Laser-induced breakdown spectroscopy quick detecting method based on multi-spectral inner calibration

A technology of laser-induced breakdown and detection methods, which is applied in the directions of measuring devices, thermal excitation analysis, material excitation analysis, etc., can solve the problem of affecting the sample ablation amount, plasma spectral intensity, violation of in-situ analysis and online analysis, and inability to unify samples Pretreatment and other issues to achieve the effect of improving detection accuracy, reducing errors, and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] Through the verification process in the following examples, it is verified that the technical solution of the present application can greatly improve the detection accuracy of LIBS without sample pretreatment, as follows:

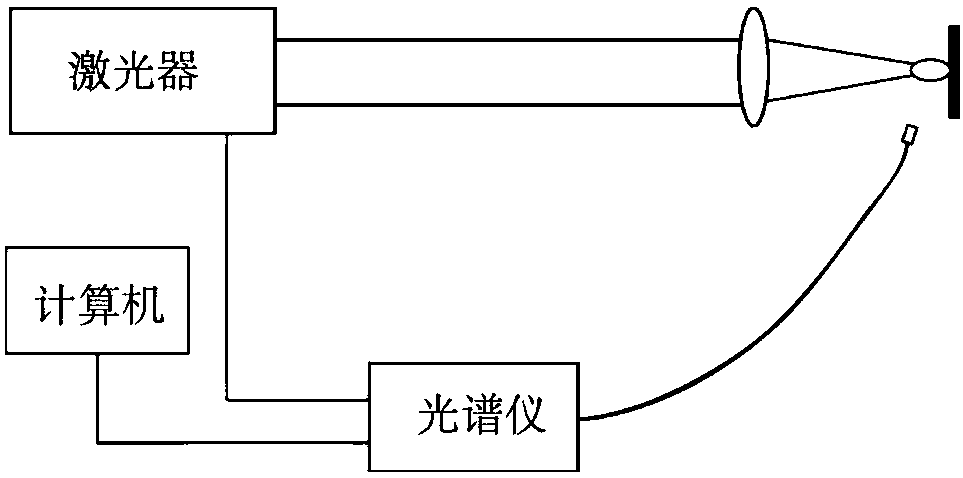

[0027] (1) if figure 1 As shown, the LIBS detection experimental device and platform were built, including pulsed lasers, spectrometers, computers, several optical components, and electric translation stages. Of course, a commercially available laser-induced breakdown spectrometer can also be directly purchased for detection during LIBS detection.

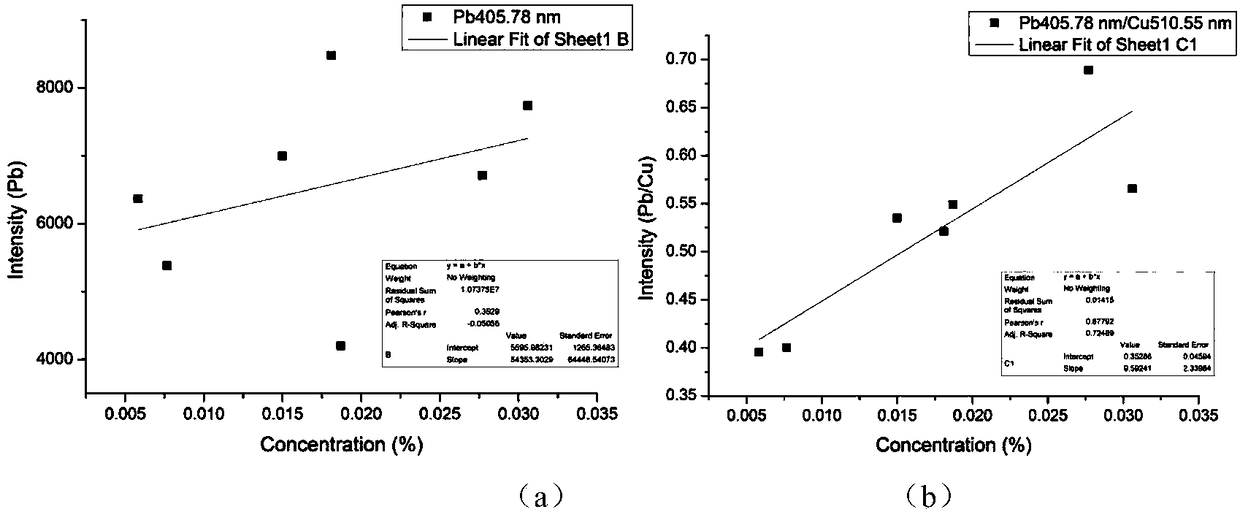

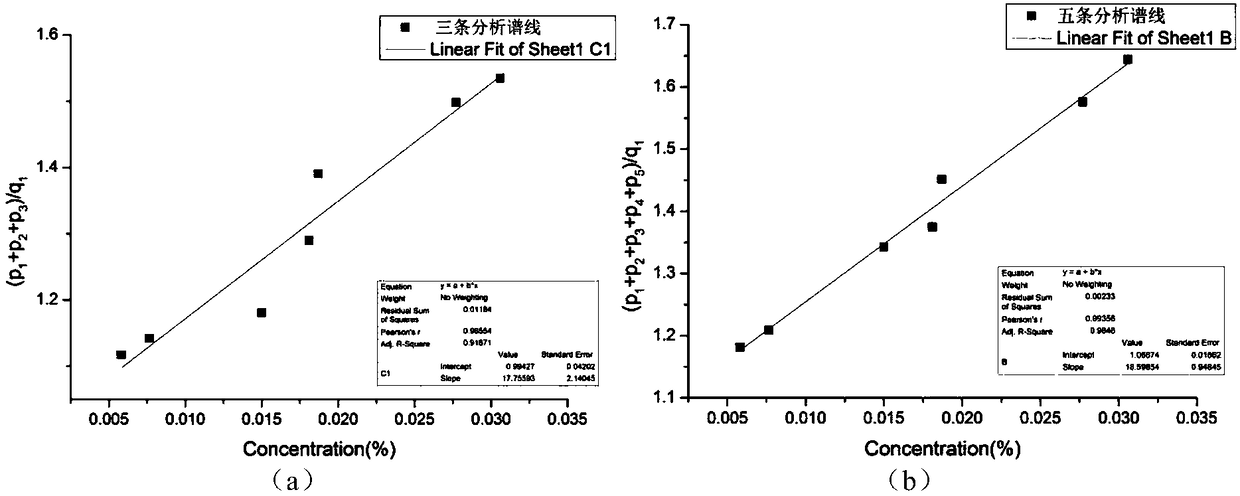

[0028] (2) Select some samples with irregular surface. For clarity of expression, a set of copper alloy samples (7 pieces in total) are selected as examples in this embodiment. The range of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com