a cutting device

A cutting device and piston rod technology, applied in leather punching/punching/cutting, small raw hide/big raw hide/leather/fur treatment, animal husbandry, etc., can solve the problem of leather affecting the cutting effect and save manpower High labor and cutting efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

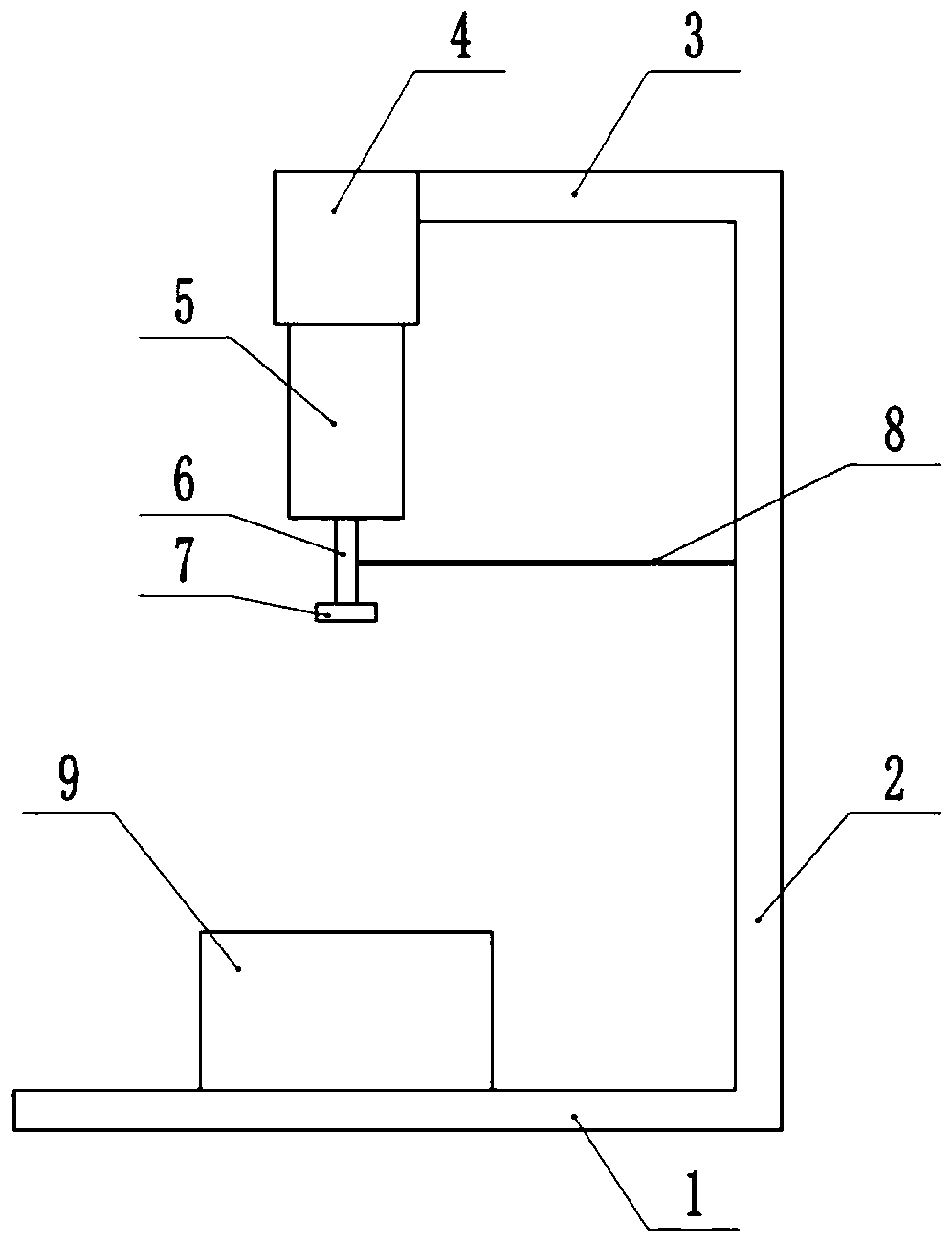

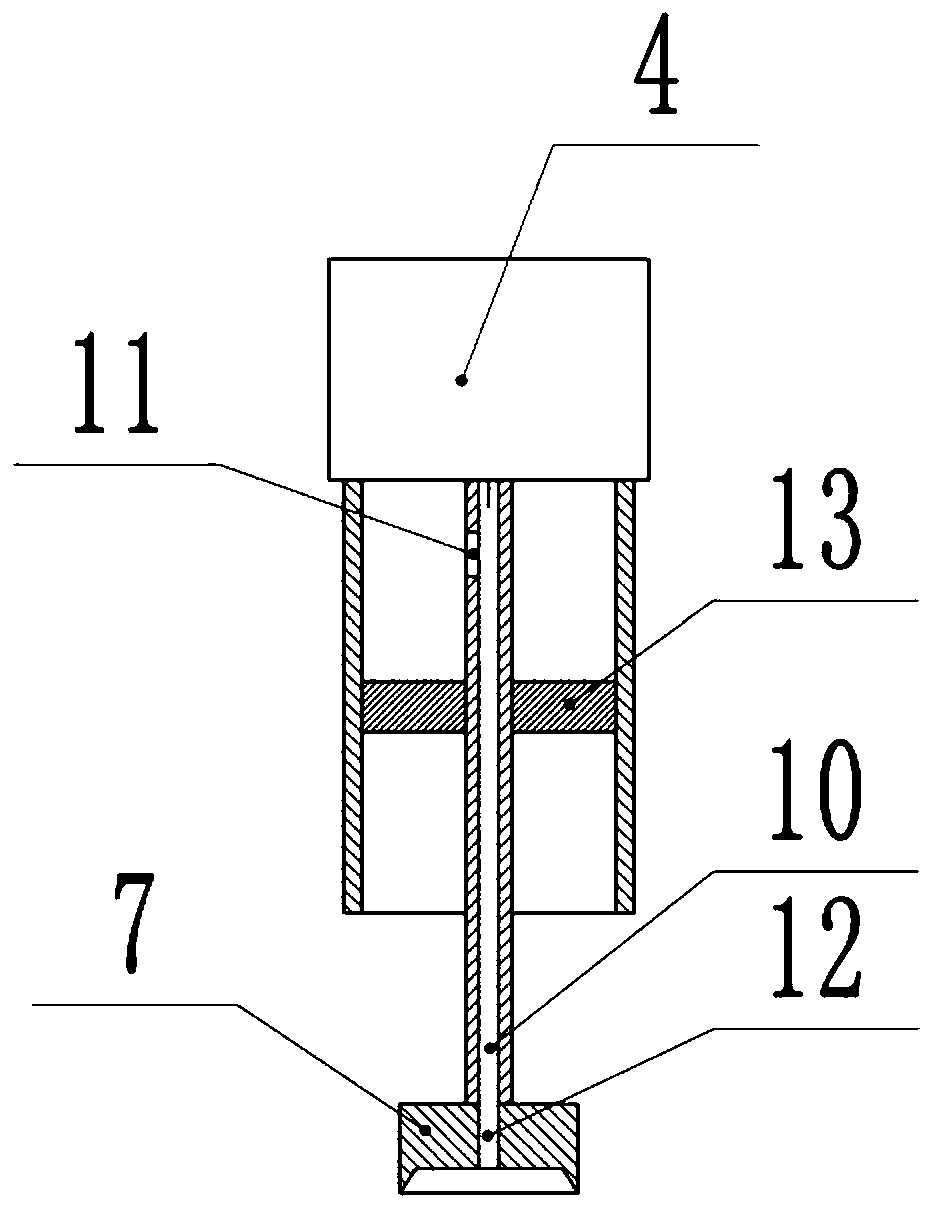

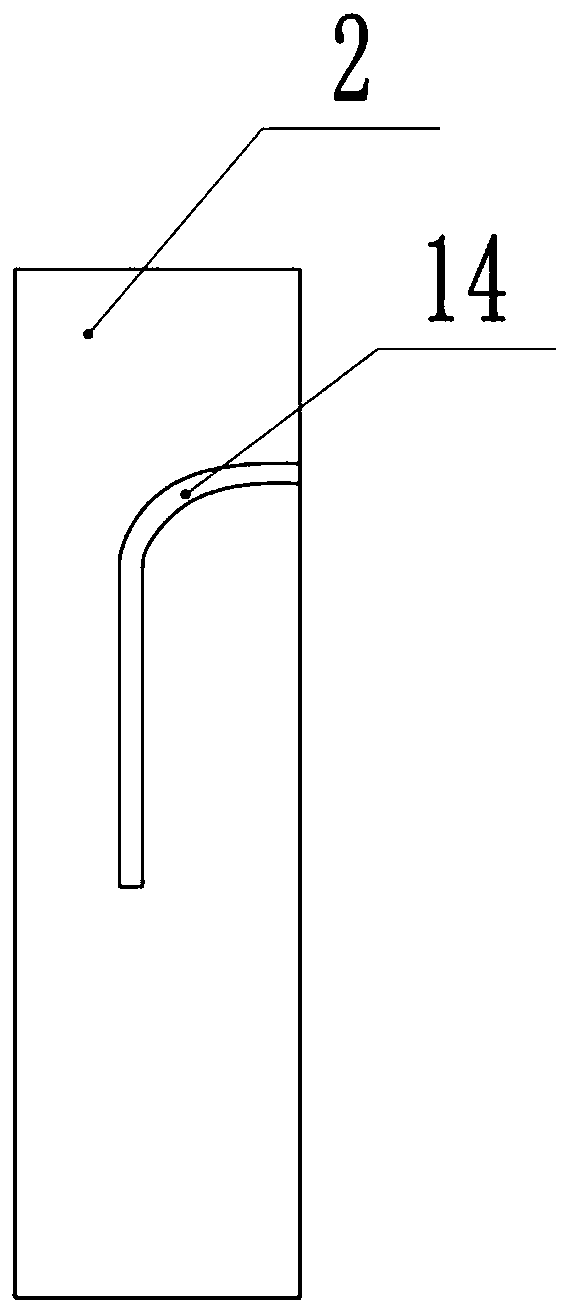

[0025] Such as figure 1 As shown, a cutting device includes a base 1, the left end of the base 1 is connected with a vertical pillar 2 by bolts, the upper end of the pillar 2 is welded with a horizontal beam 3, the beam 3 is equipped with lifting lugs, and the cylinder 4 is mounted on the lifting lugs , cylinder 4 can swing back and forth; figure 2 As