Superabsorbent resin and method for producing same

A superabsorbent and polymer technology, applied in the field of superabsorbent polymers and their preparation, can solve the problems of reduced basic absorption capacity, reduced liquid permeability, insufficient liquid permeability and gel strength of superabsorbent polymers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

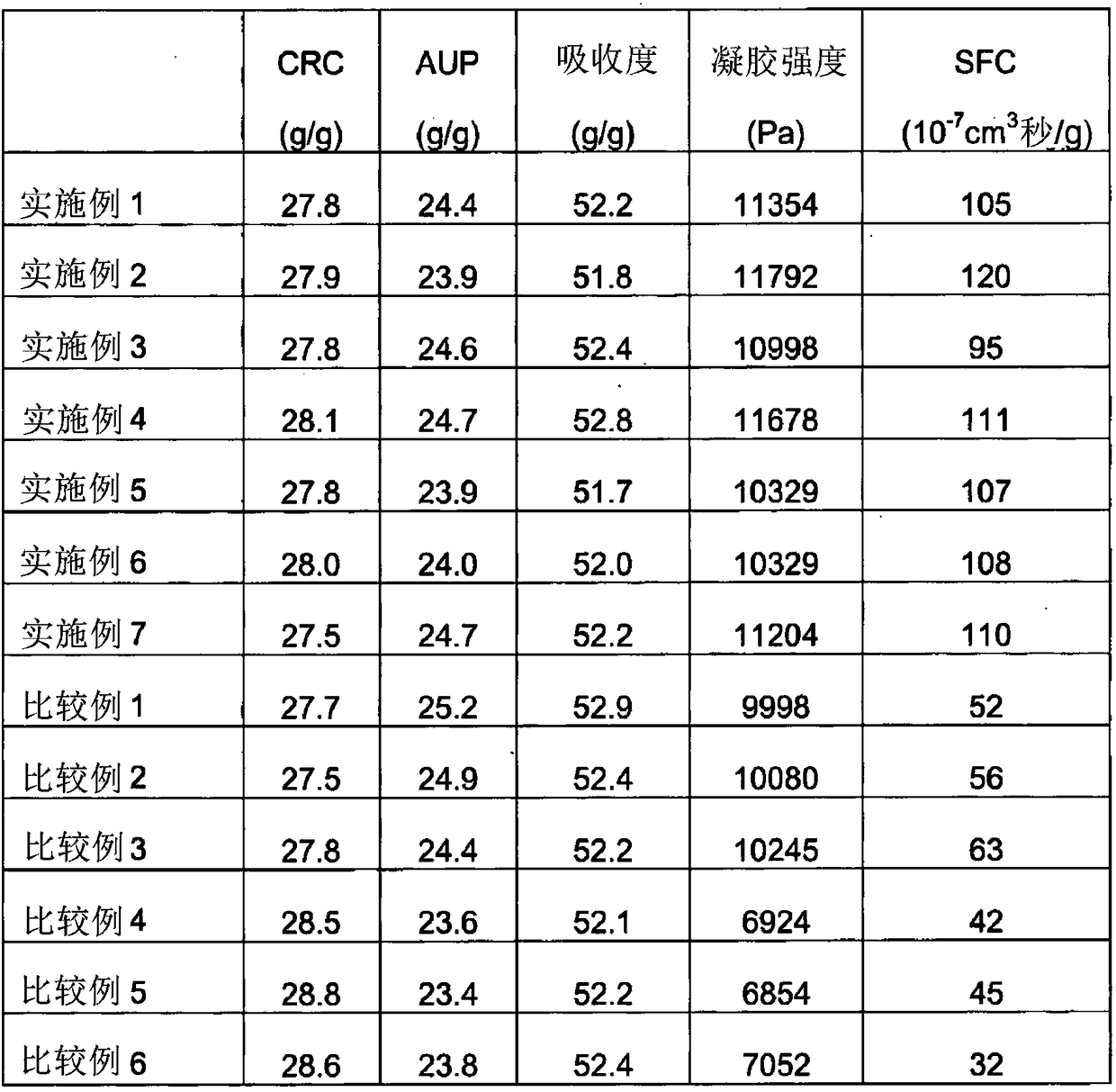

Embodiment 1

[0179]500 g of acrylic acid and 3 g of polyethylene glycol diacrylate (Mw=523) were added and mixed. Then, 0.01 g of diphenyl(2,4,6-trimethylbenzoyl)-phosphine oxide was added and dissolved. Then, 896.4 g of a 24.5% by weight aqueous sodium hydroxide solution was added, and nitrogen gas was continuously added to prepare a water-soluble unsaturated monomer aqueous solution. Then, the temperature of the aqueous solution was cooled to 50° C., and the aqueous solution was irradiated with ultraviolet rays for 90 seconds to obtain a hydrogel-like polymer. The obtained hydrogel polymer was pulverized using a pulverizing device. Classification was performed with standard sieves according to ASTM standards to prepare base polymer powders with a particle size of 150 μm to 710 μm. The gel strength of the base polymer powder was measured to be 6588 Pa.

