Scale inhibitor for S-Zorb device, preparation method and application thereof

A technology of anti-scaling agent and application method, which is applied in the direction of treatment equipment corrosion/scaling inhibition, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems such as short application time, and achieve the goals of reducing energy consumption, adding a small amount, and inhibiting coking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

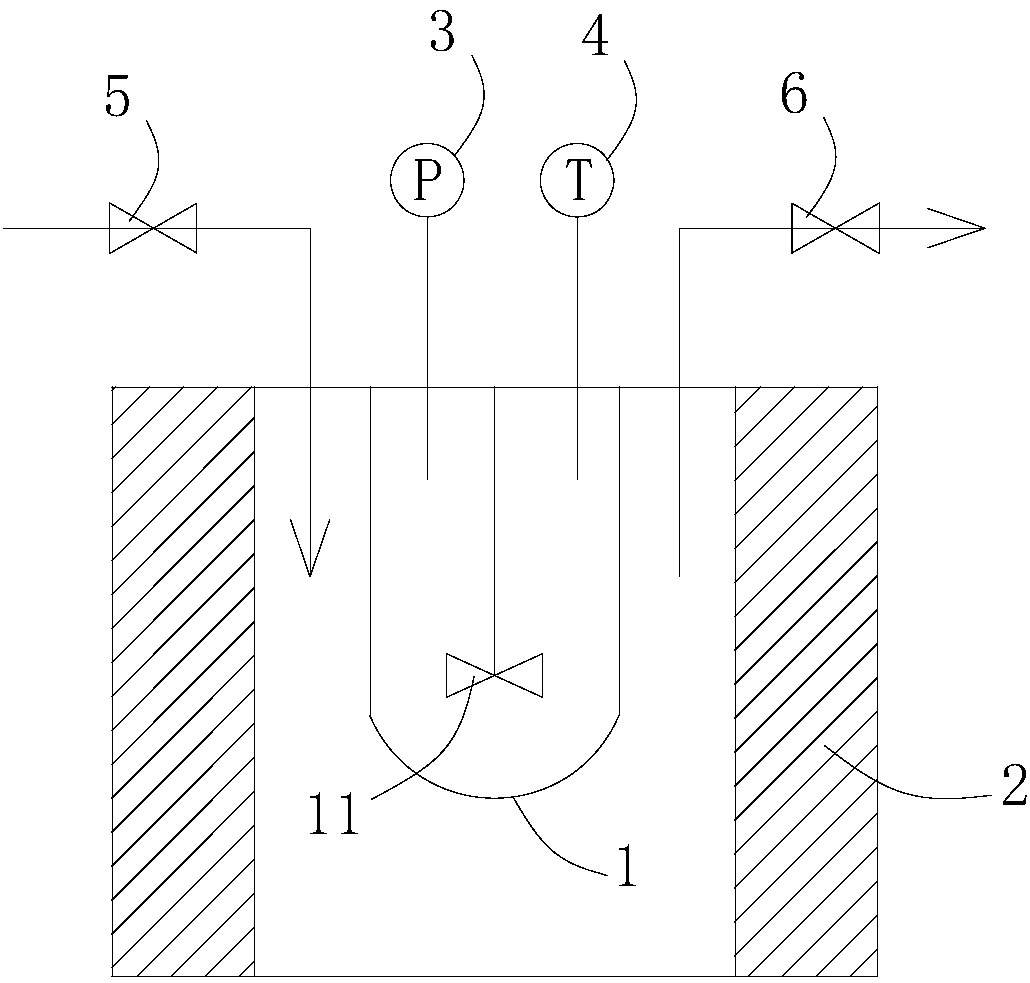

Method used

Image

Examples

Embodiment 1

[0061] Take 10g of polyisobutylene Mannich base, 10g of 4-hydroxy-2,2,6,6-tetramethylpiperidine nitroxide radical, 10g of 2,5-di-tert-butylhydroquinone and S-1000 # 70g of aromatic solvent oil, mixed and stirred uniformly in a reaction kettle under normal temperature and pressure.

[0062] See Table 1 and Table 2 for measuring the nitrogen content and metal ion content of the scale inhibitor obtained in this implementation.

