Continuous factory boundary characteristic pollutant monitoring device

A technology of characteristic pollutants and monitoring devices, which is applied in the direction of measuring devices, instruments, signal transmission systems, etc., can solve the problems of inability to guarantee the authenticity, integrity and validity of online monitoring data, high failure rate and outage rate, and indecision making Accuracy and other issues, to achieve the effect of small size, high safety and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

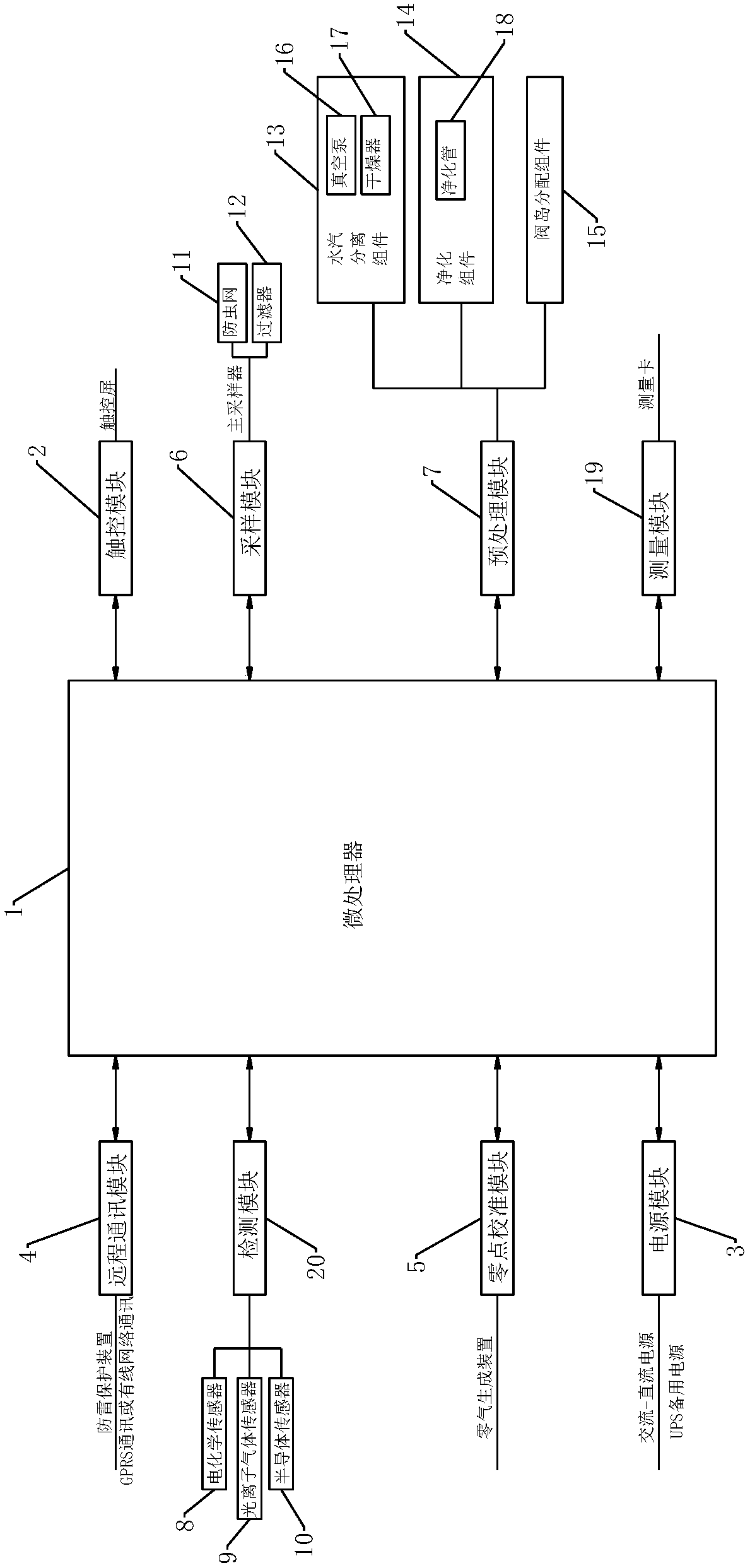

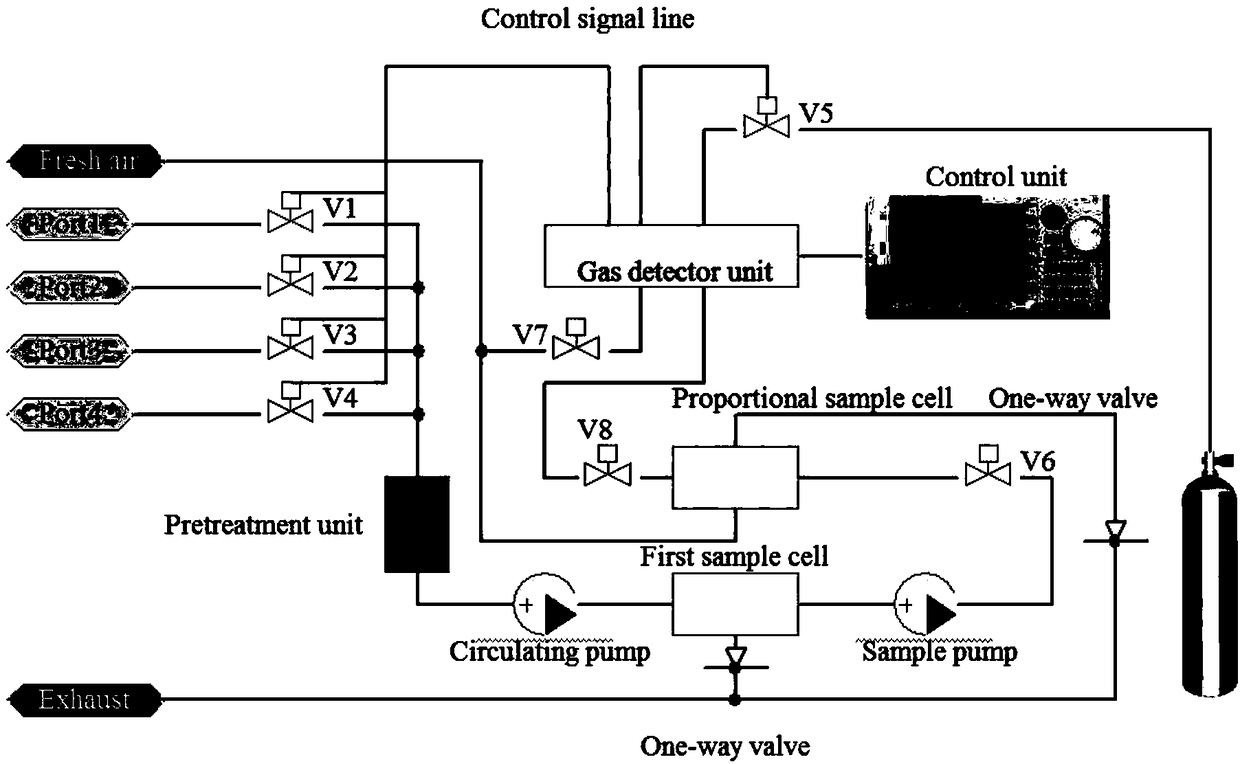

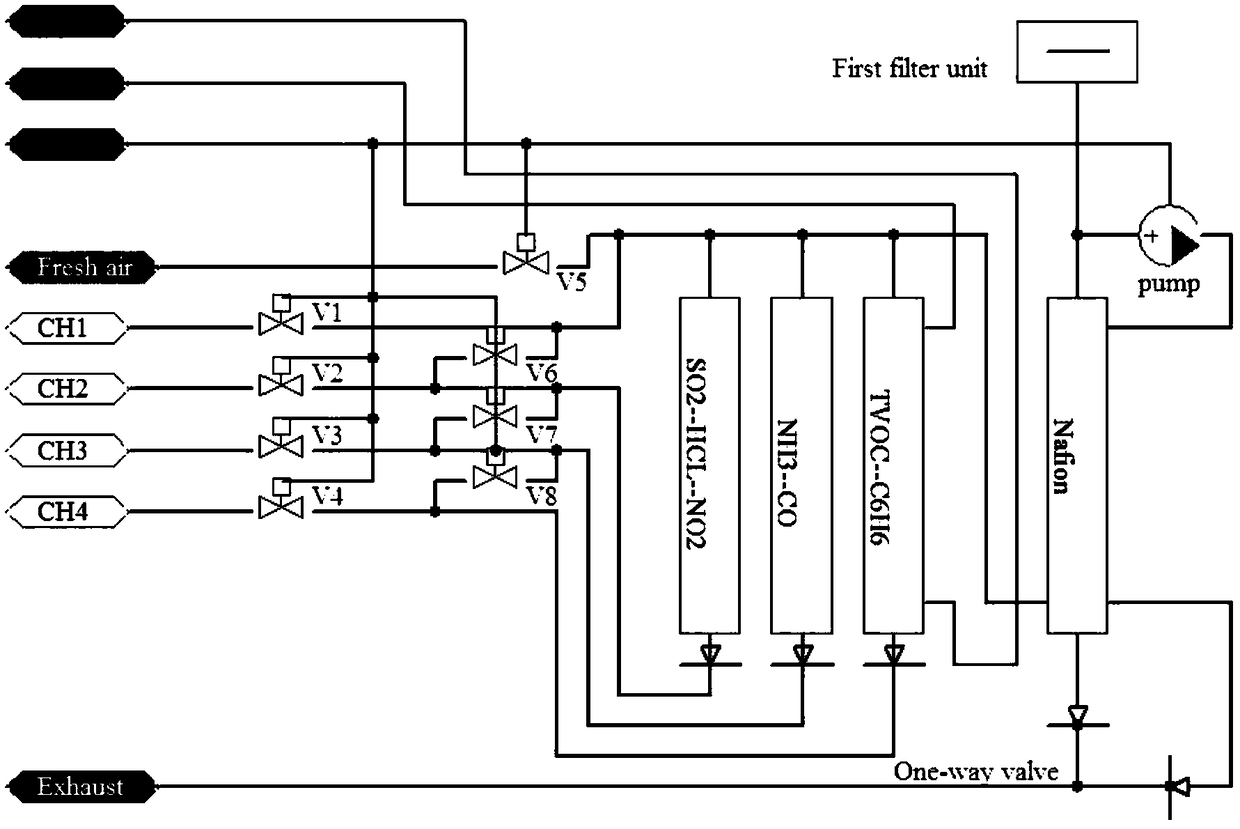

[0027] Such as figure 1 , figure 2 with image 3 As shown, a continuous monitoring device for characteristic pollutants at the factory boundary includes a microprocessor 1, a touch control module 2 and a power supply module 3. The microprocessor 1 is based on the ARM Cortex-M3 core, and the touch control The module 2 is connected to the microprocessor 1, and the power supply module 3 is connected to the microprocessor 1. The monitoring device also includes a remote communication module 4, a detection module 20, a zero point calibration module 5, a sampling module 6 and a preprocessing module 7; The remote communication module 4 is connected to the microprocessor 1, the remote communication module 4 uses GPRS communication or wired network communication, and the remote communication module 4 is connected to a lightning protection device equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com