Section fishing device

A technology of slicing and slice ring, which is applied in the field of slice picking devices, can solve problems such as the difficulty in judging the number of slices to be fished and the position of slices on the copper grid, increasing the complexity and difficulty of experimental operations, and increasing the difficulty of picking and displaying slices, etc. To achieve good temperature tolerance and corrosion resistance, improve speed and quality, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

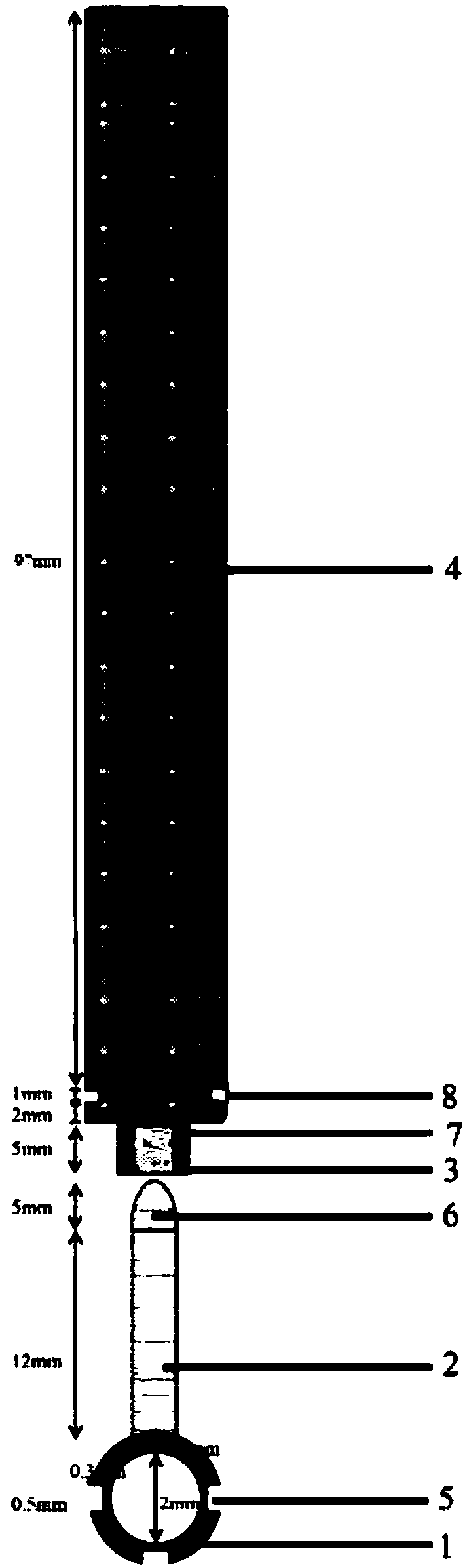

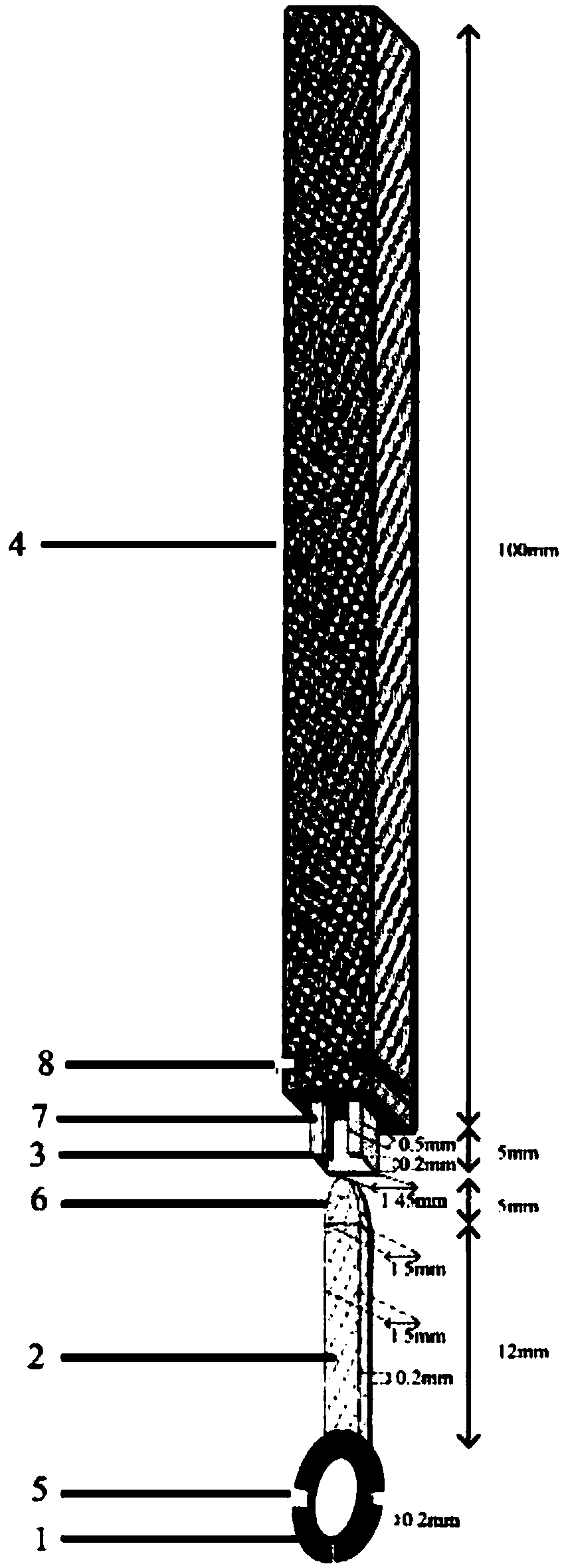

[0023] A kind of slice fishing device of the present invention such as figure 1 with figure 2 As shown, a slice fishing device is composed of a slice ring 1 , a slice ring handle 2 , a slice ring handle slot 3 and a hand-held rod 4 .

[0024] 1. The structure of each part

[0025] The lamination ring 1 is an annular metal ring with a thickness of 0.2mm, an inner diameter of the annulus of 2mm, and an outer diameter of 3mm. The annulus is provided with a dot opening 5 shaped as a square opening, and its depth is 0.3mm. mm, width 0.5mm, height 0.2mm, respectively located on the 3 o'clock and 9 o'clock positions perpendicular to the shank handle of the laminator and 6 o'clock opposite to the shank handle; the shank 2 is 12mm long and 1.5mm wide mm; the end of the fishing ring handle 2 is provided with a circular arc-shaped convex fis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com