Bovine-molar geometric-feature-based biomimetic design method of colloid-mill grinding head

A technology of geometric features and design methods, applied in computer-aided design, geometric CAD, design optimization/simulation, etc., can solve the problems of reduced refinement effect, easy wear, large flow change, etc., and achieve obvious optimization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

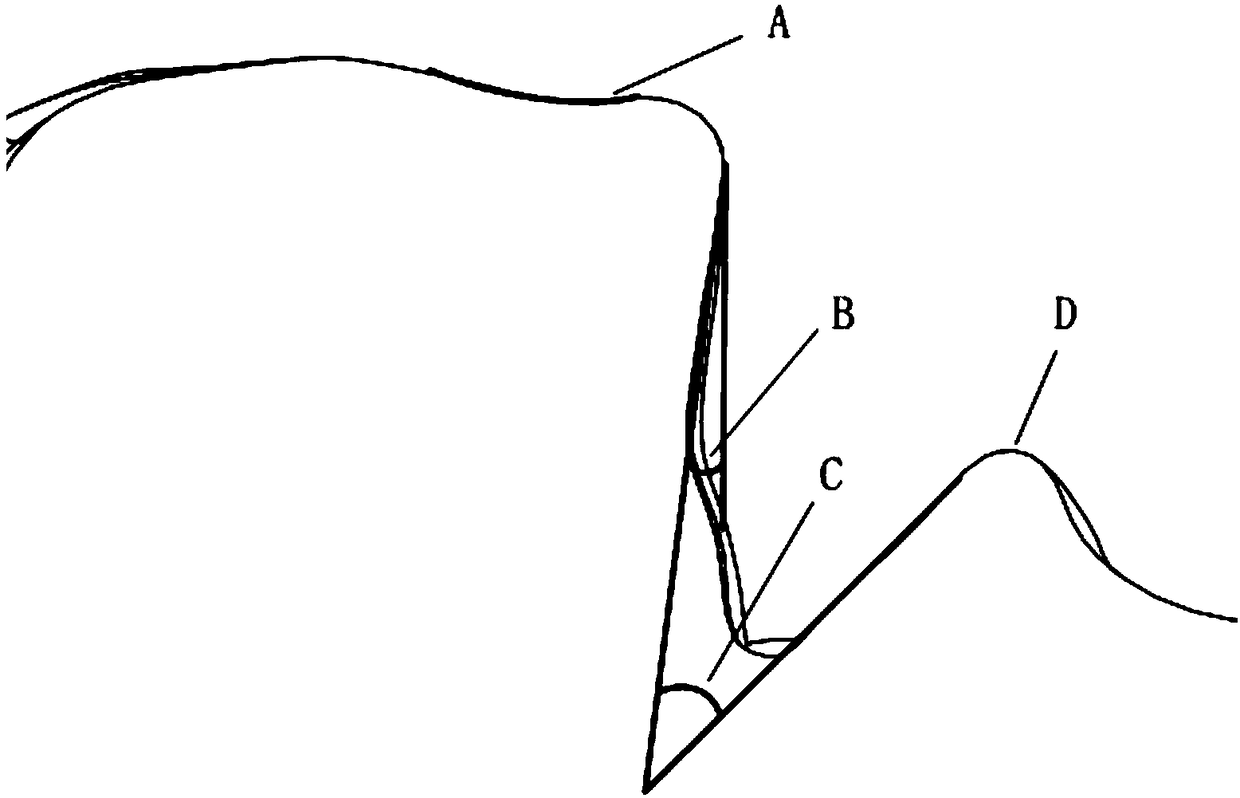

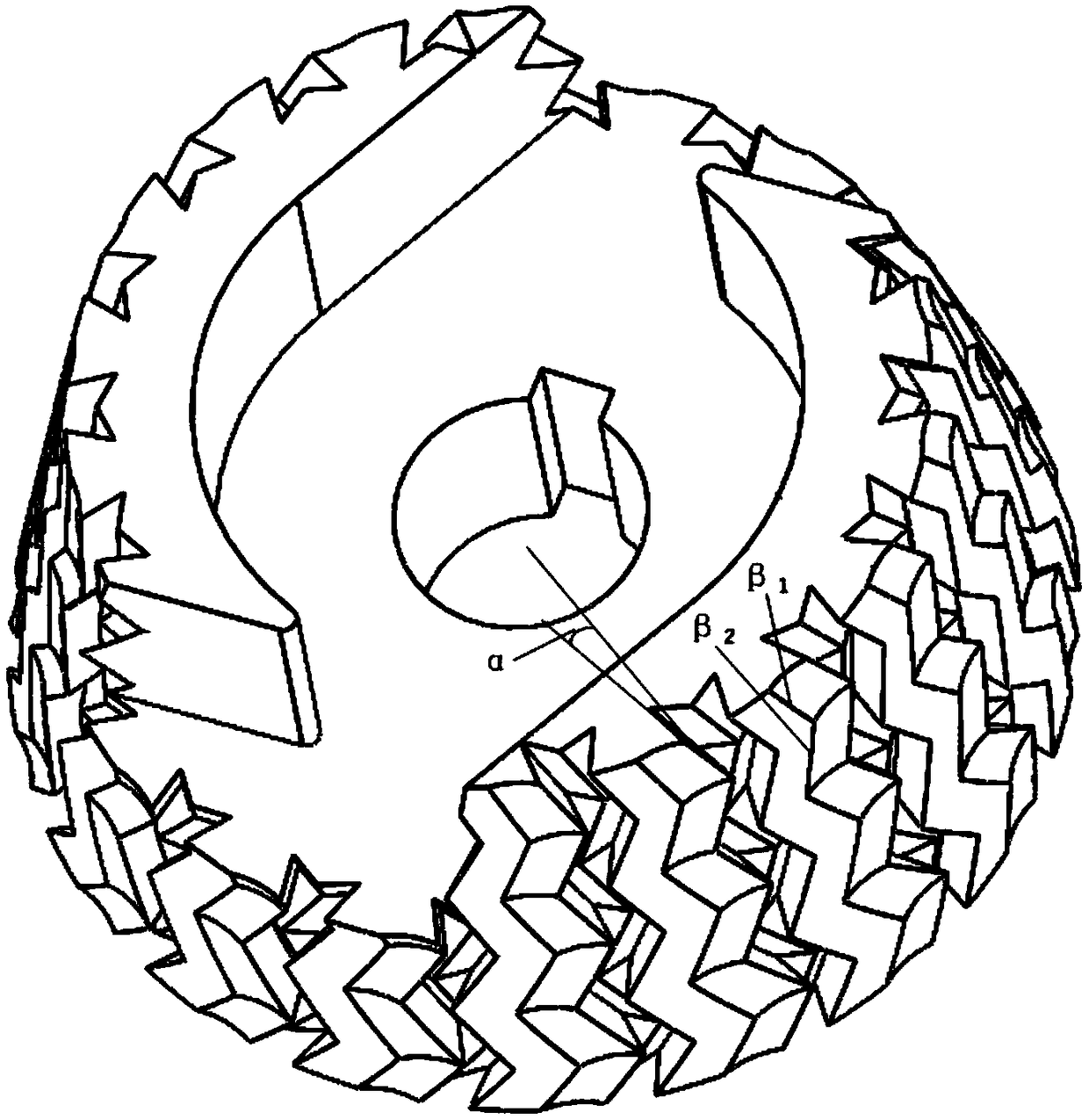

[0031] like figure 1 and figure 2 As shown, a kind of colloid mill grinding head bionic design method based on bovine molar geometric feature provided by the invention comprises the following steps:

[0032] S1. Obtain the point cloud data of the complete bovine molar surface.

[0033] In this embodiment, a high-precision three-dimensional scanner is used to perform three-dimensional scanning on mature and complete bovine molars to obtain point cloud data of the complete molar surface. The point cloud data of the complete bovine molar surface is obtained by scanning the complete permanent dentition of mature cattle with a growth time of more than four years. The crown characteristics of the permanent dentition of mature cattle are relatively complete, which makes the data required for bionics more accurate.

[0034] S2. Preprocessing a large amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com