A kind of drying equipment and drying method of polyaluminum chloride series salts

A technology of polyaluminum chloride and drying equipment, which is used in drying solid materials, drying gas layout, lighting and heating equipment, etc. Heat transfer or cooling effect, footprint and space saving, health-preserving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

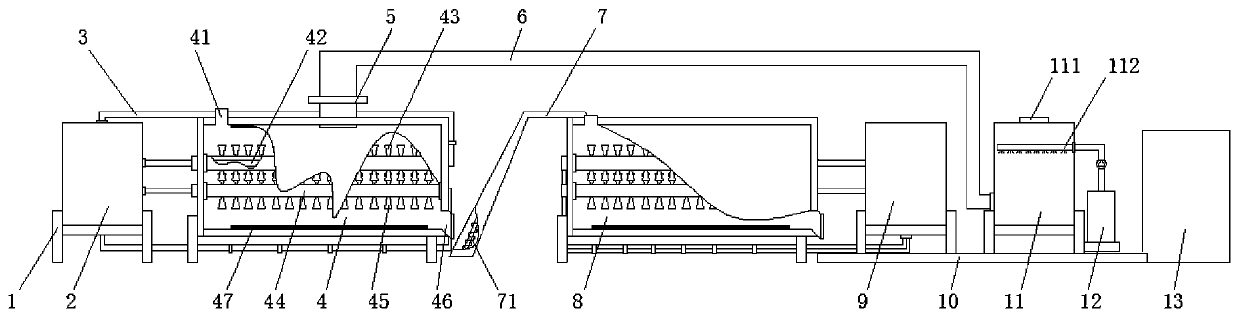

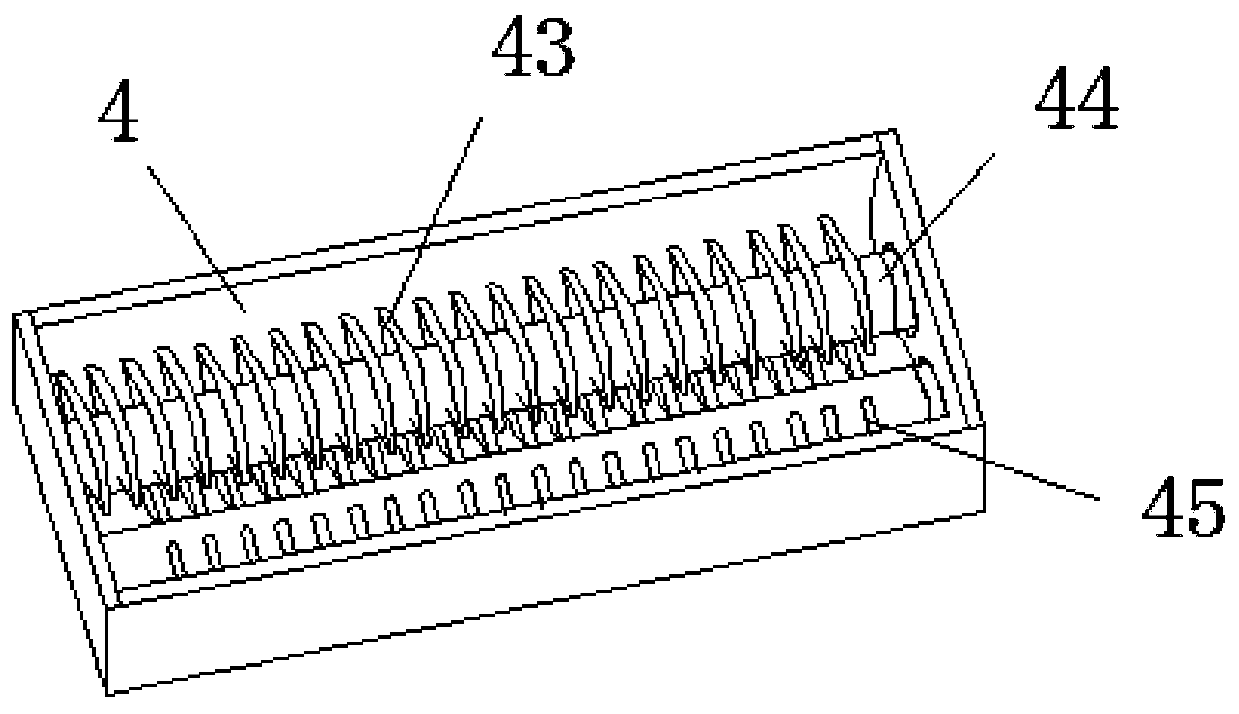

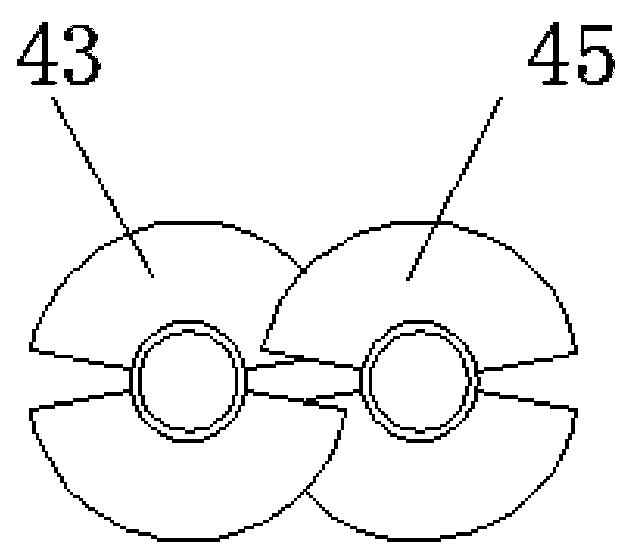

[0043] see Figure 1-5 , the present invention provides the following technical solutions: a drying equipment for polyaluminum chloride series salts, including a heat transfer oil tank 2, a drying mixer 4, a cooling device 8 and a steam scrubber 11, and the right side of the heat transfer oil tank 2 is provided with a drying A mixer 4, an acid mist steam delivery pipeline 6 is arranged above the drying mixer 4, a heat exchanger 5 is arranged on a side of the acid mist steam delivery pipeline 6 close to the drying mixer 4, and a side of the drying mixer 4 away from the heat transfer oil tank 2 The side is provided with a screw conveyor 7, and the inside of the screw conveyor 7 is provided with a screw shaft 71, and the side of the screw conveyor 7 away from the drying mixer 4 is provided with a cooling device 8, and the cooling device 8 is provided on a side away from the screw conveyor 7. There is a cooling water tank 9, the side of the cooling water tank 9 away from the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com