High crystallization rate polyamide, preparation method and application thereof

A technology of polyamide and high crystallization, which is applied in the field of polymers, can solve the problems of mechanical properties and yellowing resistance, affecting the injection molding process, and slow crystallization rate of materials, so as to shorten the molding cycle, inhibit the generation of gel, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

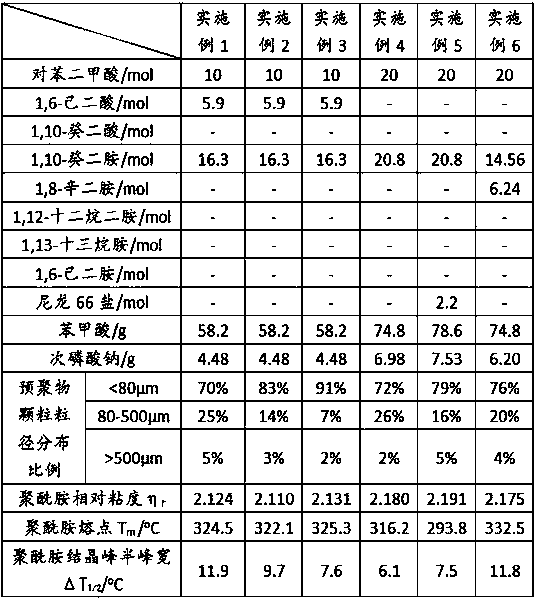

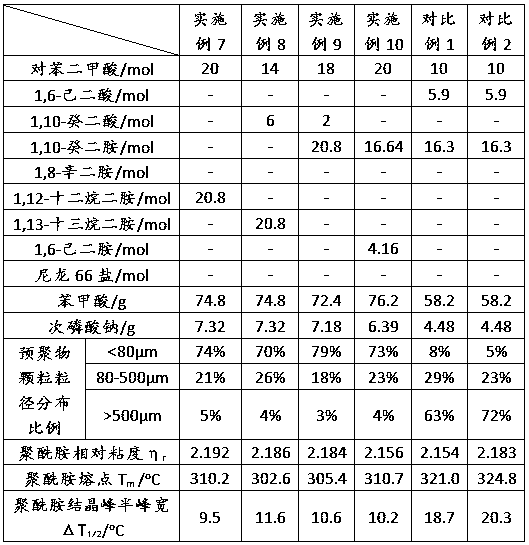

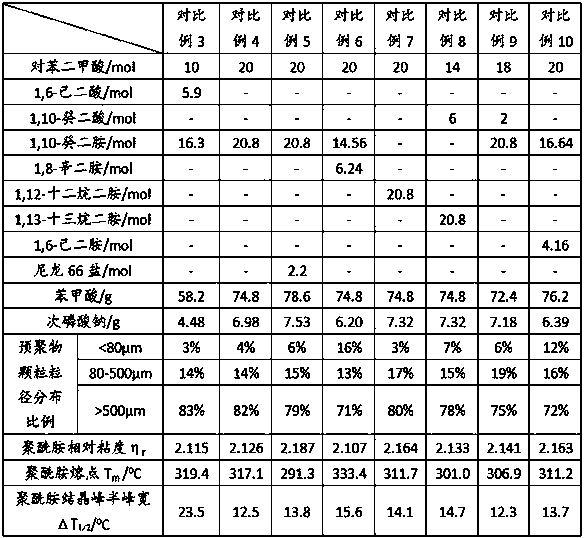

Embodiment 1-10

[0050] The preparation method of embodiment 1-10 high crystallization rate polyamide:

[0051] Pre-polymerization step: According to the ratio in Table 1, add the weighed dicarboxylic acid, diamine and nylon salt into the pressure vessel equipped with magnetic coupling stirring, condenser, gas phase port, feeding port and pressure explosion-proof port , benzoic acid, sodium hypophosphite, filled with N after vacuuming 2 To normal pressure, repeat vacuuming and then fill with N 2 process three times, and finally the N 2 The pressure rose to 0.3MPa. The temperature was raised to 220°C with stirring over 2 hours, the reaction mixture was stirred at 220°C for 1 hour, then the temperature of the reactants was raised to 230°C with stirring. The reaction continued for 2 hours at a constant temperature of 230°C and a constant pressure of 2.2MPa. The pressure was kept constant by removing the formed water. After the reaction was completed, it was discharged in a spray state, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com