Dynamic polymer composition with hybrid structure and application thereof

A hybrid structure and polymer technology, applied in the field of intelligent polymers, can solve the problems of limited damping effect and fixed structure, and achieve the effects of wide range of uses, adjustable performance, high dynamic reversibility and stress sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

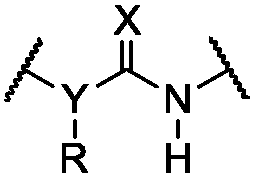

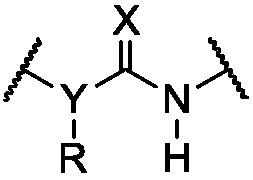

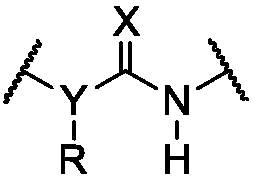

Image

Examples

preparation example Construction

[0082] In the preparation process of dynamic polymer foaming materials, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam dynamic polymers.

[0083] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the dynamic polymer to make it a uniform foam, and then through physical Or chemical changes make it gel and solidify to become a foam material. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0084] Wherein, the physical foaming method is to utilize physical principles to realize the foaming of the polymer in the preparation process of the dynamic polymer, and it generally includes the following five methods: (1) inert gas foaming method, that is, after adding Press the inert gas into the molten polymer or pasty ma...

Embodiment 1

[0150] (1) Vinyl acetic acid and 2,6-diaminopyridine were reacted in equimolar ratio to prepare compound 1.

[0151]

[0152] Mix 1.2 g of compound 1 and 3.5 g of bis(2-mercaptoethyl) adipate, add 0.5 wt% AIBN, and prepare a polymer containing a general covalent crosslinking network by click reaction.

[0153] (2) Mix 5.0g of 1,11-dichloro-1,1,3,3,5,5,7,7,9,9,11,11-dodecamethylhexasiloxane and 1.2g of boric acid, Heating to 80° C., then adding a small amount of water and 6.3 mg of graphene powder, and continuing the reaction for 8 hours to obtain a cross-linked dynamic polymer containing silicon borate bonds. Composite the cross-linked polymer containing silicon borate bonds with the above-mentioned polymer containing ordinary covalent cross-linking networks to obtain a dynamic polymer containing ordinary covalent cross-links and silicon borate bonds.

[0154] The polymer product can be used as an energy-absorbing cushioning material and applied to cushioning packaging mat...

Embodiment 2

[0156] (1) Reaction of ethyl acrylate-2-isocyanate and mercaptoethyl acrylate to prepare compound 2.

[0157]

[0158] 1,3-diphenylpropane-2,2-dithiol, compound 2 and triallylamine were mixed according to the molar ratio of 9:6:2, and placed in an ultraviolet crosslinking apparatus for 8 hours of ultraviolet radiation to obtain a compound containing common A covalently cross-linked polymer as the first network polymer.

[0159] (2) Mix 20g of hydroxyl-terminated methyl-3,3,3-trifluoropropyl polysiloxane (molecular weight is about 12000) and 3.2g of diphenyl borohydrogenate, heat up to 80°C and stir evenly, 4ml of deionized water was added, and the polymerization reaction was carried out under stirring to prepare a cross-linked dynamic polymer containing silicon borate bonds. Composite the cross-linked polymer containing silicon borate bonds in the above-mentioned first network polymer to obtain a dynamic polymer containing ordinary covalent cross-links and silicon borate b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com