Back contact crystalline silicon heterojunction solar cell and preparation method thereof

A technology for solar cells and crystalline silicon, applied in the field of solar cells, can solve problems such as poor stability, and achieve the effect of simple process and suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

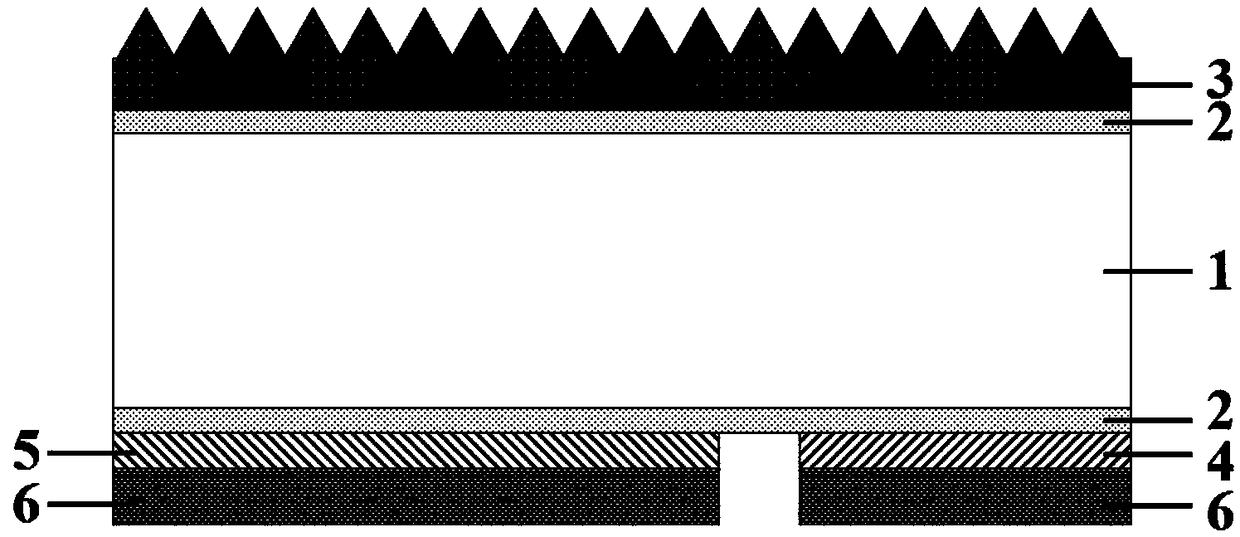

[0038] A back-contact crystalline silicon heterojunction solar cell, the solar cell comprising: a silicon substrate 1, a passivation layer 2, an antireflection film 3, a metal oxide reflector 4, a metal electrode 6, LiF x Film 5, the passivation layer 2 includes the first passivation layer and the second passivation layer, the material of the passivation layer 2 is SiO 2 .

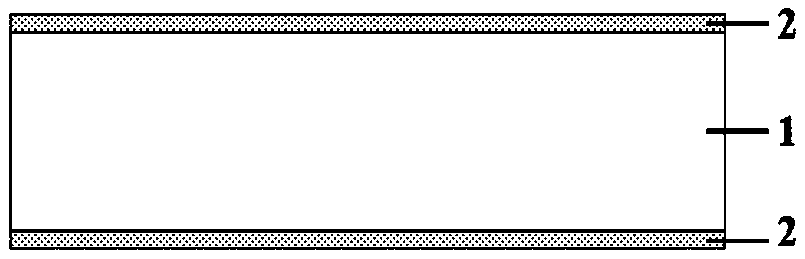

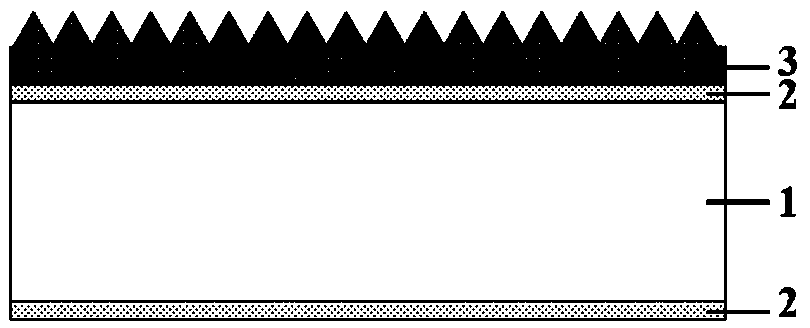

[0039] The first passivation layer is deposited on the upper surface of the silicon substrate 1 .

[0040] The antireflection film is deposited 3 on the upper surface of the first passivation layer.

[0041] The second passivation layer is deposited on the lower surface of the silicon substrate 1, and the silicon substrate 1 is a single crystal silicon wafer.

[0042] The metal oxide reflector 4 is deposited on one end of the lower surface of the second passivation layer, and the LiF x A thin film 5 is deposited on the other end of the lower surface of the second passivation layer.

[0043] The metal e...

Embodiment 2

[0058] A back-contact crystalline silicon heterojunction solar cell, the solar cell comprising: a silicon substrate 1, a passivation layer 2, an antireflection film 3, a metal oxide reflector 4, a metal electrode 6, LiF x Film 5, the passivation layer 2 includes the first passivation layer and the second passivation layer, the material of the passivation layer 2 is Al 2 o 3 .

[0059] The first passivation layer is deposited on the upper surface of the silicon substrate 1 .

[0060] The antireflection film is deposited 3 on the upper surface of the first passivation layer.

[0061] The second passivation layer is deposited on the lower surface of the silicon substrate 1, and the silicon substrate 1 is a single crystal silicon wafer.

[0062] The metal oxide reflector 4 is deposited on one end of the lower surface of the second passivation layer, and the LiF x A thin film 5 is deposited on the other end of the lower surface of the second passivation layer.

[0063] The met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com