Preparation method of alloy coating material

A technology of alloy cladding and cladding, which is applied in the field of preparation of alloy cladding materials, can solve problems such as material accumulation, precipitation, delamination, reducing the contact area between conductive substances and sulfuric acid, and affecting the electrical conductivity of cladding materials. Achieve good electrical conductivity, prevent deposition, and prevent deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1: Take 6g of polyacrylamide powder, add water to dissolve it, then add 40g of copper-zinc mixed powder, 10g of activated carbon powder, 4g of starch and 0.5g of glucose oxidase, and stir until it is evenly stirred to obtain mixed colloid 32.

[0036] Step two:

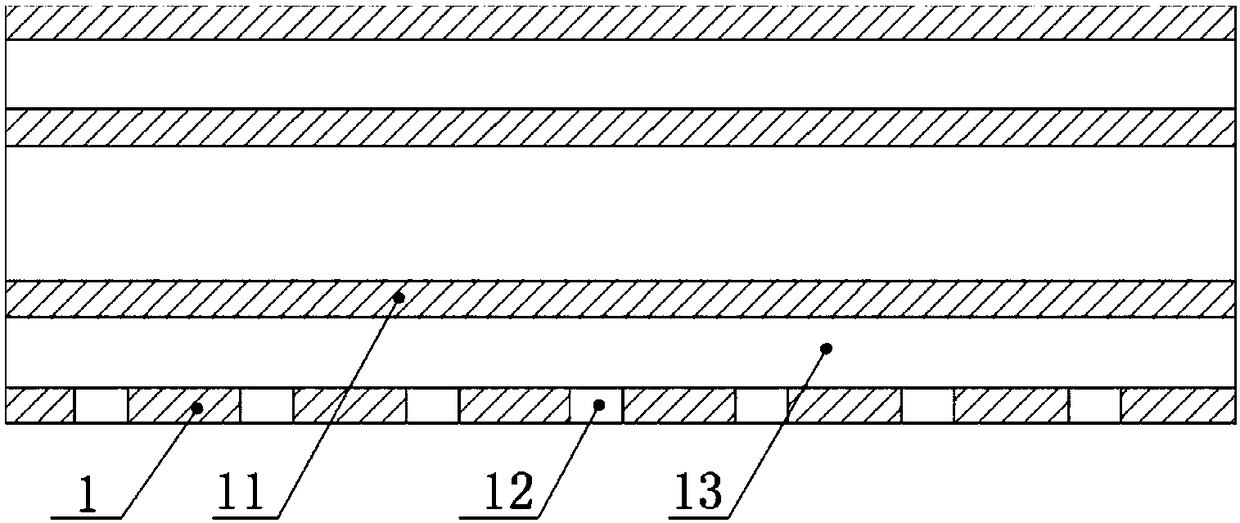

[0037] take as figure 1 As shown in the tubular first mold, the first mold includes a first inner shell 11 and a first outer shell 1, the first outer shell 1 is sleeved outside the first inner shell 11, and between the first inner shell 11 and the first outer shell 1 A first cavity 13 is formed, and a plurality of through holes 12 are opened on the first shell 1 , and the through holes 12 are arranged along the length direction of the first shell 1 .

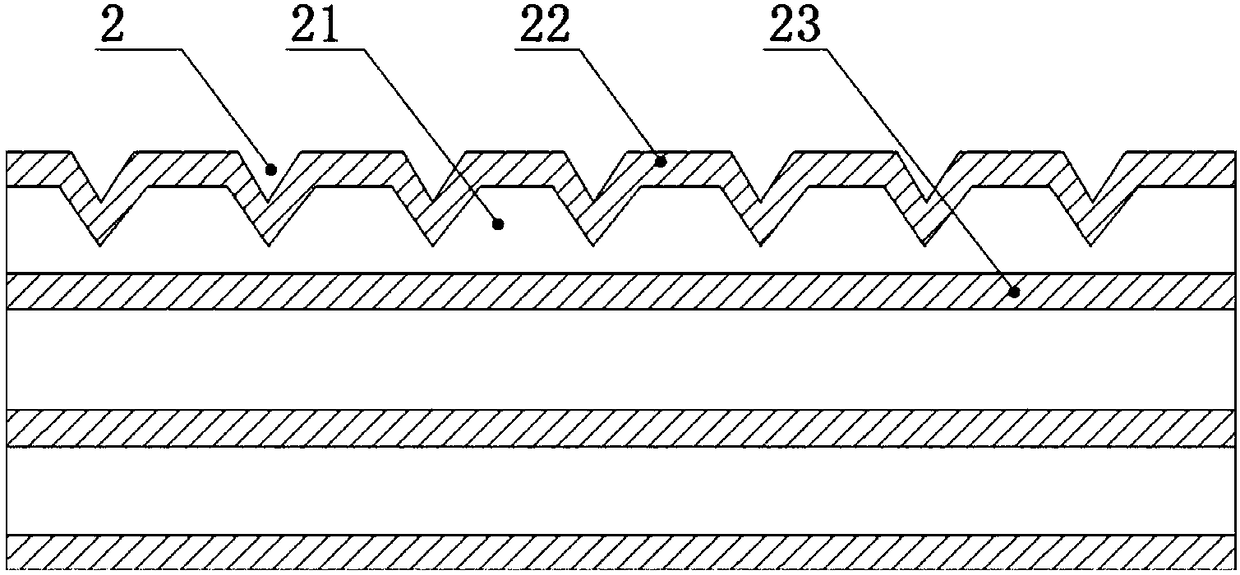

[0038] take as figure 2 The shown tubular second mold, the second mold includes a second inner shell 23 and a second outer shell 22, the second outer shell 22 is sleeved outside the second inner shell 23, between the second inner shell 23 and the second o...

Embodiment 2

[0048] The difference between this example and Example 1 lies in that the quality of each raw material is different, and the raw materials of corresponding quality are selected according to Table 1, and the production steps of Example 1 are repeated.

Embodiment 3

[0050] The difference between this embodiment and the foregoing embodiments lies in that the quality of each raw material is different, and the raw materials of corresponding quality are selected according to Table 1, and the manufacturing steps of Embodiment 1 are repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com