Preparation method and application method of chiral-atom-free helically chiral all-cis polyphenylacetylene derivative materials

A technology of helical chirality and dimethylol, which is applied in the field of preparation of helical polymers, can solve problems such as little research, and achieve the effects of good chiral resolution, low cost and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of helical chiral all-cis polyacetylene DDOHPA without chiral atoms:

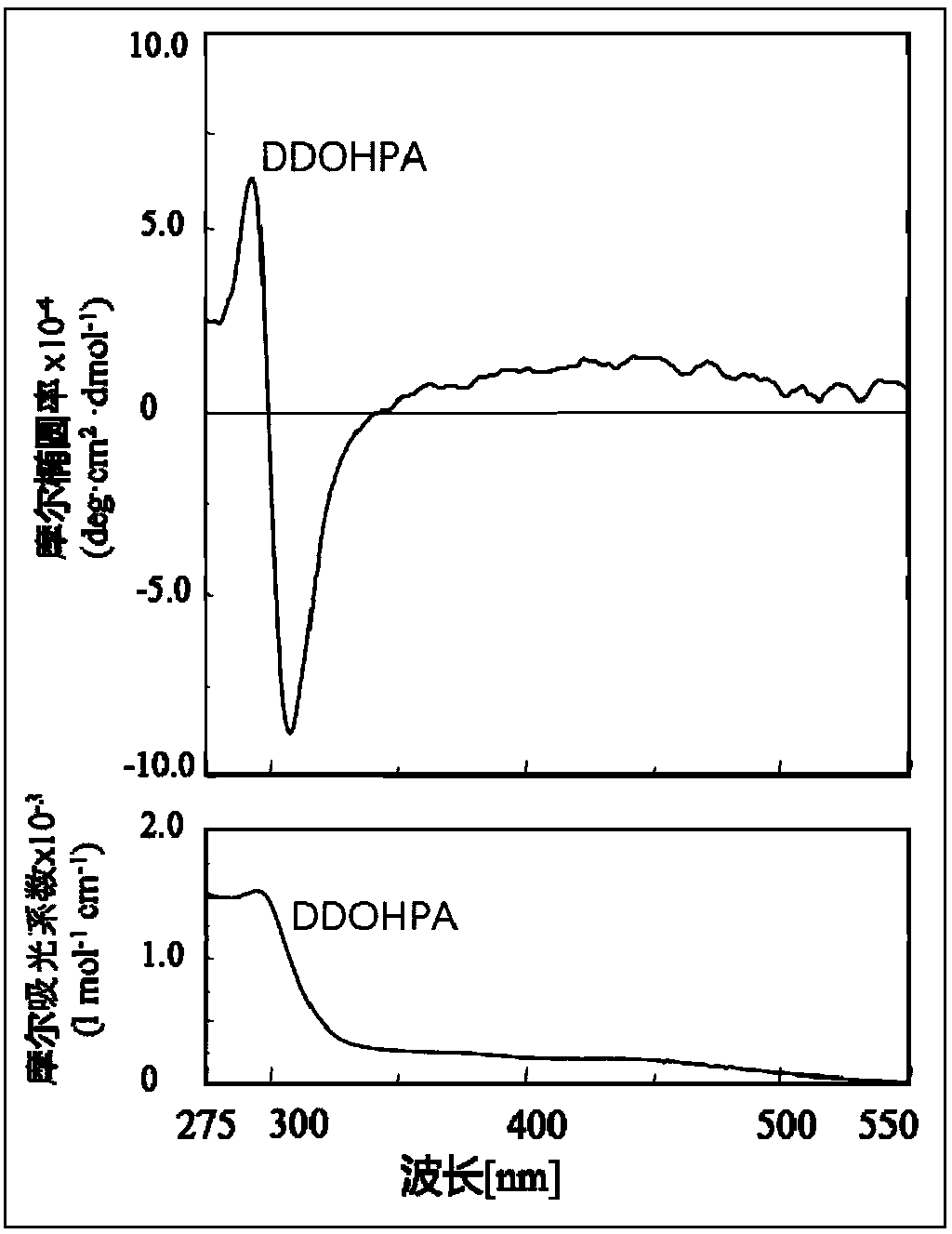

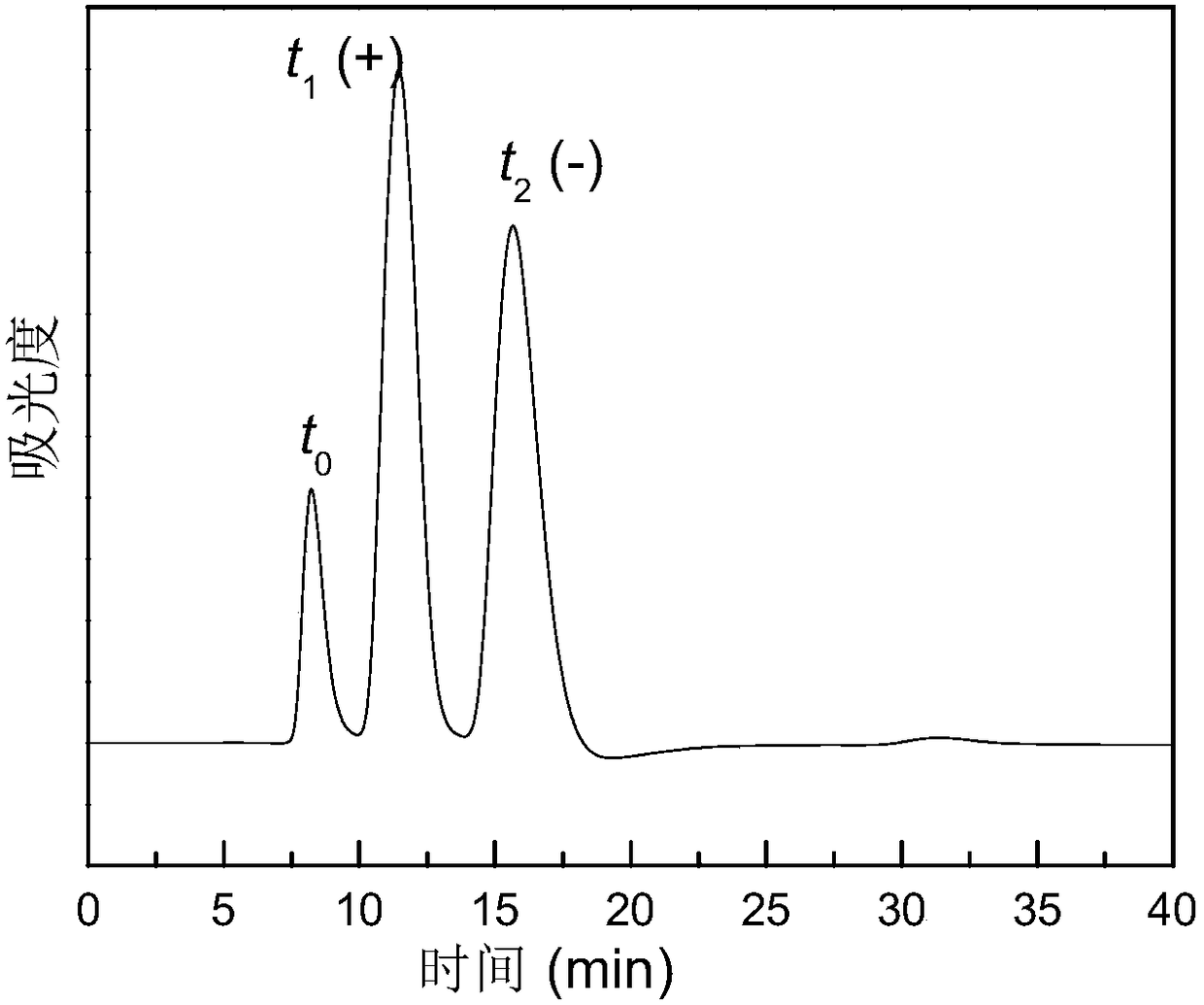

[0030] Measure 50 mL of (R)-α-methylbenzylamine and bubble it with helium for 5 minutes. Weigh 0.50 g non-optically active all-cis polyphenylene vinylene DDOHPA, and dissolve it in 50 ml of (R)-α-methylbenzylamine after bubbling helium at normal temperature and pressure to prepare a solution. This solution was poured into a dialysis bag (cellulose dialysis bag, molecular weight cut off 5000). After the dialysis bag is sealed, place the dialysis bag containing the solution in a beaker filled with 500 ml of tetrahydrofuran, heat the beaker to 35 degrees Celsius, and replace the tetrahydrofuran every 1 hour. After replacing 3 times, take out the dialysis bag and open it, use a dropper to take out the solution in the dialysis bag and drop it into 500ml of methanol for precipitation and precipitate an orange-red precipitate. After centrifugation, vacuum-dry the resulting precipitate for 4...