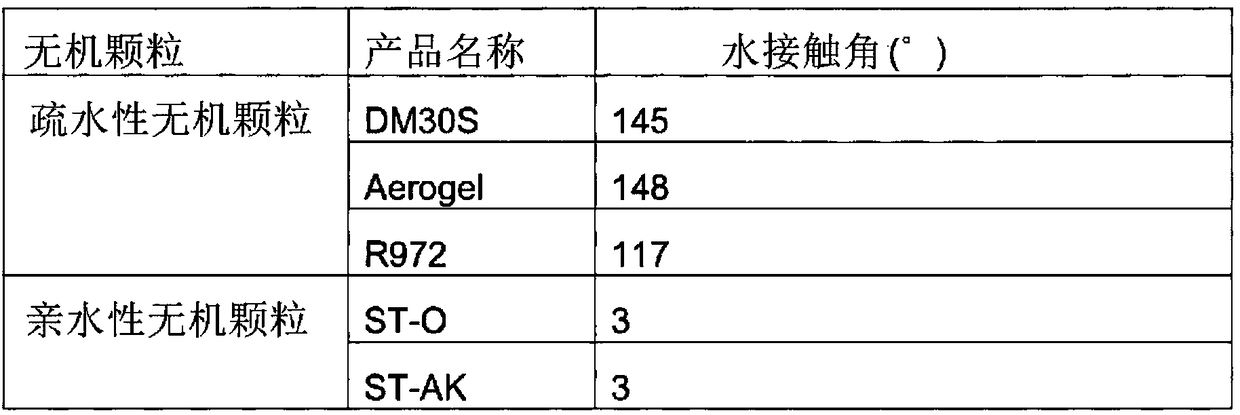

[0180] Then, 0.05 parts by weight of hydrophobic silica particles (DM30S) was added to 100 parts by weight of the prepared base polym...

Embodiment 2

[0183] The superabsorbent polymer of Example 2 was prepared according to the same method and surface crosslinking conditions as in Example 1, except that for the base polymer powder (gel strength: 6588 Pa), 0.05 parts by weight of Aerogel was added instead of the hydrophobic Silica particles DM30S.

[0184] After the above surface cross-linking step, classification was carried out with a standard sieve according to ASTM standards to obtain the polymer powder of Example 2 with a particle size of 150 μm to 710 μm.

Embodiment 3

[0186] The superabsorbent polymer of Example 3 was prepared according to the same method and surface crosslinking conditions as in Example 1, except that for the base polymer powder (gel strength: 6588 Pa), 0.05 parts by weight of R972 was added instead of hydrophobic Silica particles DM30S.

[0187] After the above-mentioned surface crosslinking step, classification was carried out with a standard sieve according to ASTM standards to obtain the polymer powder of Example 3 with a particle size of 150 μm to 710 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com