Apparatus for measuring diffusion coefficient during shale oil carbon dioxide huffing-puffing process and method thereof

A technology of diffusion coefficient and carbon dioxide, which is used in measurement devices, diffusion analysis, instruments, etc., can solve the problems of large influence of calculation results, unfavorable development and production, and deviation of diffusion coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

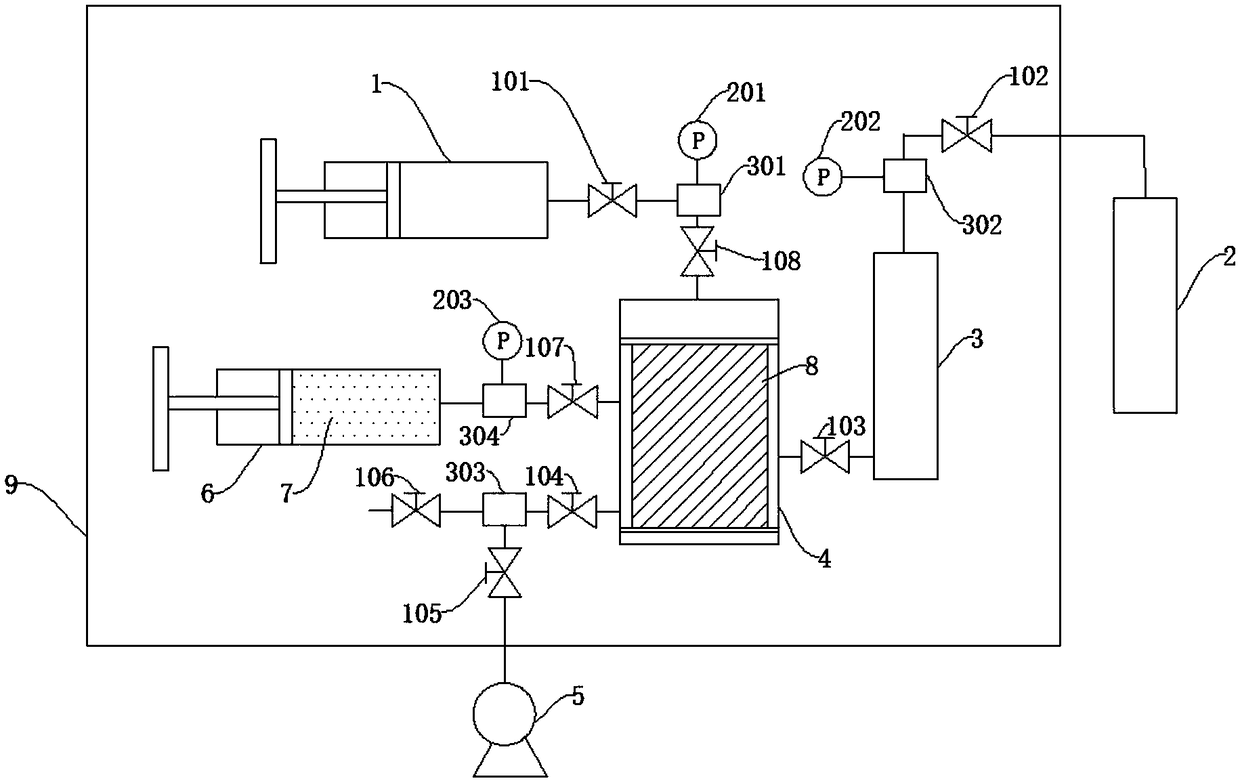

Method used

Image

Examples

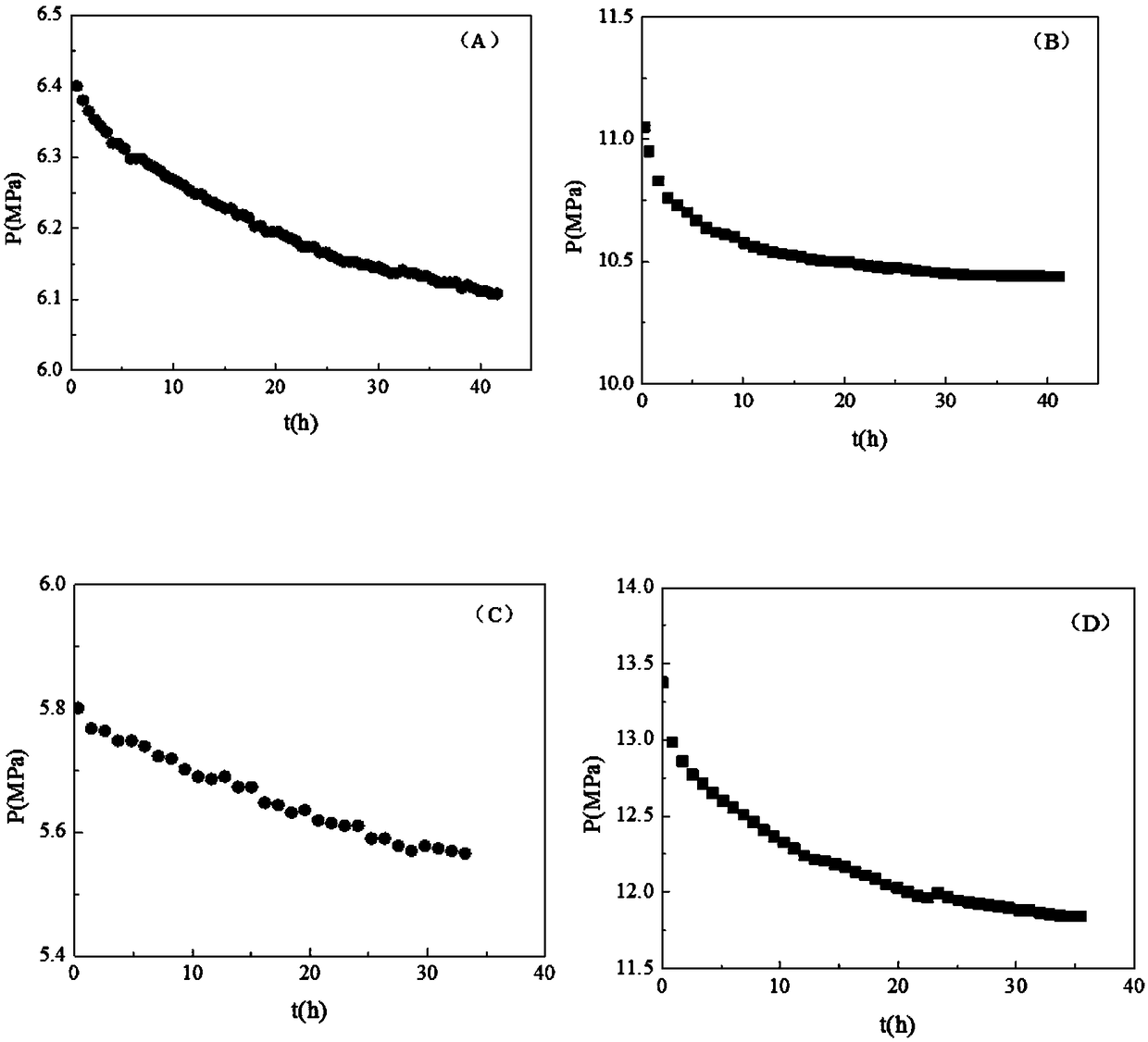

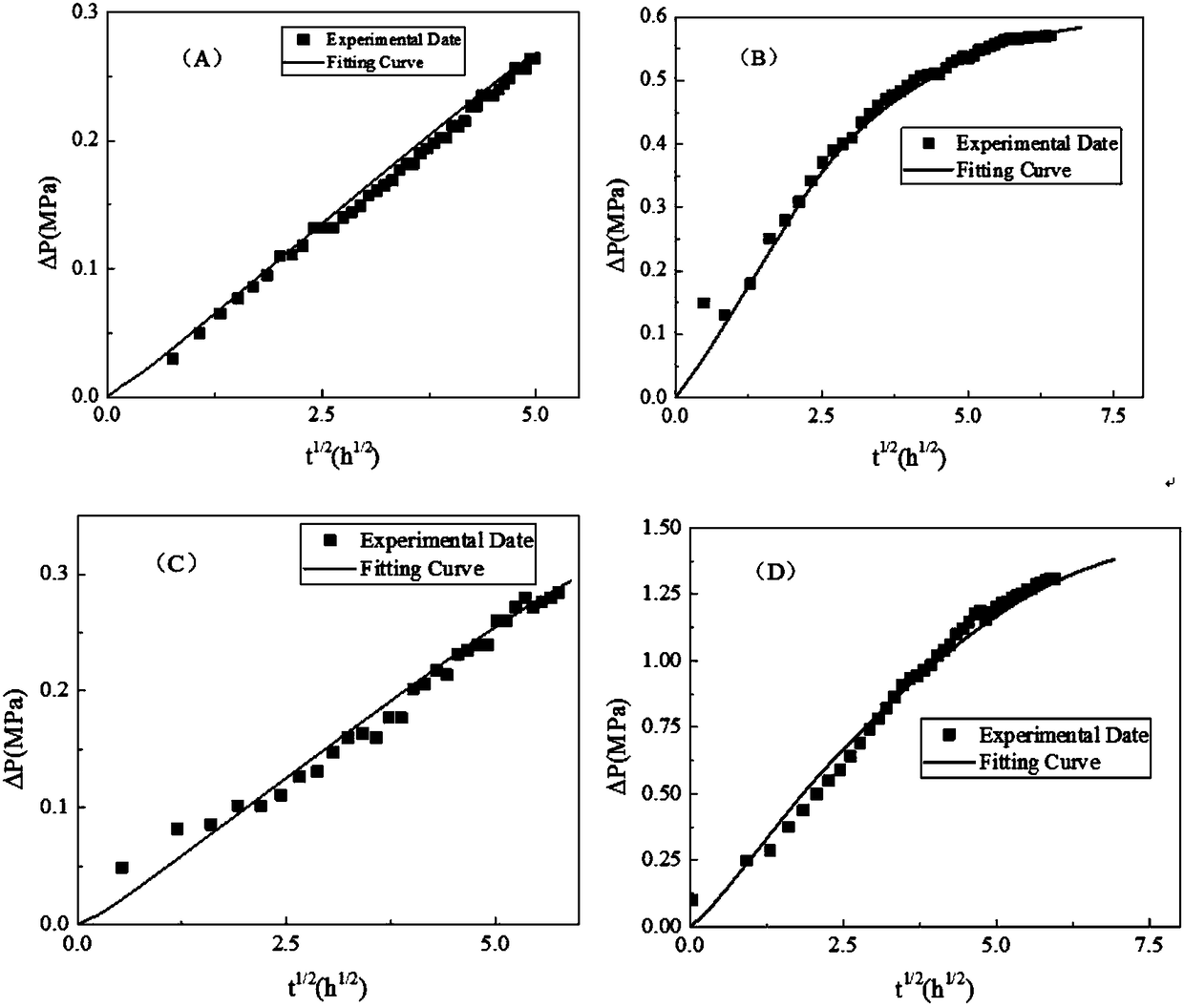

Embodiment 1

[0154] The thermostat 9 is set at a temperature of 60.0°C, and the core 8 sample, that is, shale I (see Table 1 for sample parameters) is placed in the radial core holder 4, the confining pressure is increased to 20 MPa, and after vacuuming and saturating the dodecane 7 , to CO 2 Inject a certain amount of CO into the high pressure vessel 3 2 Gas, maintain pressure 6.43MPa, CO 2 Inject the rock core 8 saturated with dodecane 7, and record the pressure change with time during the diffusion process through the second pressure sensor 202, such as figure 2 Shown in (A); through the calculation of this method, the obtained