Embodiment 2

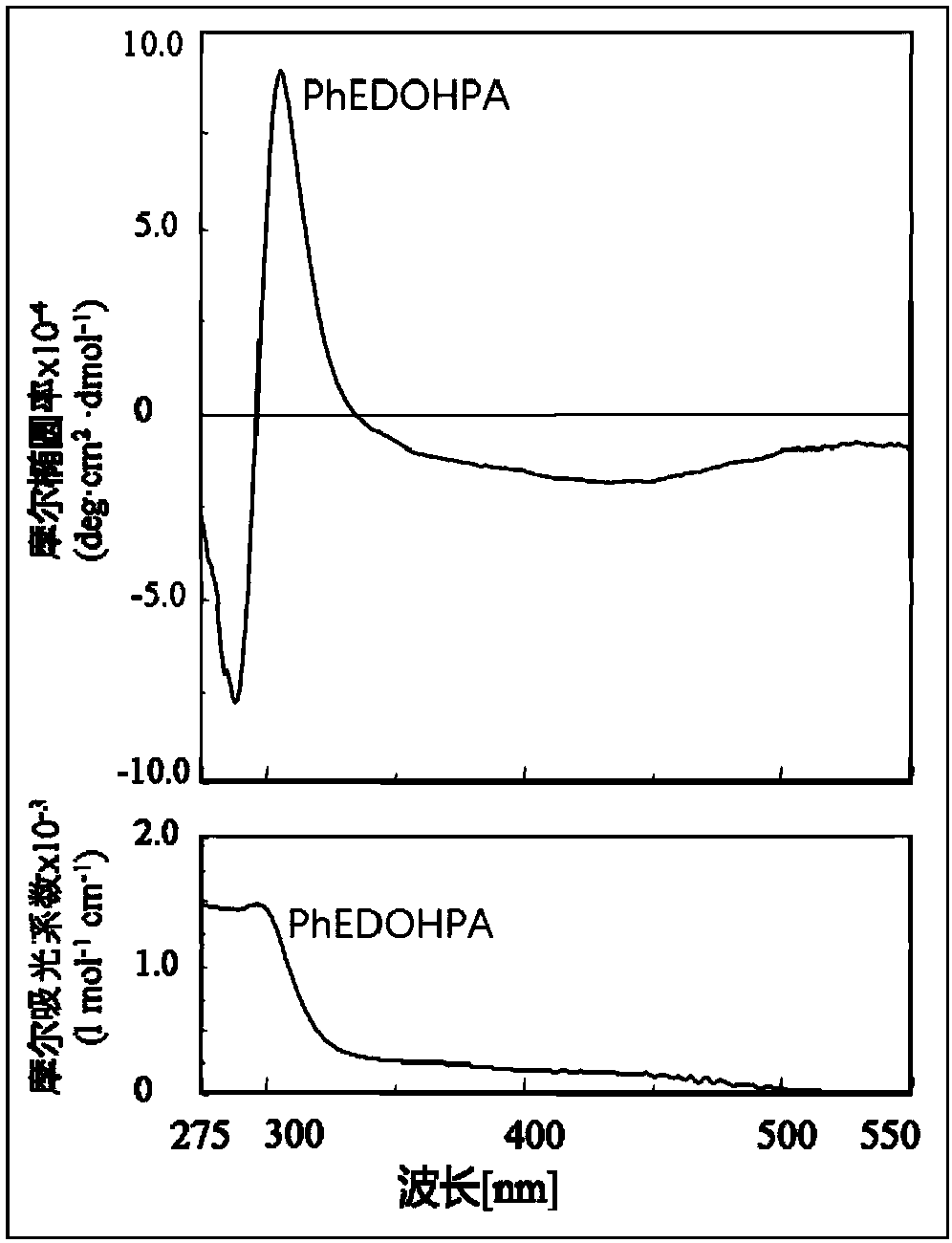

[0035] (1) Preparation method of helical chiral all-cis polyphenylene vinylene PhEDOHPA without chiral atoms: measure 50 mL of (S)-α-methylbenzyl alcohol, and use helium gas bubbling for 5 minutes. Weighed 0.50 g non-optically active all-cis polyphenylene vinylene PhEDOHPA, and dissolved it in 50 ml of (S)-α-methylbenzyl alcohol bubbled with helium at normal temperature and pressure to prepare a solution. This solution was poured into a dialysis bag (cellulose dialysis bag, molecular weight cut off 5000). After the dialysis bag is sealed, the dialysis bag filled with the solution is placed in a beaker filled with 300ml toluene, the beaker is heated to 45 degrees Celsius, and the toluene is replaced every 45 minutes. After replacing 3 times, take out the dialysis bag and open it, use a dropper to take out the solution in the dialysis bag and drop it into 500ml of methanol for precipitation and precipitate an orange-red precipitate. After centrifugation, vacuum-dry the resulting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com