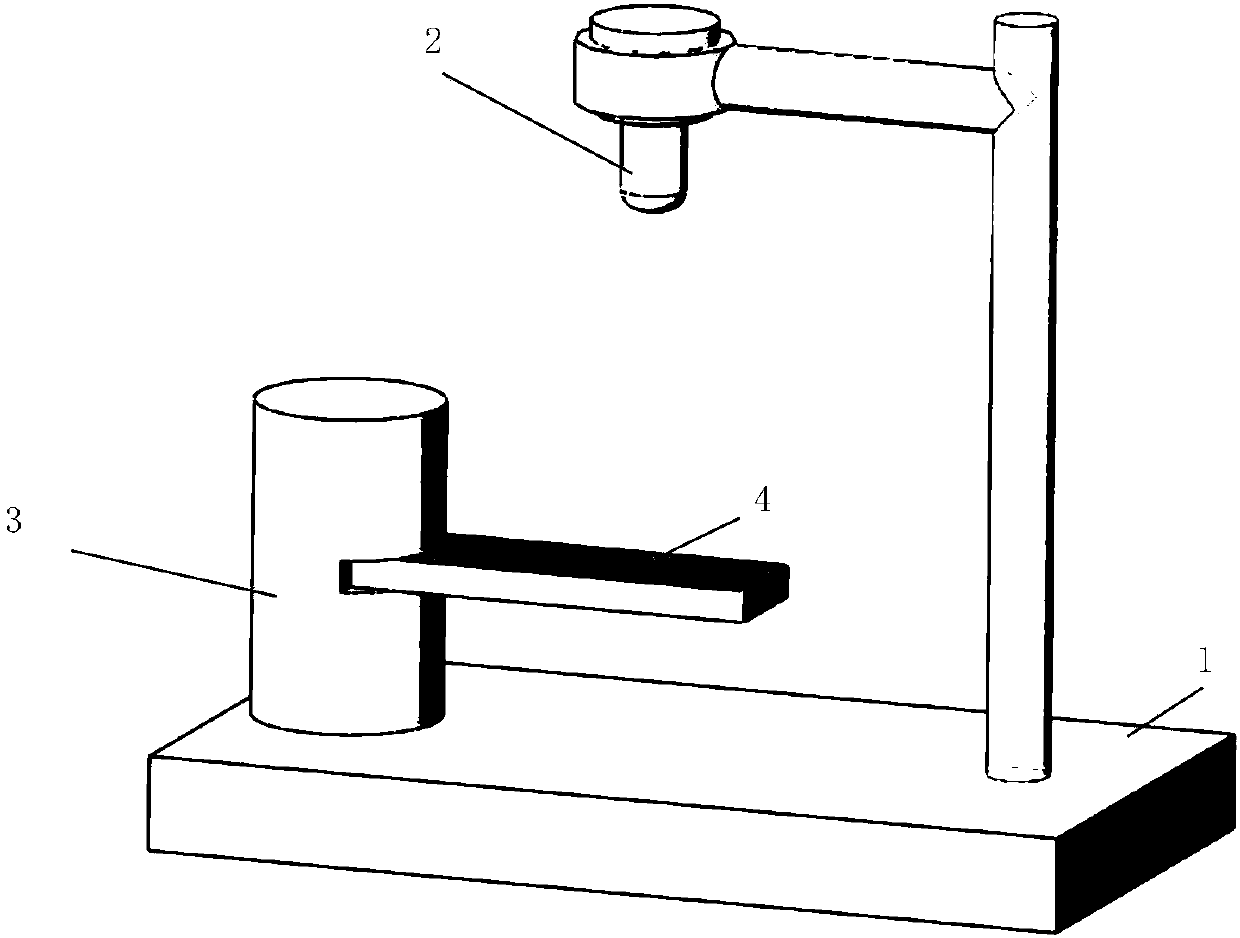

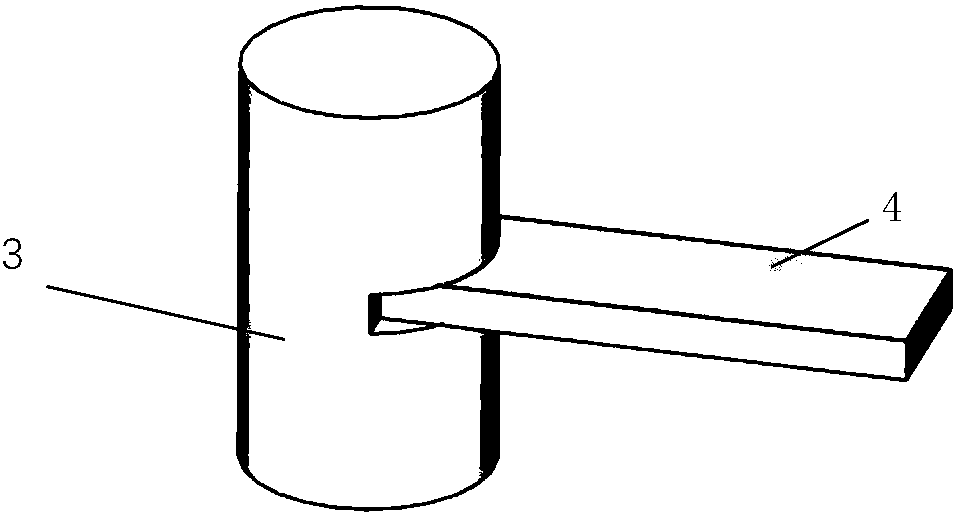

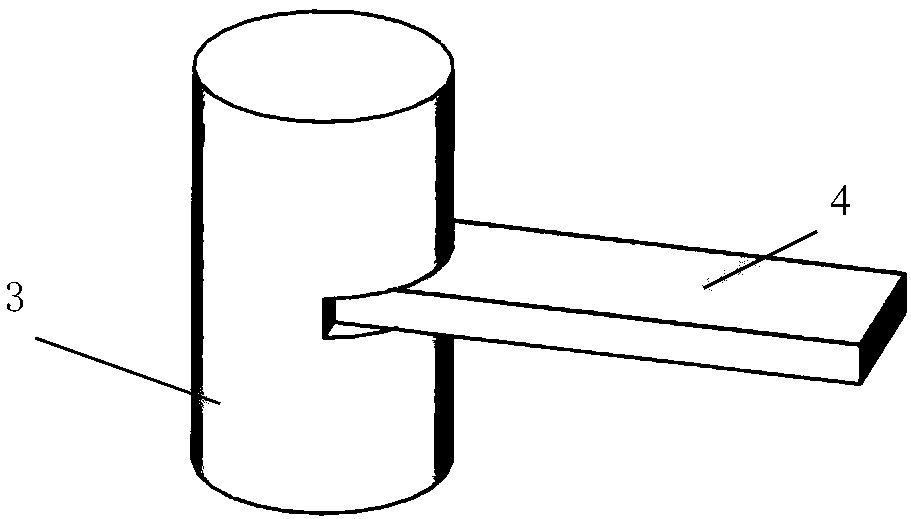

[0038] build as figure 1 The experimental equipment shown includes a test bench 1, a femtosecond laser transmitter 2, and a clamping plate 3 for a silicon substrate. The clamping plate 3 is equivalent to a clamping facility with a dimensional structure, and is used to clamp a silicon substrate 4 on the micron scale. The thermal diffusion affects the experimental results, and the thermal insulation material is selected. The experimental bench 1 is used to fix the femtosecond laser emitter 1 and the silicon substrate clamping plate 3 , and can ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com