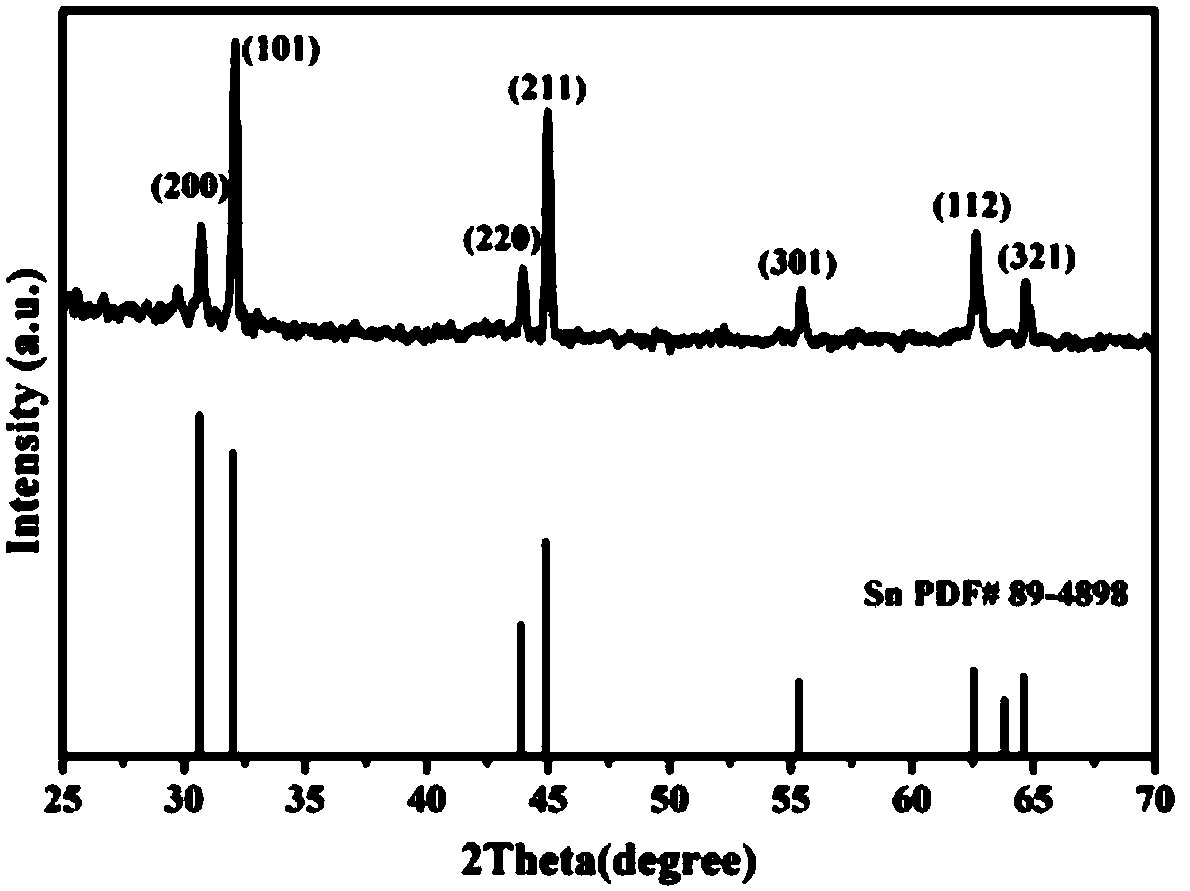

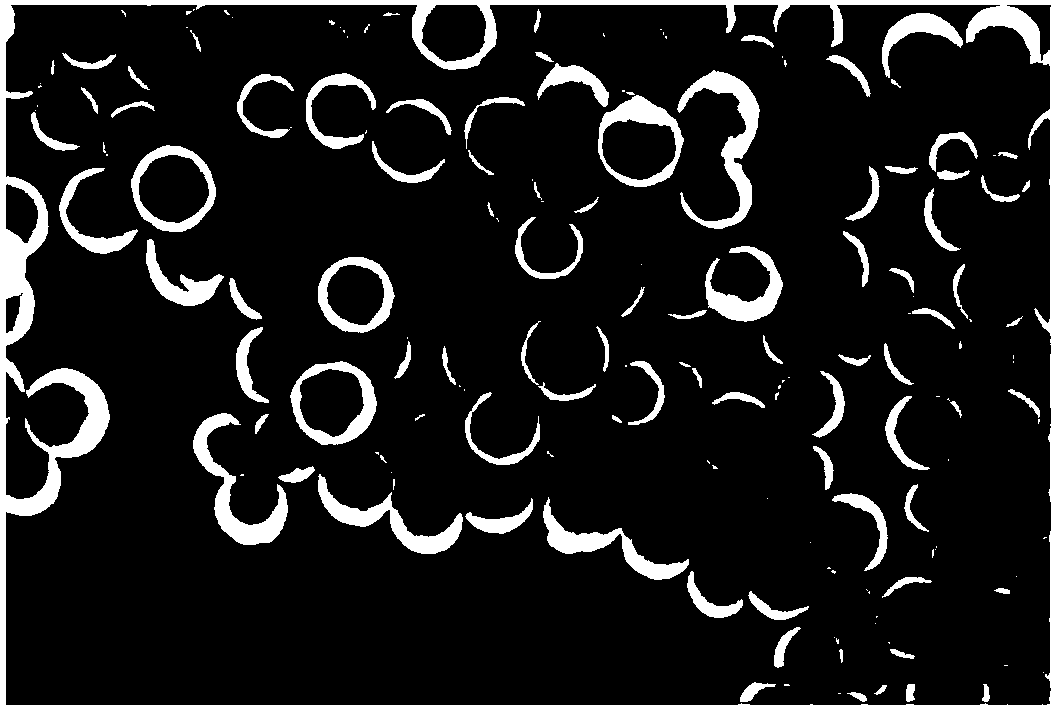

Sodium-ion battery negative electrode tin-carbon composite hollow sphere material and application thereof

A sodium-ion battery and hollow sphere technology, applied to battery electrodes, secondary batteries, circuits, etc., to achieve the effects of abundant raw material reserves, stable charge-discharge cycle performance, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1). Weigh 0.0600g SnCl respectively 2 , 0.1g triaminophenol, 0.1ml formaldehyde and 1ml ammonia water were dissolved in 30ml deionized water, and the mixed solution was stirred and reacted on a magnetic stirrer for 30 minutes to obtain solution A;

[0031] 2). Add 20ml of acetone to solution A and let it stand;

[0032] 3). Centrifuge the solution A after standing, put it in an oven and dry it at 75°C for 12 hours to obtain product B;

[0033] 4). Put the product B into a quartz boat, place the quartz boat in a high-temperature tube furnace and react at 800°C for 6 hours to obtain the tin-carbon composite hollow sphere material.

[0034] The electrochemical test method of the obtained tin-carbon composite hollow sphere negative electrode material is as follows:

[0035] Adopt button cell to study the electrochemical performance of negative electrode material, adopt DMF to be solvent, the formula of pole plate is according to: active material: PVDF: the ratio of acetyl...

Embodiment 2

[0037] 1). Weigh 0.300g SnCl respectively 2 , 0.1g triaminophenol, 0.1ml formaldehyde and 1ml ammonia water were dissolved in 30ml deionized water, and the mixed solution was stirred and reacted on a magnetic stirrer for 30 minutes to obtain solution A;

[0038] 2). Add 20ml of acetone to solution A and let it stand;

