Equal pole double-section reluctance generator

A reluctance generator and equipolar technology, applied in electrical components, electromechanical devices, DC commutators, etc., can solve the problems of large resonance noise of magnetic poles, large starting resistance of power generation, and imperfect effects, etc., so as to improve the output voltage , outstanding performance and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

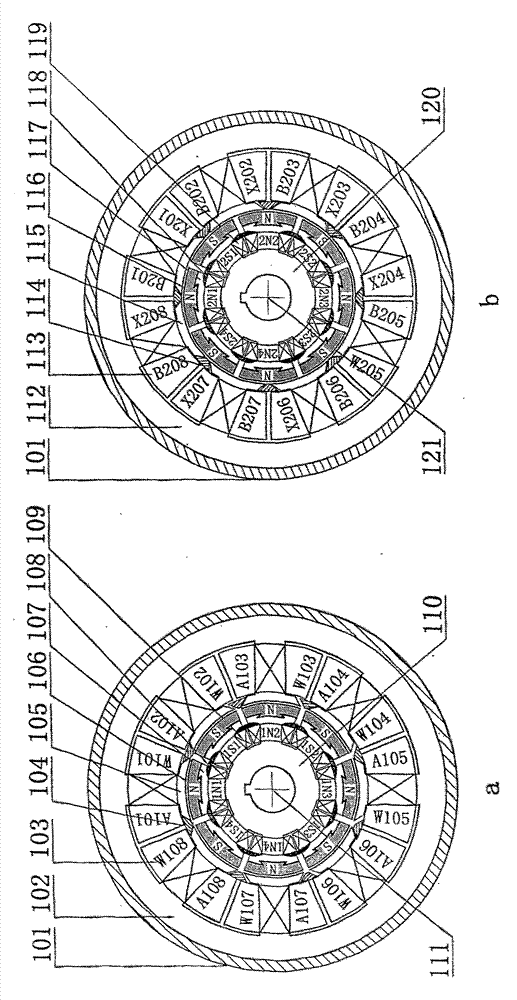

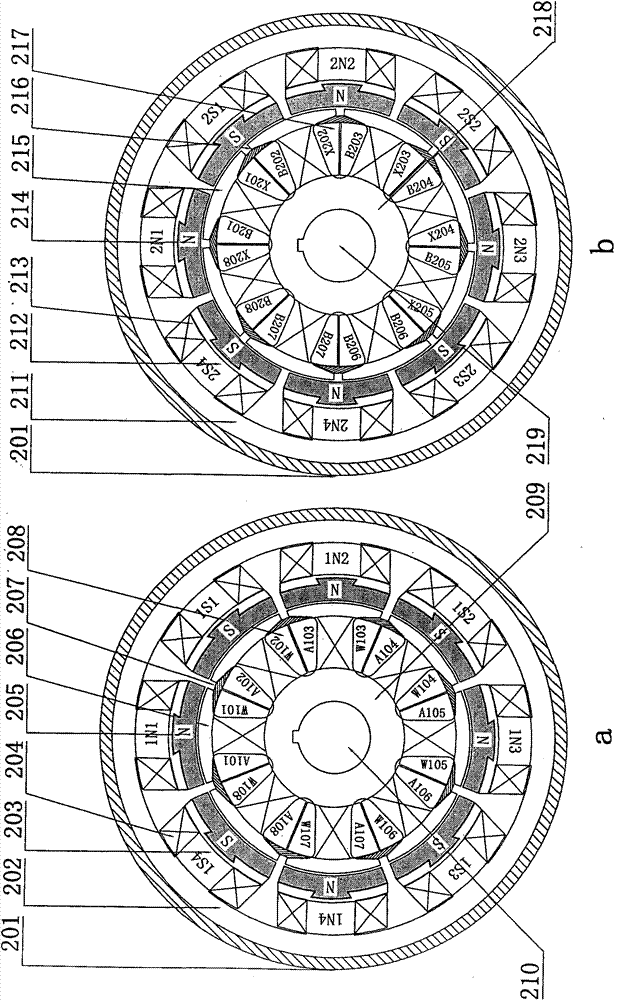

[0052] A permanent-magnet surface-mounted electric excitation magnetic pole inner-rotor double-segment generator, including a two-segment stator and a rotor (such as figure 1 , Figure 7 shown), the stator includes a motor casing 101, a first section of stator core yoke 102, a second section of stator core yoke 112, a first section of stator armature winding 103, a second section of stator armature winding 113, a second section of stator armature winding 113, a A section of stator wedge 104, a second section of stator wedge 114, a first section of stator pole 105, a second section of stator pole 115 and a motor base 137; the rotor includes the first section of rotor permanent magnet surface-mounted electric excitation pole 106, The second section of rotor permanent magnet surface mount electric excitation pole 116, the first section of rotor electric excitation pole 107, the second section of rotor electric excitation pole 117, the first section of rotor slot wedge 108, the se...

Embodiment 2

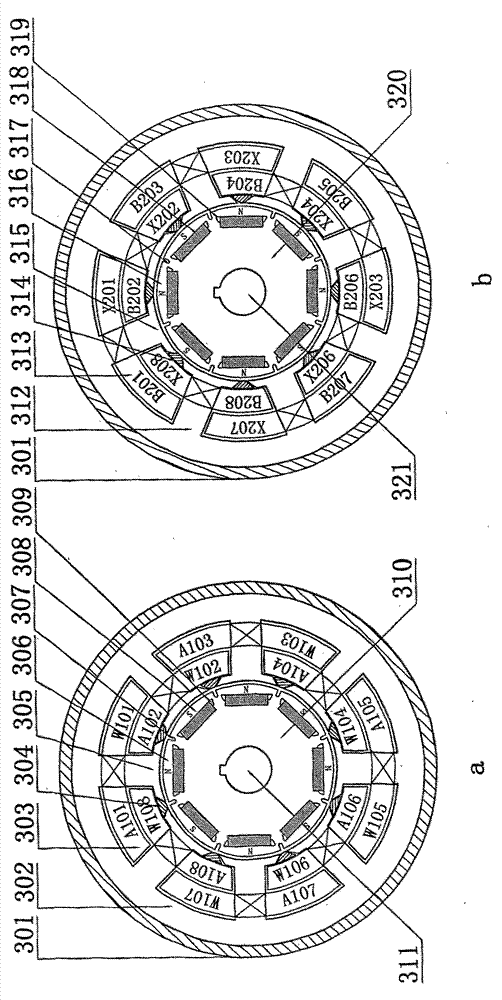

[0062] A radial inner rotor double-stage generator with built-in permanent magnets, including a two-stage stator and a rotor (such as image 3 , Figure 9 shown), the stator includes a motor housing 301, a first section of stator core yoke 302, a second section of stator core yoke 312, a first section of stator armature winding 303, a second section of stator armature winding 313, a second section of stator armature winding 313, a A section of stator wedge 304, a second section of stator wedge 314, a first section of stator pole 305, a second section of stator pole 315 and a motor base 337; the rotor includes the first section of rotor permanent magnet built-in radial pole 306, the second The radial magnetic poles 316 inside the permanent magnets of the second section of the rotor, the magnetic separation slots 307 of the first section of the rotor, the magnetic separation slots 317 of the second section of the rotor, the radial permanent magnets 308 inside the permanent magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com