Highly-fragrant flavored fermented milk and preparation method thereof

A fermented milk, inoculation and fermentation technology, applied in dairy products, milk preparations, applications, etc., can solve problems affecting the effect of aroma production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0142] 1. Raw material formula:

[0143] Concentrated skimmed milk 69.786%, sucrose 8.2%, cream 6.0%, fermented cream 16.0%, fermented bacteria (combined bacterial agents containing Lactobacillus bulgaricus, Streptococcus thermophilus and Bifidobacterium lactis, purchased from Danisco (China) Investment Limited) 0.014%. Said percentage is the mass ratio of each component relative to the flavored fermented milk final product.

[0144] The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0145] Two, produce the product of the present embodiment according to following process method:

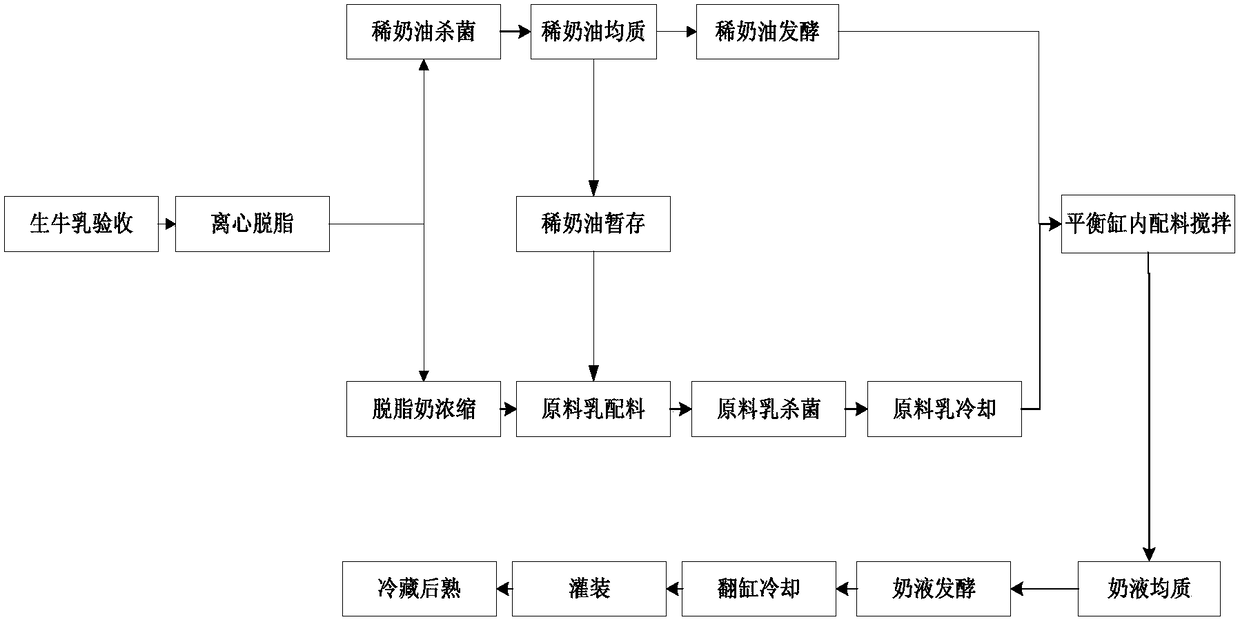

[0146] see figure 1 Shown, the technological process of the product of the present embodiment mainly comprises:

[0147] Acceptance of raw milk: Acceptance according to the standard requirements of GB19301.

[0148] Centrifugal degreasing: Use an online degreasing separator, the operating temperature is 50°C to 55°C, and the f...

Embodiment 2

[0163] 1. Raw material formula:

[0164] Skimmed milk 76.68%, sucrose 7.5%, concentrated milk protein powder 4.3%, fermented cream 6.5%, cream 5.0%, fermented bacteria (including Lactobacillus bulgaricus and Streptococcus thermophilus, purchased from Danisco (China) Investment Co., Ltd. )0.02%. Said percentage is the mass ratio of each component relative to the flavored fermented milk.