[0039] 3). Centrifuge the solution A after standing, put it in an oven and dry it at 75°C for 12 hours to obtain product B;

[0040] 4). Put the product B into a quartz boat, place the quartz boat in a high-temperature tube furnace and react at 800°C for 6 hours to obtain the tin-carbon composite hollow sphere material.

[0041] Gained C / Sn / C composite hollow sphere negative electrode material electrochemical test method is as follows:

[0042] A button cell is used to study the electrochemical performance of the negative electrode material, DMF is used as the solvent, and the formula of the pole piece is mixed with DMF solvent according to the ratio of active...

Embodiment 3

[0044] 1). Weigh 0.4562g SnCl respectively 2 , 0.1g triaminophenol, 0.1ml formaldehyde and 1ml ammonia water were dissolved in 30ml deionized water, and the mixed solution was stirred and reacted on a magnetic stirrer for 30 minutes to obtain solution A;

[0045] 2). Add 20ml of acetone to solution A and let it stand;

[0046] 3). Centrifuge the solution A after standing, put it in an oven and dry it at 75°C for 12 hours to obtain product B;

[0047] 4). Put the product B into a quartz boat, place the quartz boat in a high-temperature tube furnace and react at 800°C for 6 hours to obtain the tin-carbon composite hollow sphere material.

[0048] The electrochemical test method of the obtained tin-carbon composite hollow sphere negative electrode material is as follows:

[0049] Adopt button cell to study the electrochemical performance of negative electrode material, adopt DMF to be solvent, the formula of pole sheet is according to: active material: PVDF: the ratio of acetyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com