Novel power lithium battery aluminum-plastic film

A lithium battery and aluminum-plastic film technology, which is applied in the field of aluminum-plastic film for new power lithium batteries, can solve the problems of inner layer composite strength drop and detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

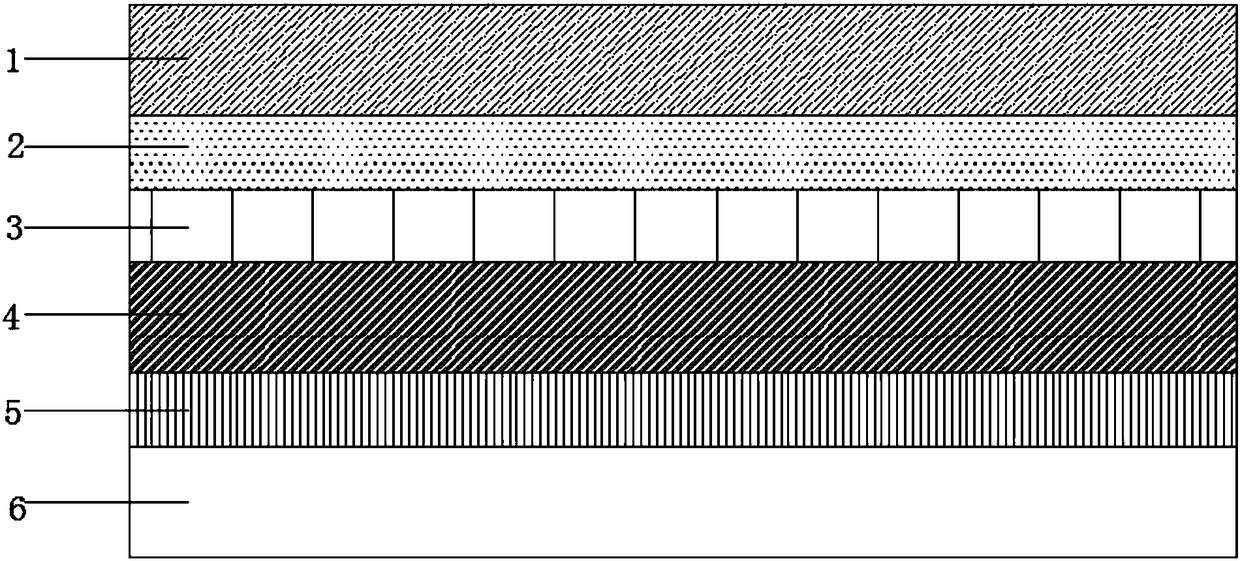

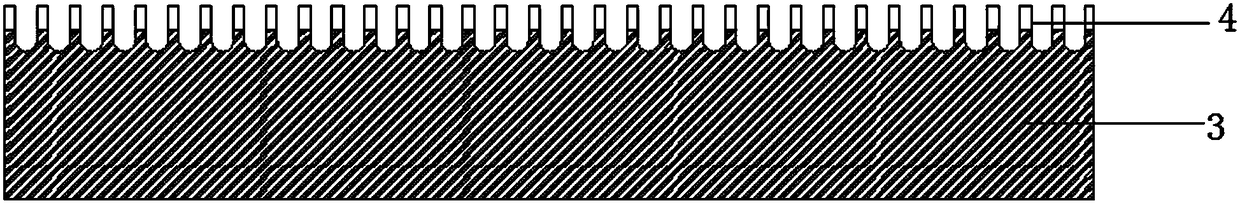

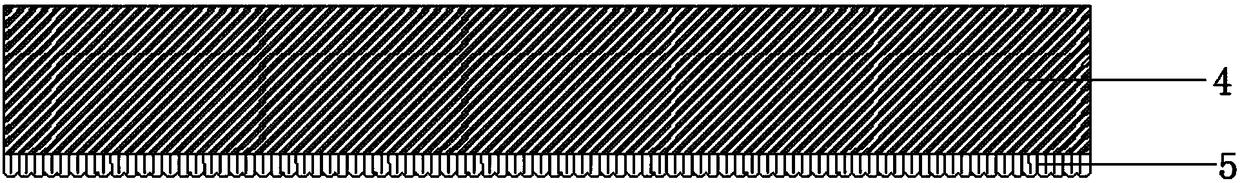

[0020] An aluminum-plastic composite film, whose structure from the outer surface to the inner layer is a protective outer layer 1, an adhesive layer 2, a treatment layer 3, an aluminum foil layer 4, a special protective layer 5, a multifunctional inner layer 6, and a protective outer layer 1 It is a polyamide film with a thickness of 25 μm; the bonding layer 2 is a polyurethane adhesive; the treatment layer 3 is a nano-microporous treatment layer, and the treatment layer 3 penetrates into the middle aluminum foil layer 4 without forming a penetration, and the nanopore diameter is 100~300nm, the penetration depth is 300~700nm; the aluminum foil layer 4 is a 40μm alloy aluminum foil; the special protective layer 5 is a dense film layer formed by homogeneous particle arrangement, and the particle size is 200~300nm; the multifunctional inner layer 6 uses poly Acrylic material, thickness 46μm.

Embodiment 2

[0022] An aluminum-plastic composite film, whose structure from the outer surface to the inner layer is a protective outer layer 1, an adhesive layer 2, a treatment layer 3, an aluminum foil layer 4, a special protective layer 5, a multifunctional inner layer 6, and a protective outer layer 1 It is a polyamide film with a thickness of 25 μm; the bonding layer 2 is a polyurethane adhesive; the treatment layer 3 is a nano-microporous treatment layer, and the treatment layer 3 penetrates into the middle aluminum foil layer 4 without forming a penetration, and the nanopore diameter is 100~300nm, the penetration depth is 300~700nm; the aluminum foil layer 4 is a 40μm alloy aluminum foil; the special protective layer 5 is a dense film layer formed by homogeneous particle arrangement, and the particle size is 200~300nm; the multifunctional inner layer 6 uses poly Vinyl material, thickness 46μm.

Embodiment 3

[0024] An aluminum-plastic composite film, whose structure from the outer surface to the inner layer is a protective outer layer 1, an adhesive layer 2, a treatment layer 3, an aluminum foil layer 4, a special protective layer 5, a multifunctional inner layer 6, and a protective outer layer 1 It is a polyethylene terephthalate film with a thickness of 25 μm; the bonding layer 2 is a polyurethane adhesive; the treatment layer 3 is a nano-microporous treatment layer, and the treatment layer 3 penetrates into the middle aluminum foil layer 4 without forming Penetration, the nanopore diameter is 100~300nm, and the penetration depth is 300~700nm; the aluminum foil layer 4 is a 40μm alloy aluminum foil; the special protective layer 5 is a dense film layer formed by homogeneous particle arrangement, and the particle size is 200~300nm; The multifunctional inner layer 6 is made of polypropylene material with a thickness of 85 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com