Preparation method of non-dense ordered polystyrene nanosphere template

A technology of polystyrene nano and spherical templates, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as no public reports, and achieve good controllability, uniform size, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of single-layer close-packed polystyrene nanosphere film

[0021] A. Select the P-type Si substrate and glass slide with a crystal orientation of (100), ultrasonically clean them with acetone and alcohol for 3 times, each time for 5 minutes, and rinse them with deionized water for 5 times; then wash them with H 2 SO 4 :H 2 o 2 =4:1 solution was boiled for 9 min, rinsed with deionized water for 5 times; finally the Si substrate was washed with HF:H 2 Soak in O=1:10 solution for 40 s, rinse with deionized water for 5 times;

[0022] B. Mix the polystyrene nanosphere solution with a diameter of 200 nm and the methanol solution according to the volume ratio of 1:1, and then use a micro-syringe to slowly flow 40 μL of the mixed solution into deionized water along the glass slide; add surfactant After the nanosphere film is stable, the deionized water is slowly removed with a peristaltic pump, and a single-layer close-packed polystyrene nanosphere film is ...

Embodiment 2

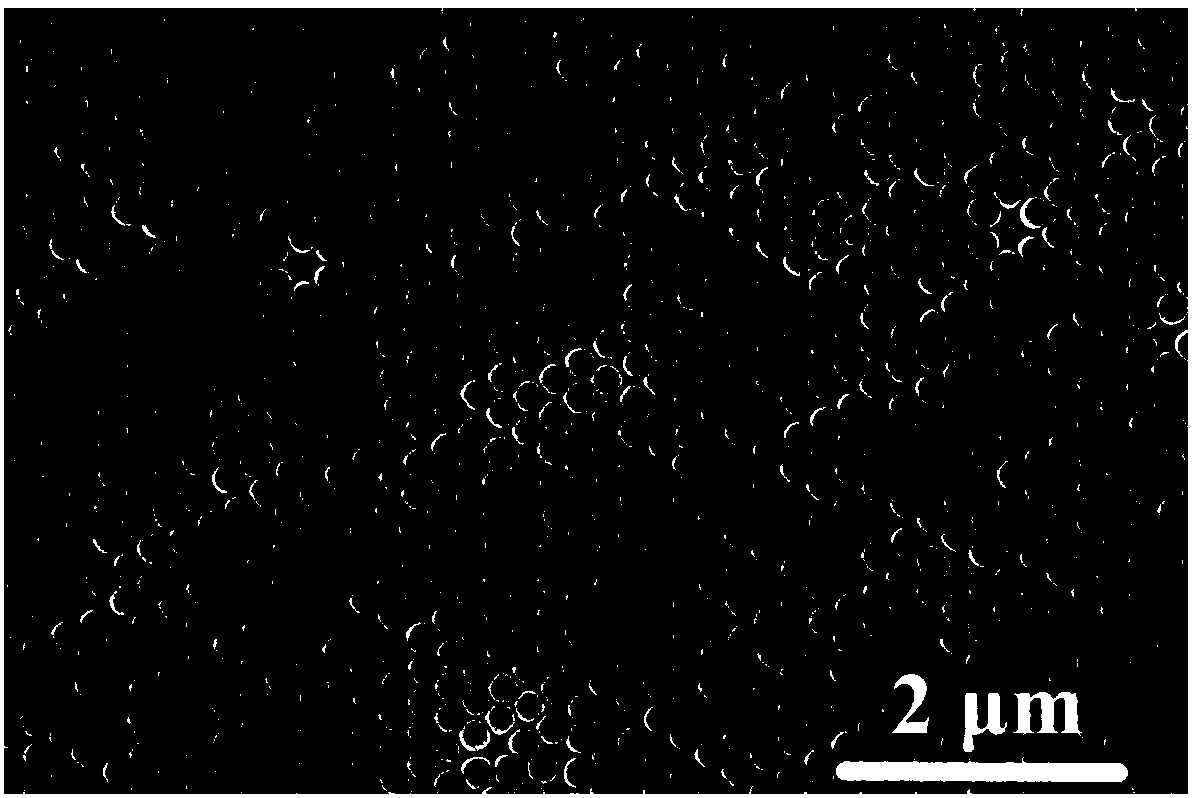

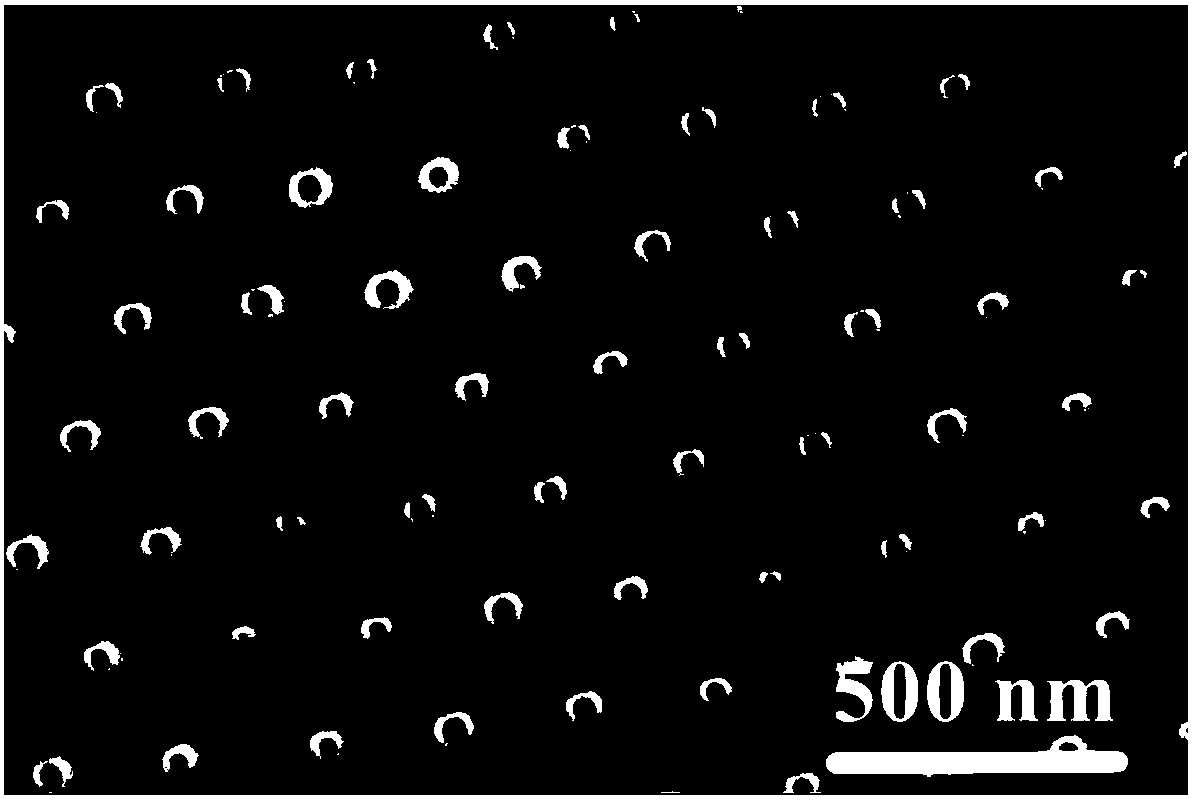

[0028] Similar to Example 1, the difference is that the diameter of polystyrene nanospheres is 100 nm, and the background vacuum is 8.0×10 -4 Pa, Ar + Ion beam current density 1.0 mA / cm 2 , and the etching time was 5 min. The average diameter of nanospheres in the non-close-packed ordered polystyrene nanosphere template is 54 nm, the distance between two nanospheres is 46 nm, and the etching rate is 17.32 nm / min.

Embodiment 3

[0030] Similar to Example 1, the background vacuum is 3.0×10 -3 Pa, Ar + Ion beam current density 2.0 mA / cm 2 , and the etching time was 14 min. The average diameter of the nanospheres in the non-close-packed ordered polystyrene nanosphere template is 120 nm, the distance between two nanospheres is 80 nm, and the etching rate is 11.43 nm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Etch rate | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com