Bonding composition

A technology of composition and viscosity, which is applied in the direction of assembling printed circuits with electrical components, inorganic adhesives, adhesive additives, etc., can solve the problems of not considering the formation of solder joints, hindering LED light emission, and difficult luminous intensity, etc., to achieve dispersion Excellent performance, suppression of solder joint formation, and improvement of dispersion state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0152] 400 ml of toluene (a first-grade reagent manufactured by Wako Pure Chemical Industries, Ltd.) and 30 g of hexylamine (a first-grade reagent manufactured by Wako Pure Chemical Industries, Ltd.) were mixed and sufficiently stirred with a magnetic stirrer. Here, 10 g of silver nitrate (reagent special grade manufactured by Toyo Chemical Industry Co., Ltd.) was added while stirring, and after the silver nitrate was dissolved, 10 g of oleic acid (reagent grade manufactured by Wako Pure Chemical Industries Co., Ltd.) was added. . Here, a 0.01 g / ml aqueous sodium borohydride solution prepared by adding 1 g of sodium borohydride (manufactured by Wako Pure Chemical Industries, Ltd.) to 100 ml of ion-exchanged water was added dropwise to obtain a liquid containing silver microparticles.

[0153] After stirring for 1 hour, 300 ml of methanol (special grade reagent manufactured by Wako Pure Chemical Industries, Ltd.) was added to aggregate and settle the silver fine particles. Fur...

Embodiment 2

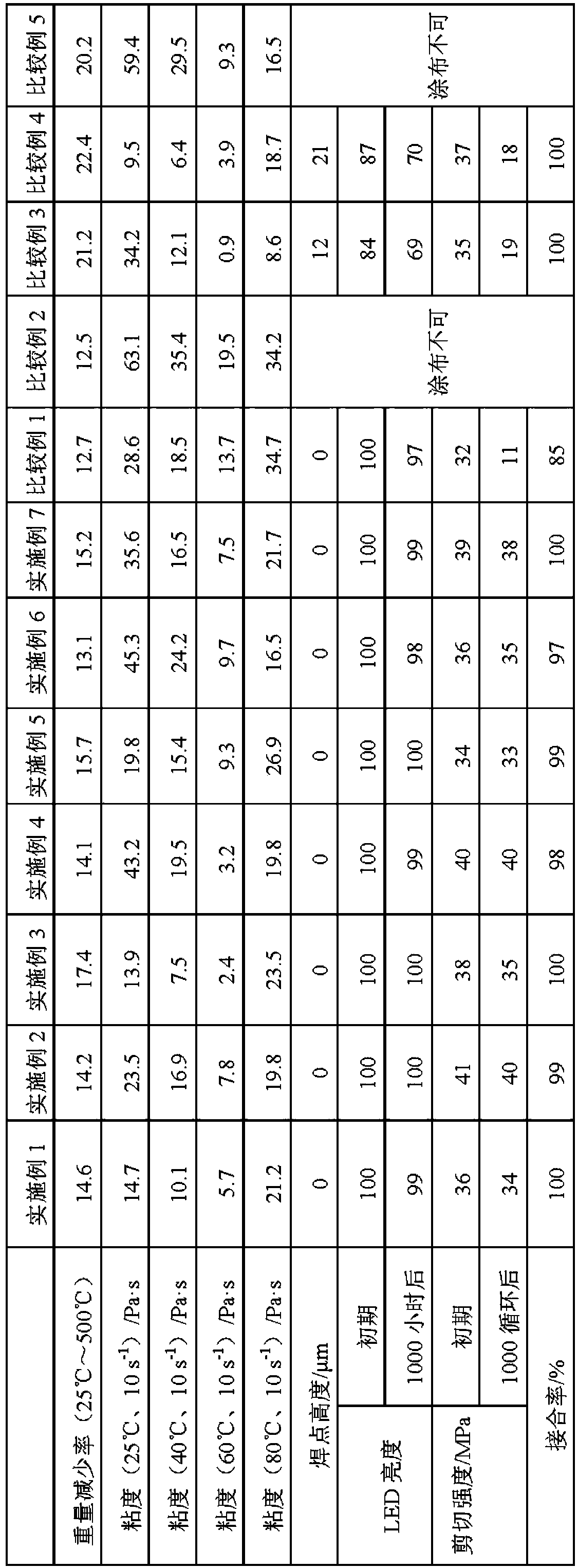

[0170] Composition 2 for joining was obtained in the same manner as in Example 1 except that the addition amount of oleic acid was 7 g. Various characteristics were evaluated in the same manner as in Example 1, and the obtained results are shown in Table 1.

Embodiment 3

[0172] Composition 3 for joining was obtained in the same manner as in Example 1 except that the addition amount of oleic acid was 15 g. Various characteristics were evaluated in the same manner as in Example 1, and the obtained results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com