shown, the direction of the piston rod 6 of the cylinder 4 is vertically downward, and the inside of the piston rod 6 is provided with a vertical suction pipe 10; Facing the inner depression, an air suction hole 12 is provided on the axis of the annular cutter head 7, and the air suction hole 12 is connected with the air suction pipe 10; 11 apertures. The lower end surface of the cylinder 4 is welded with a sleeve 5, and the sleeve 5 is sealed and welded with the lower end surface of the cylinder 4; the middle part of the piston rod 6 is welded with a push plate 13, and the push plate 13 is slid and sealedly connected with the...

Embodiment 2

[0028] Such as Figure 4 As shown, on the basis of Embodiment 1, the rotary joint is connected between the annular cutter head 7 and the piston rod 6, and an annular groove is set on the outer side of the annular cutter head 7, and the output shaft is installed downward on the cross bar 8 through bolts. The motor 15 is connected to the belt 16 between the output shaft of the motor 15 and the ring cutter head 7, and the belt 16 is installed in the ring groove. When the ring cutter head 7 is not enough for leather cutting, start the motor 15, and the motor 15 Drive the annular cutter head 7 to rotate by belt 16, leather material is fully cut; Install the torsion spring that is used to keep cylinder 4 into vertical state between the upper end of cylinder 4 and crossbeam 3, after cylinder 4 tilts, after torsion When the spring and the piston rod 6 stretch out, the cylinder 4 can be vertically fast, which improves the cutting efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com