Solid electrolyte having room-temperature conductivity polymer matrix and preparation method thereof

A technology of solid electrolyte and solid electrolyte, applied in the direction of solid electrolyte, electrolyte battery manufacturing, electrolyte, etc., can solve the problems of low liquid electrolyte conductivity, etc., achieve low cost, wide application prospects, and improve safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

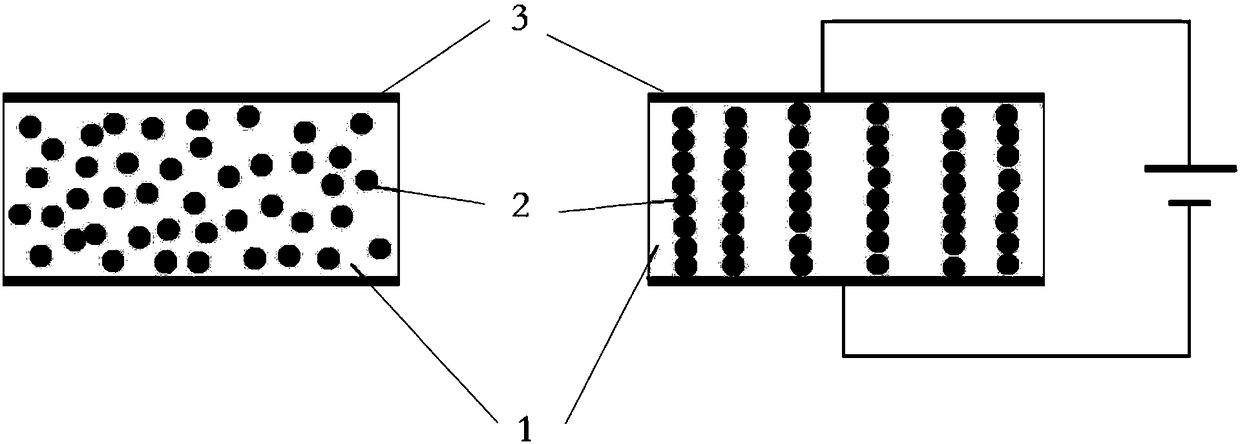

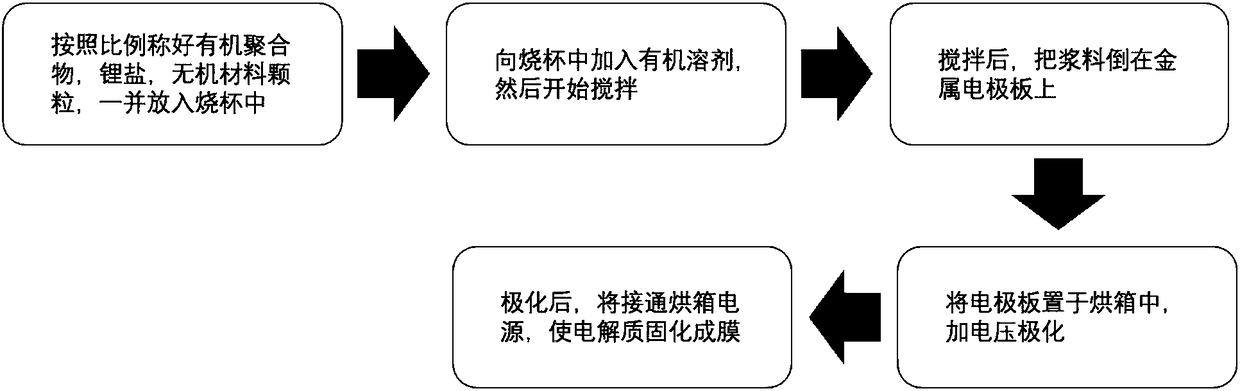

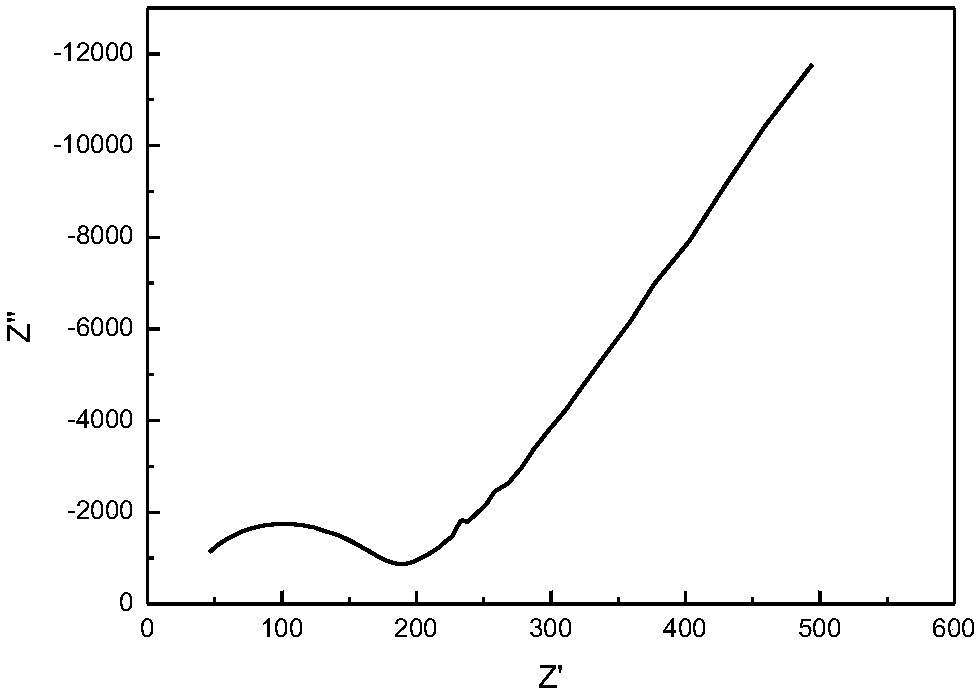

[0033] In this example, see figure 1 , a polymer-matrix solid electrolyte with room temperature conductivity, the organic polymer PEO is used as the matrix, and the lithium salt LiClO is uniformly doped in PEO 4 and inorganic material particles 2, inorganic material particles 2 using SiO 2 Particles, where SiO 2 The particles form an ordered distribution of chain particles in the radial direction of the solid electrolyte, so that SiO 2 The particles form fast ion channels at the interface of the electrolyte, forming a fast ion conductor structure. see figure 1 , the organic polymer PEO and the lithium salt LiClO 4The matrix composite material 1 is formed. Compared with the doped phase of the common composite material, the solid electrolyte of the polymer matrix in this embodiment makes the inorganic ceramic particles change from disordered distribution to ordered distribution during the solidification of the organic polymer electrolyte to form a film, and the prepared Hig...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, especially in that:

