Method for preparing aspartame based on exocarpium citri grandis

A technology for turning tangerine red and sweetener, which is applied in the field of sweetener preparation, can solve the problems of low product yield, difficulty in repeating, expensive source of raw materials, etc., and achieve the effect of high yield and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

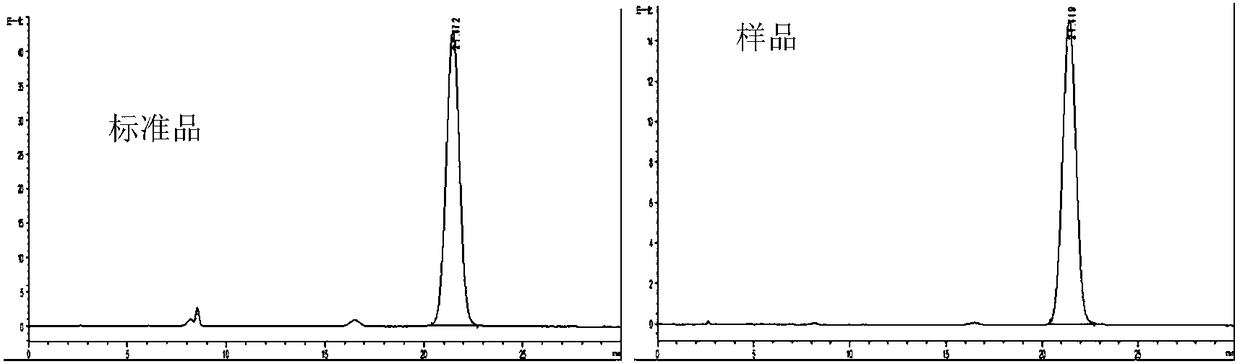

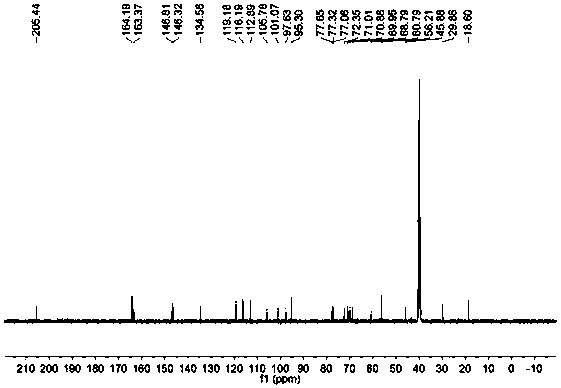

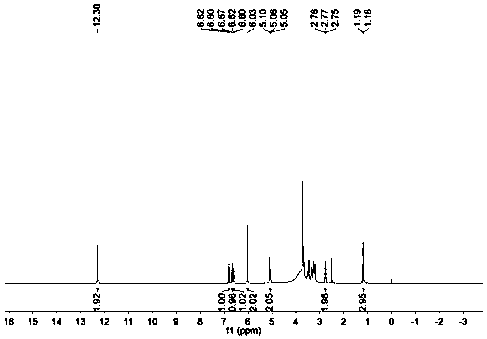

Image

Examples

Embodiment 1

[0029] In this example, the operation method for preparing the novel sweetener neohesperidin dihydrochalcone is carried out according to the following three steps: Preparation of root bark acetophenone-4'-neohesperidin: weigh 8.0 g of naringin Place in a three-necked flask, add 120mL of sodium hydroxide or potassium hydroxide with a mass fraction of 15%, and pass through N 2 Heat to 145-150°C under inert gas protection and reflux for 2 hours. After cooling, add concentrated hydrochloric acid to adjust the pH to 6.0. A large amount of yellow-white precipitates are formed. Heat the mixture to 120°C, the solid dissolves, and naturally cools to precipitate crystals. Suction filtration, repeated washing with ice water , to obtain 5.6g product root bark acetophenone-4'-neohesperidin;

[0030] Preparation of neohesperidin: Weigh 4.76g of acetophenone-4'-neohesperidin and 1.52g of isovanillin, add 50mL of ethanol, stir at room temperature for 15min, then add catalyst tetrahydropyrrole...

Embodiment 2

[0033] The operation method for preparing the novel sweetener neohesperidin dihydrochalcone in this example is carried out according to the following three steps: Preparation of root bark acetophenone-4'-neohesperidin: weigh 8.0 g of naringin Place in a three-necked flask, add 120mL of sodium hydroxide or potassium hydroxide with a mass fraction of 15%, and pass through N 2 Heat to 145-150°C under inert gas protection and reflux for 2 hours. After cooling, add concentrated hydrochloric acid to adjust the pH to 6.0. A large amount of yellow-white precipitates are formed. Heat the mixture to 120°C, the solid dissolves, and naturally cools to precipitate crystals. Suction filtration, repeated washing with ice water , to obtain 5.7g product root bark acetophenone-4'-neohesperidin;

[0034] Preparation of neohesperidin: Weigh 4.76g of acetophenone-4'-neohesperidin and 1.52g of isovanillin, add 50mL of ethanol, stir at room temperature for 15min, then add catalyst tetrahydropyrrole ...

Embodiment 3

[0037]The operation method for preparing the novel sweetener neohesperidin dihydrochalcone in this example is carried out according to the following three steps: Preparation of root bark acetophenone-4'-neohesperidin: weigh 8.0 g of naringin Place in a three-necked flask, add 120mL of sodium hydroxide or potassium hydroxide with a mass fraction of 15%, and pass through N 2 Heat to 145-150°C under inert gas protection and reflux for 2 hours. After cooling, add concentrated hydrochloric acid to adjust the pH to 6.0. A large amount of yellow-white precipitates are formed. Heat the mixture to 120°C, the solid dissolves, and naturally cools to precipitate crystals. Suction filtration, repeated washing with ice water , to obtain 5.7g product root bark acetophenone-4'-neohesperidin;

[0038] The preparation of neohesperidin: Weigh 4.76g of acetophenone-4'-neohesperidin, 1.52g of isovanillin, add 50mL of ethanol, stir at room temperature for 15min, then add catalyst tetrahydropyrrole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com