Embedded type ultrasonic sensor arranged in cement concrete structure

A technology of ultrasonic sensors and concrete structures, which is applied in the direction of measuring ultrasonic/sonic/infrasonic waves, using sound waves/ultrasonic/infrasonic waves to analyze solids, instruments, etc. It can solve the problems that the backing layer cannot be evenly distributed, the mixture is viscous, and it is difficult to stir. Achieve high sensitivity, good waterproof performance and aging resistance, strong signal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

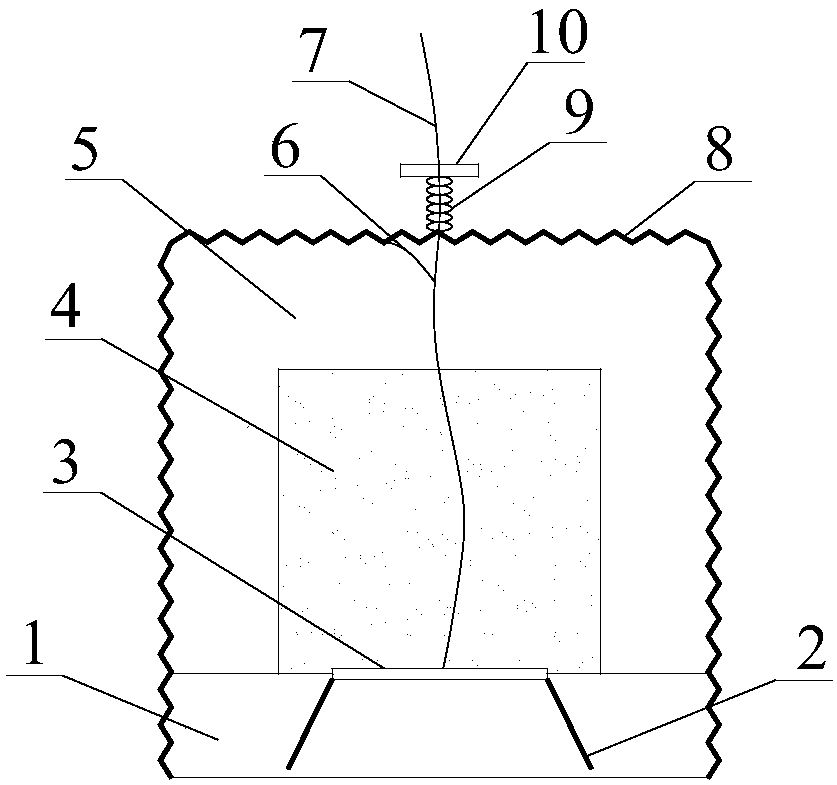

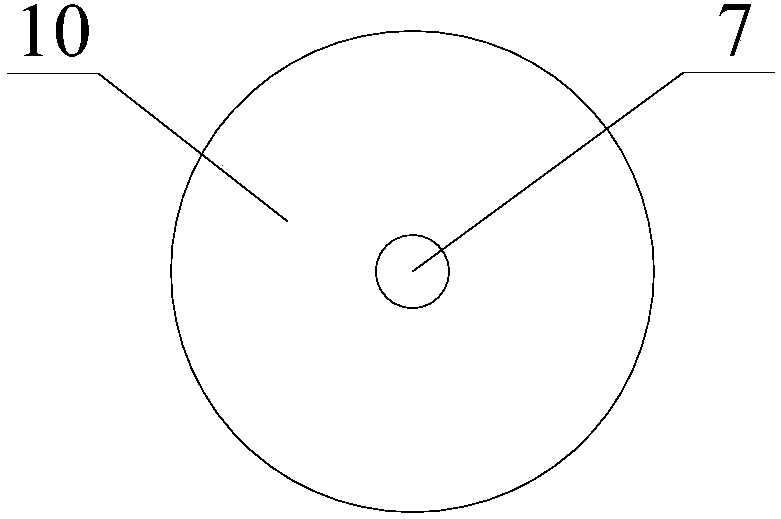

[0029] This example figure 1 An ultrasonic transmitting sensor embedded in cement concrete is provided, and its main structure is composed of a matching layer 1, a front acoustic wave booster 2, a PZT piezoelectric ceramic disc 3, a backing layer 4, an encapsulation layer 5, and a shielding wire 6 , Wire 7, shielding layer 8, compression spring 9 and terminal wire protector 10.

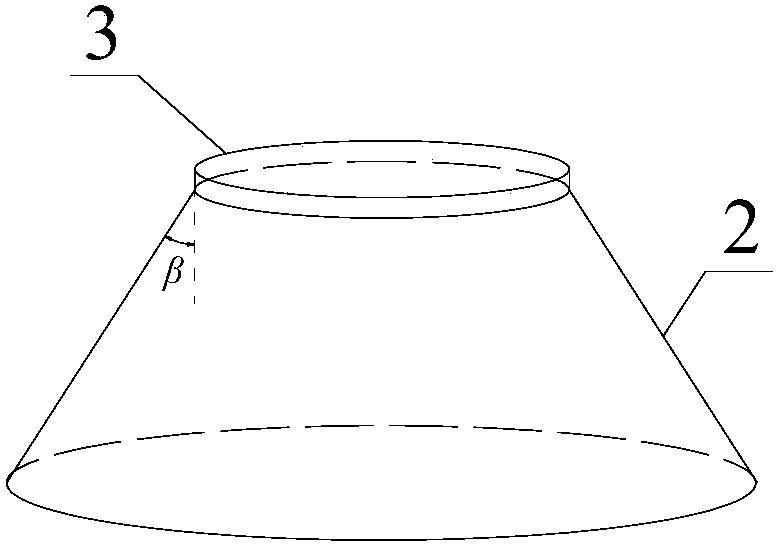

[0030] figure 2 It is a three-dimensional schematic diagram of the front sound wave booster. Weld the pre-acoustic booster on the emitting surface of the PZT piezoelectric ceramic disc. The encapsulation layer must completely enclose the front acoustic booster. The directivity of the ultrasonic wave is related to the half-diffusion angle of the sound source, and the half-diffusion angle θ is according to the formula obtained, where λ represents the wavelength and D represents the diameter of the piezoelectric element. When the included angle β between the front sound wave enhancer and the piezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com