[0165] The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0166] Two, produce the product of the present embodiment according to following process method:

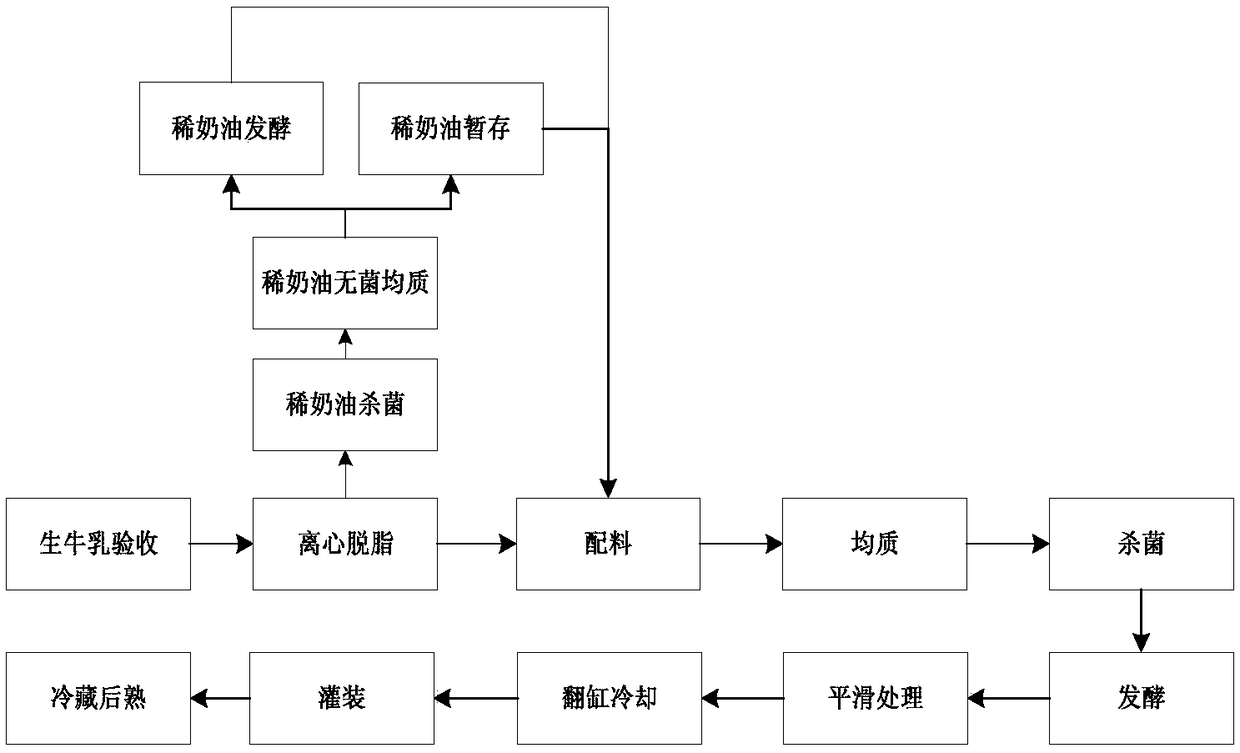

[0167] 1. Process flow:

[0168] See the process flow figure 2 .

[0169] 2. Process description:

[0170] 2.1 Acceptance of raw milk: acceptance according to the standard requirements of GB19301.

[0171] 2.2 Centrifugal degreasing: Use an online degreasing separator with an operating temperature of 50°C to 55°C. The fat content of export cream is 35%. The fat...

Embodiment 3

[0186] 1. Raw material formula:

[0187] Concentrated skimmed milk 69.786%, sucrose 8.2%, cream 16.0%, fermented cream 6.0%, fermented bacteria (combined microbial agent containing Lactobacillus bulgaricus, Streptococcus thermophilus and Bifidobacterium lactis, purchased from Danisco (China) Investment Limited) 0.014%. Said percentage is the mass ratio of each component relative to the flavored fermented milk final product.

[0188] The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0189] Two, produce the product of the present embodiment according to following process method:

[0190] see figure 1 Shown, the technological process of the product of the present embodiment mainly comprises:

[0191] Acceptance of raw milk: Acceptance according to the standard requirements of GB19301.

[0192] Centrifugal degreasing: Use an online degreasing separator, the operating temperature is 50°C to 55°C, and the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com