Photovoltaic solder strip, preparation method therefor, and photovoltaic assembly

A photovoltaic ribbon and tin soldering technology, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of no obvious improvement in welding effect, increased cost, and large changes in solder composition, so as to ensure the repair rate of components, Good welding tension and improved photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention provides a method for preparing a photovoltaic ribbon, which is characterized in that it comprises:

[0047] A) heating, melting and mixing tin, lead, gallium and bismuth raw materials to obtain a molten liquid;

[0048] B) Contacting the surface of the conductive base tape with the molten liquid to obtain a photovoltaic soldering tape.

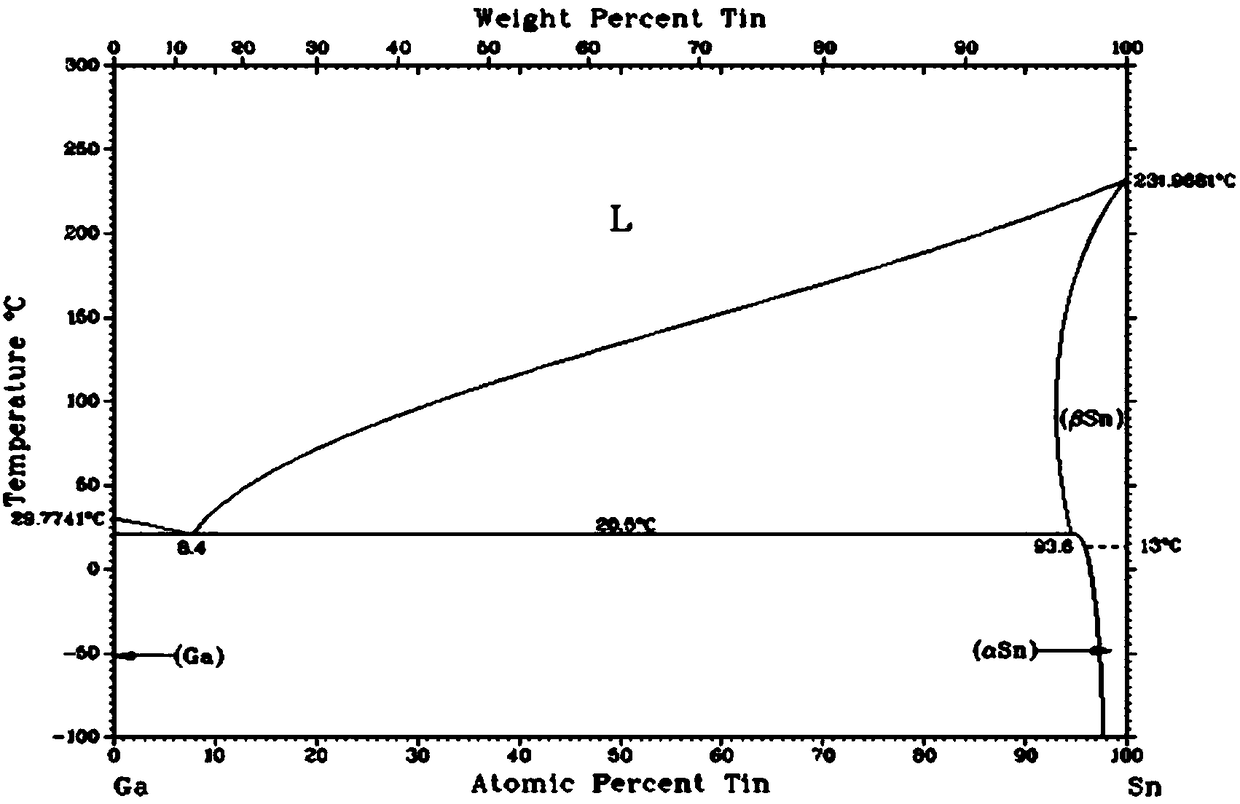

[0049] The preparation method of the photovoltaic ribbon provided by the present invention first heats, melts and mixes tin, lead, gallium and bismuth raw materials to obtain a melt.

[0050] According to the present invention, the mass ratio of the tin, lead, gallium and bismuth is preferably (55-65): (35-45): (0.0005-0.5): (1-5); more preferably (56-63) : (36-43): (0.01-0.3): (1-4); most preferably (56-58): (38-40): (0.01-0.05): (2-4).

[0051] The present invention does not limit its source, and it can be commercially available.

[0052] The present invention does not limit the specific manner of the heating and mel...

Embodiment 1~2

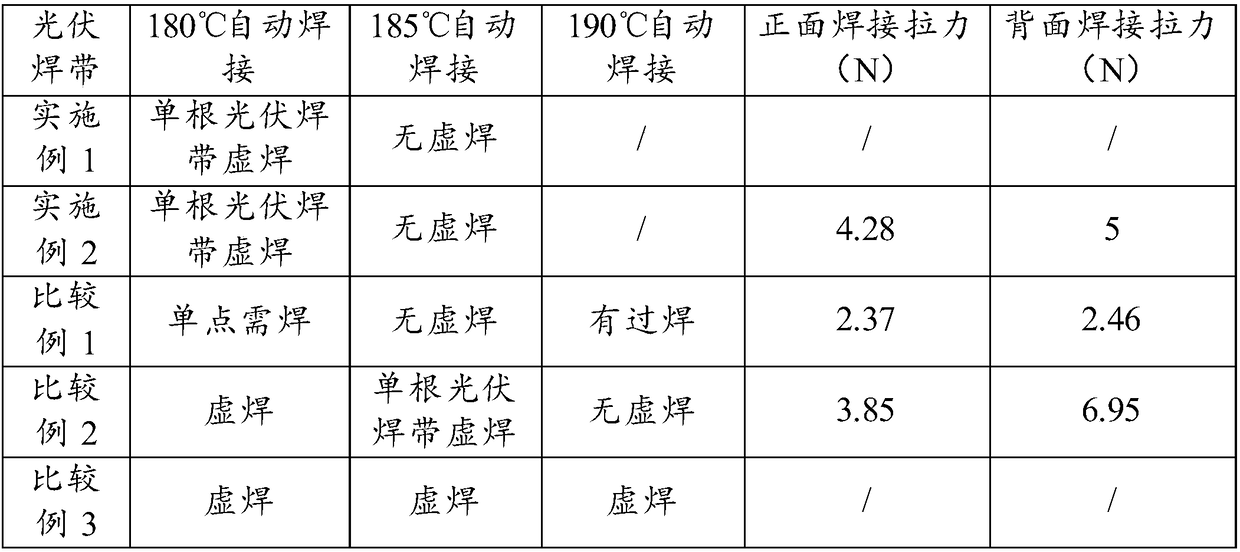

[0061] As shown in Table 1, mix the raw materials evenly to form a solder layer and melt it, then dip a copper strip with a thickness of 0.3 mm and a width of 1.5 mm in the molten liquid, and pass through the air knife device to obtain photovoltaic ribbons in sequence. Wherein, the thickness of the solder layer on the upper and lower surfaces of the copper base strip is 23±4um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com