Superplastic Ag/SnO2 alloy material and preparation method thereof

An alloy material and superplastic technology, applied in the field of alloy material preparation, can solve the problems of poor processing performance, inability to meet low-cost manufacturing technology, low electrical conductivity, etc., and achieve the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

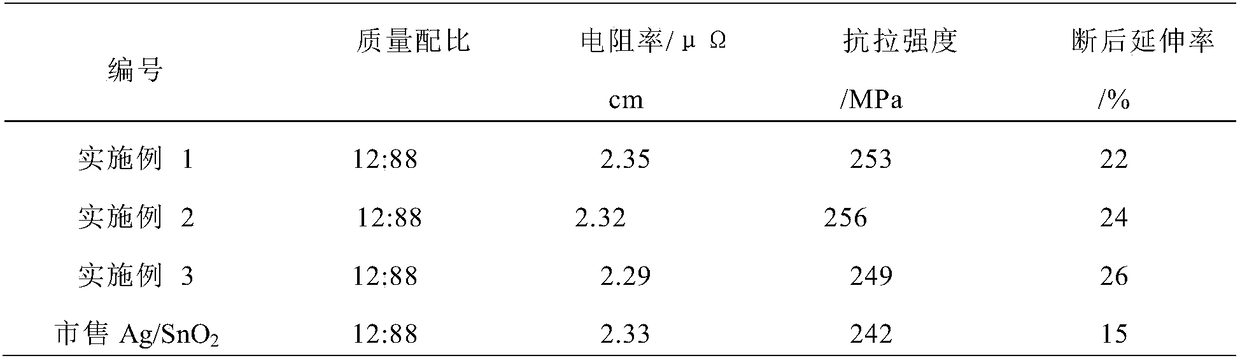

Examples

Embodiment 1

[0028] (1) Preparation of superplastic alloy modified tin oxide composite particles

[0029] Weigh the superplastic alloy TiAl powder and tin oxide powder according to the mass ratio of 0.2:11.8; then introduce the weighed powder into the alumina tank cavity of the ball mill, and add the zirconia grinding medium according to the ball-to-material ratio of 3:1 , and add PEG2000 as a surface activation modifier, and its addition amount is based on 2wt.% of the total amount of materials in the grinding tank. Ball milled for 24 hours under the condition of ball milling speed 200rmp. After the ball milling reaction is complete, the reaction product is washed with alcohol and dried at 80°C. Subsequently, low-temperature sintering treatment was used to remove residual surface activation modifiers and other impurities, wherein the sintering temperature was 200° C., and the sintering time was 8 hours; uniformly dispersed superplastic alloy modified tin oxide composite particles were ob...

Embodiment 2

[0035] (1) Preparation of superplastic alloy modified tin oxide composite particles

[0036] Weigh the superplastic alloy Nb according to the mass ratio of 5:7 3 Al powder and tin oxide powder; then import the weighed powder into the alumina tank cavity of the ball mill, add zirconia grinding media according to the ball-to-material ratio of 10:1, and add sodium stearate as a surface activation modification Active agent, its addition is based on the 2wt.% of the total amount of material in the grinding tank. Ball milled for 8 hours under the condition of ball milling speed 600rmp. After the ball milling reaction is complete, the reaction product is washed with alcohol and dried at 80°C. Subsequently, low-temperature sintering treatment was used to remove residual surface activation modifiers and other impurities, wherein the sintering temperature was 400° C. and the sintering time was 3 hours; uniformly dispersed superplastic alloy modified tin oxide composite particles were ...

Embodiment 3

[0042] (1) Preparation of superplastic alloy modified tin oxide composite particles

[0043] Weigh the superplastic alloy Y-PSZ powder and tin oxide powder according to the mass ratio of 2:10; then import the weighed powder into the alumina tank cavity of the ball mill, and add zirconia according to the ball-to-material ratio of 6:1 Grinding media, and adding sodium dodecylbenzenesulfonate as a surface active modifier, the amount of which is based on 2wt.% of the total amount of materials in the grinding tank. Ball milled for 10 hours under the condition of ball milling speed 400rmp. After the ball milling reaction is complete, the reaction product is washed with alcohol and dried at 80°C. Subsequently, low-temperature sintering treatment was used to remove residual surface activation modifiers and other impurities, wherein the sintering temperature was 300° C., and the sintering time was 5 hours; uniformly dispersed superplastic alloy modified tin oxide composite particles w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com