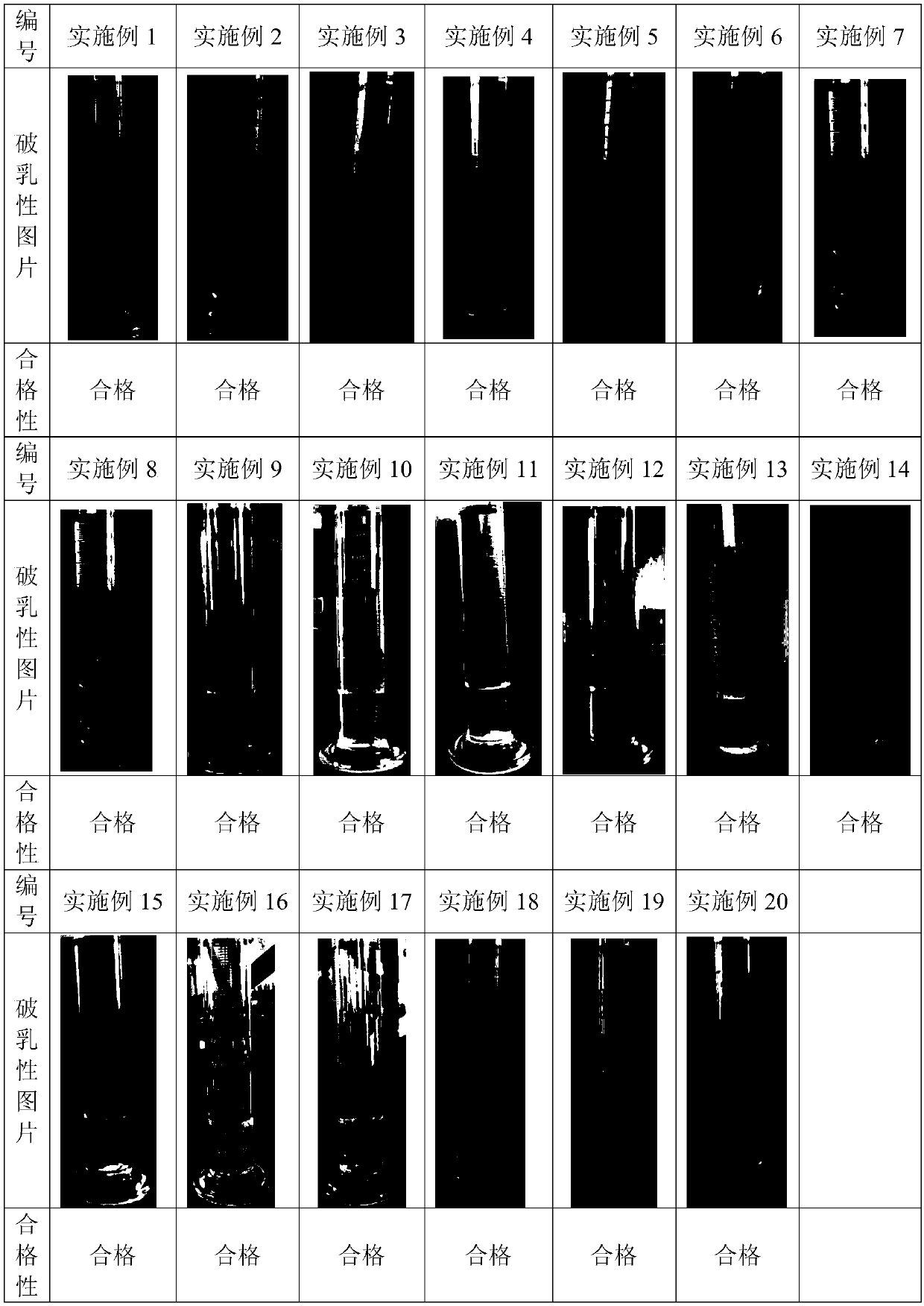

[0063] The antiscalants obtained in this example were added to catalytically cracked gasoline at the addition amount of 100ppm, 150ppm and 200ppm respectively, and the antiscalant performance, dispersion performance and emulsification performance were measured, see figure 2 , Table 3, Table 4 and image 3 .

Embodiment 2

[0065] Take 15g of polyisobutylene Mannich base, 10g of 4-hydroxy-2,2,6,6-tetramethylpiperidine nitroxide radical, 8g of 2,5-di-tert-butylhydroquinone and S-1000 # 67g of aromatic solvent oil, mixed and stirred evenly under normal temperature and pressure in a reaction kettle.

[0066] See Table 1 and Table 2 for measuring the nitrogen content and metal ion content of the scale inhibitor obtained in this implementation.

[0067] Add the antiscalant obtained in this example to catalytic cracking gasoline at the addition amount of 100ppm, 150ppm and 200ppm respectively, and measure its antiscalant performance, dispersion performance and emulsification performance, see Table 3, Table 4 and image 3 .

Embodiment 3

[0069] Take 20g of polyisobutylene Mannich base, 1g of 1,1-diphenyl-2-trinitrophenylhydrazine, 6g of 4-hydroxyl-2,2,6,6-tetramethylpiperidine nitroxide free radical, 2 , 5-di-tert-butylhydroquinone 6g, p-tert-butylcatechol 2g and S-1500 # 65g of aromatic solvent oil, mixed and stirred evenly under normal temperature and pressure in a reaction kettle.

[0070] See Table 1 and Table 2 for measuring the nitrogen content and metal ion content of the scale inhibitor obtained in this implementation.

[0071] Add the antiscalant obtained in this example to catalytic cracking gasoline at the addition amount of 100ppm, 150ppm and 200ppm respectively, and measure its antiscalant performance, dispersion performance and emulsification performance, see Table 3, Table 4 and image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com