Dual-stator hybrid permanent-magnet memory motor

A hybrid permanent magnet and memory motor technology, applied in the direction of magnetic circuits, electrical components, electromechanical devices, etc., can solve the problems of increasing winding capacity, reducing mechanical reliability, and difficulty in adjustment, so as to ensure power density, change operating range and Efficiency, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

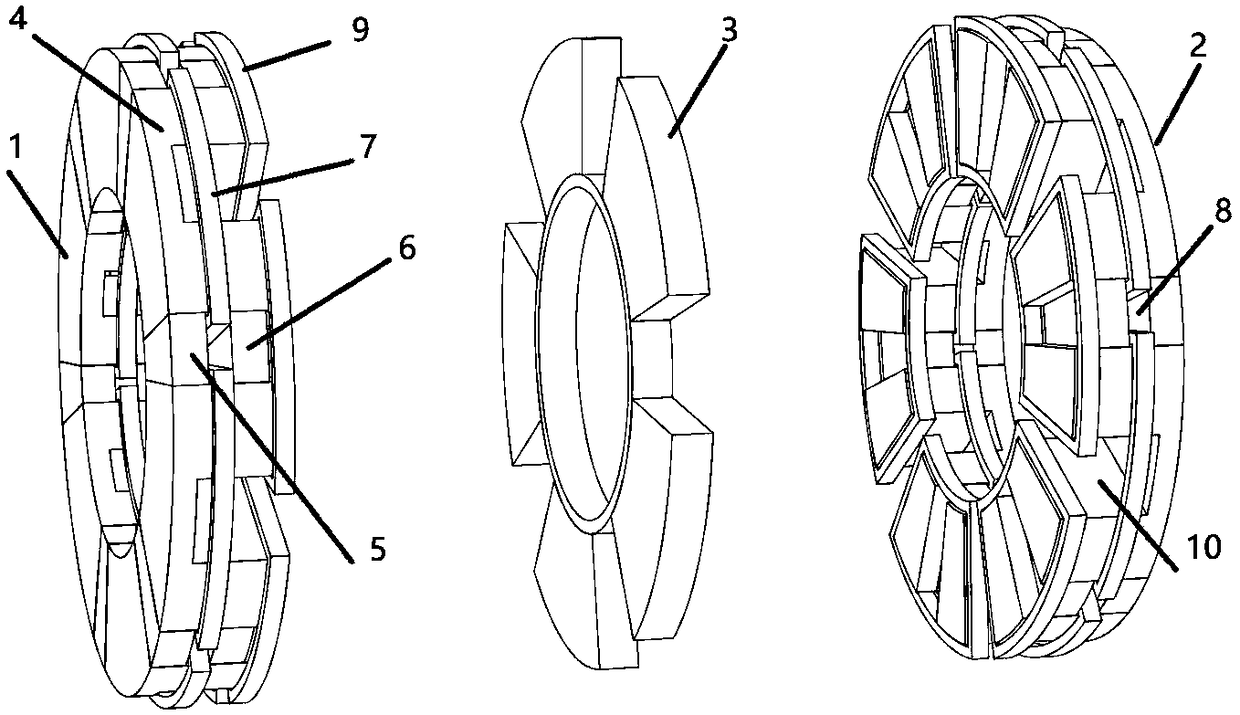

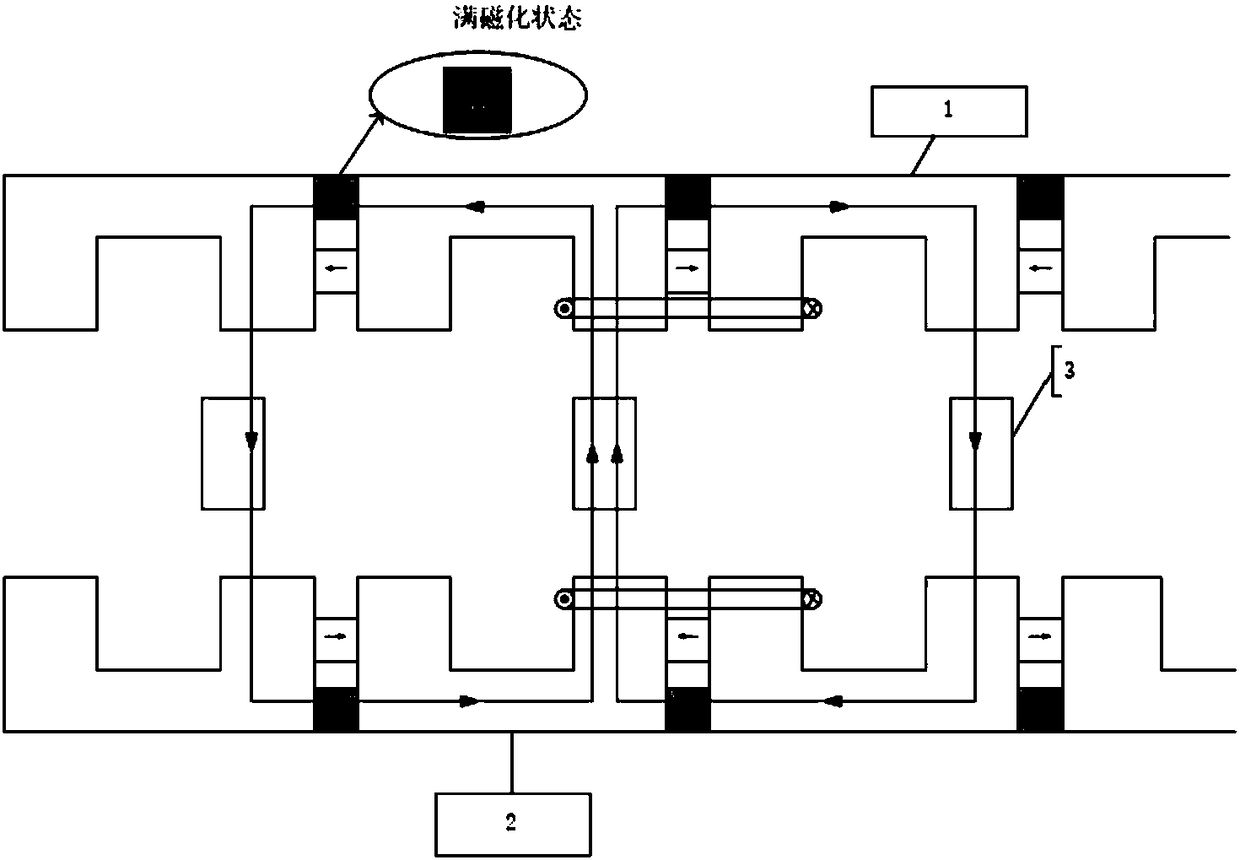

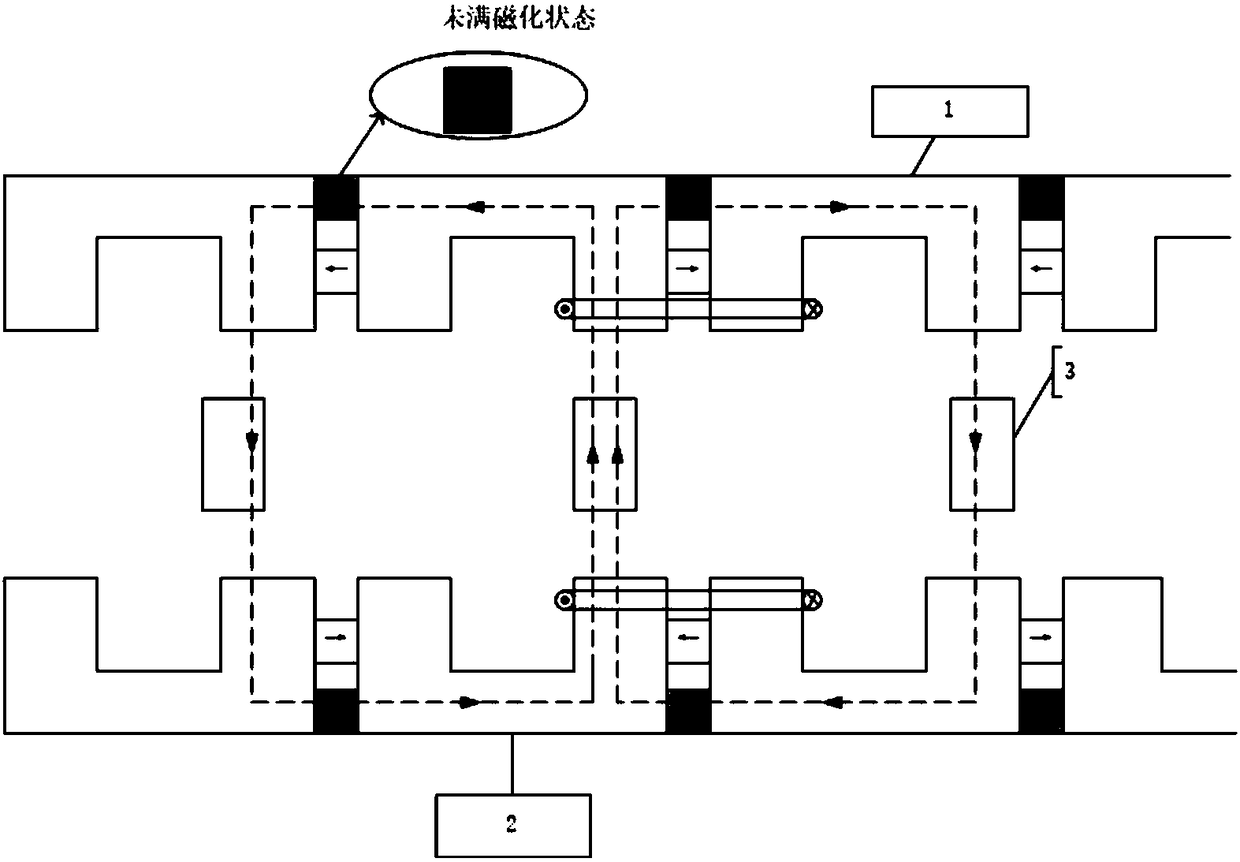

[0021] Such as figure 1 As shown, the dual-stator hybrid permanent magnet memory motor of the present invention includes a first stator 1, a second stator 2 and a rotor 3, and the first stator 1, the second stator 2 and the rotor 3 all adopt a salient pole structure, The two stators have the same structure and are opposite to each other. The rotor is in the middle of the two stators and installed coaxially. The material of the installation shaft is non-magnetic material. The stator includes a stator core, AlNiCo permanent magnets, NdFeB permanent magnets, armature windings, and magnetic modulation windings; both the rotor and the stator core are made of silicon steel sheets of magnetically permeable materials.

[0022] The stator core is a circular shape surrounded by 6n U-shaped cores 4. The opening of the U-shaped cores 4 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com