Device for preparing hypochloric acid for production of epoxide by chlorohydrin method and usage method thereof

An epoxide and preparation device technology, applied in the directions of hypochlorous acid, organic chemical methods, chemical instruments and methods, etc., can solve problems such as difficulty in meeting environmental protection emission standards, corrosion of production equipment, complex product composition, etc., and achieve environmental protection benefits. The effect of treatment and resource utilization, equipment corrosion mitigation, and simple wastewater composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

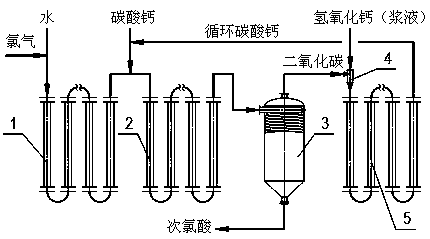

[0026] The hypochlorous acid preparation device used in the production of epoxides by the chlorohydrin method in Example 1 includes a hypochlorous acid reactor 1, a dehydrochlorination reactor 2, a gas-liquid separator 3, an injector 4, a carbon dioxide recovery reactor 5, and a connection between equipment Pipelines and intermediate tanks, material conveying devices, control and display instruments and accessories. The hypochlorous acid reactor 1 is provided with water and chlorine gas inlets; the outlet of the hypochlorous acid reactor 1 is connected with the inlet of the dehydrochlorination reactor 2 through a pipeline, and the connecting pipeline is provided with a calcium carbonate inlet; the gas-liquid separator 3 is provided with a material inlet, The liquid phase outlet and the gas phase outlet, the dehydrochlorination reactor 2 outlets are communicated with the material inlet of the gas-liquid separator 3 through a pipeline; the gas phase outlet of the gas-liquid separ...

Embodiment 2

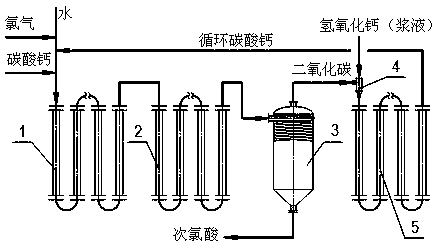

[0037] Embodiment 2 is substantially the same as Embodiment 1, except that calcium carbonate is added from the hypochlorous acid reactor 1 inlet.

[0038] The device diagram of embodiment 2 is shown in figure 2 .

Embodiment 3

[0040] Embodiment 3 is basically the same as Embodiment 1, except that the straight pipe part of hypochlorous acid reactor 1, dehydrochlorination reactor 2, and carbon dioxide recovery reactor 5 is a commercially available static mixer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com