[0041] In this embodiment, a solid electrolyte with a polymer matrix with room temperature conductivity uses an organic polymer PAN as a matrix, uniformly doping lithium salt LiTFSI and inorganic material particles 2 in PAN, and the inorganic material particles 2 are LLZTO particles , in which the LLZTO particles form an ordered distribution of chain particles in the radial direction of the solid electrolyte, so that the LLZTO particles form fast ion channels at the interface of the electrolyte, forming a fast ion conductor structure. The organic polymer PAN and the lithium salt LiTFSI form a matrix composite material 1. Compared with the doped phase of the common composite material, the solid electrolyte of the polymer matrix in this embodiment makes the inorganic ceramic particles distributed randomly in the solidified film of the organic polymer electrolyte. Transform into an orderly distrib...

Embodiment 3

[0048] This embodiment is basically the same as the previous embodiment, and the special features are:

[0049] In this example, a solid electrolyte with a polymer matrix with room temperature conductivity uses organic polymer PEO as the matrix, and uniformly doped lithium salt LiClO in PEO 4 and inorganic material particles 2, PEO and LiClO 4 The mass ratio is 5:1, and the inorganic material particles 2 are made of Al 2 o 3 Particles, where Al 2 o 3 The particles form an ordered distribution of chain particles in the radial direction of the solid electrolyte, so that Al 2 o 3 The particles form fast ion channels at the interface of the electrolyte, forming a fast ion conductor structure. Organic polymer PEO and lithium salt LiClO 4 The matrix composite material 1 is formed. Compared with the doped phase of the common composite material, the solid electrolyte of the polymer matrix in this embodiment makes the inorganic ceramic particles change from disordered distributi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com