A start-up method of ammonia compressor unit

A compressor unit and start-up method technology, applied in the preparation/separation of ammonia, chemical instruments and methods, ammonia compounds, etc., can solve the problems of increasing the start-up cost of ammonia compressor units, venting and reducing pressure at the compressor outlet, and high bearing temperature. Achieve the effects of controlling ammonia loss during start-up, zero back pressure start-up, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

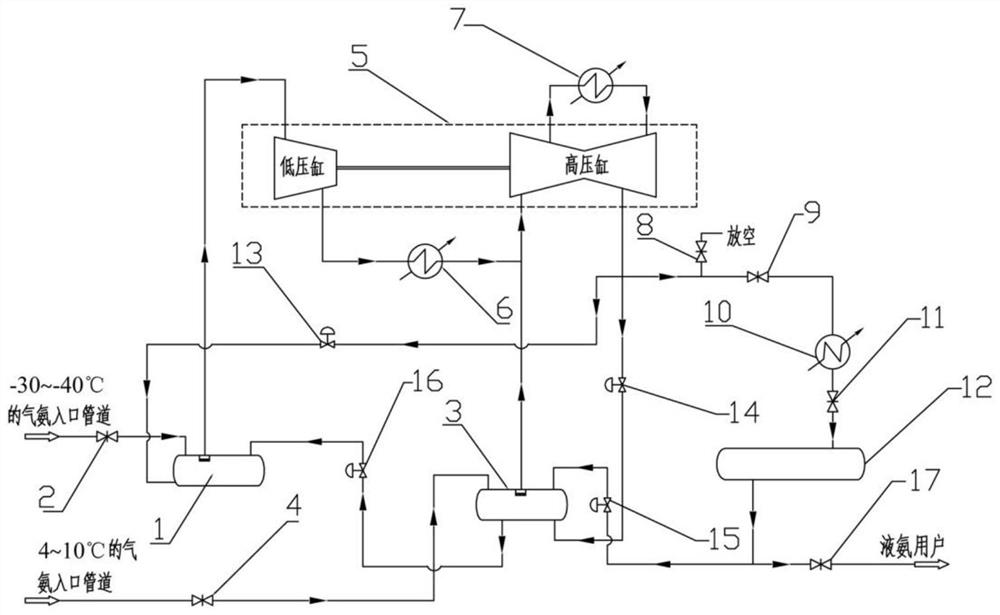

[0027] See attached figure 1 , a method for starting an ammonia compressor unit, specifically comprising the following steps:

[0028] (1) Before starting up, put the first-stage, second-stage and third-stage sealing gas into operation, perform dry gas sealing on the ammonia compressor unit, and then open the vent valve 8, first-stage anti-surge valve 13 and second-stage anti-surge valve 13 of the ammonia compressor unit working system. The section anti-surge valve 14 closes the three-section outlet valve 9, the ammonia storage tank inlet valve 11, the gas ammonia valve A, the gas ammonia valve B and the liquid ammonia valve 17 of the working system of the ammonia compressor unit;

[0029](2) feed nitrogen into the cylinder of the ammonia compressor 5, and replace the air in the cylinder until the oxygen content in the cylinder≤0.2%; then adjust the pressure of the dry gas seal primary and secondary seal gas, Make the pressure of the primary sealing gas 1.2-1.6MPaG, the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com