CO 2 The relevant parameters of the adsorption process are shown in Table 1, and the CO 2 The relevant parameters in the diffusion process of the shale core 8 are shown in Table 2. The curve of pressure changing with time calculated by this method is compared with the curve obtained from the experiment. image 3 (A), it can be seen that under this condition,...

Embodiment 2

[0156] The thermostat 9 is set at a temperature of 60.0°C, and the core 8 sample, that is, shale I (see Table 1 for sample parameters) is placed in the radial core holder 4, the confining pressure is increased to 20 MPa, and after vacuuming and saturating the dodecane 7 , to CO 2 Inject a certain amount of CO into the high pressure vessel 3 2 Gas, maintain pressure 11.05MPa, CO 2 Inject into the rock core saturated with dodecane 7, and record the pressure change with time during the diffusion process through the second pressure sensor 202, such as figure 2 Shown in (B); through the calculation of this method, the obtained CO 2 The relevant parameters of the adsorption process are shown in Table 2, and the CO 2 The relevant parameters in the diffusion process of the shale core 8 are shown in Table 3. The curve of pressure changing with time calculated by this method is compared with the curve obtained from the experiment. image 3 (B), it can be seen that under this condit...

Embodiment 3

[0158] Set the temperature of the thermostat 9 at 60.0°C, put the sample of the core 8, that is, shale II (see Table 1 for sample parameters) into the radial core holder 4, increase the confining pressure to 20 MPa, and then vacuumize and saturate the dodecane 7 , to CO 2 Inject a certain amount of CO into the high pressure vessel 3 2 Gas, maintain pressure 5.80MPa, CO 2 Inject into the rock core saturated with dodecane 7, and record the pressure change with time during the diffusion process through the second pressure sensor 202, such as figure 2 Shown in (C); through the calculation of this method, the obtained CO 2 The relevant parameters of the adsorption process are shown in Table 2, and the CO 2 The relevant parameters in the diffusion process of the shale core 8 are shown in Table 3. The curve of pressure changing with time calculated by this method is compared with the curve obtained from the experiment. image 3 (C), it can be seen that under this condition, CO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diffusion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com