Alkaline washing agent for equipment in dairy industry as well as preparation method and application method thereof

A cleaning agent and alkaline technology, applied in the field of alkaline cleaning agents for CIP equipment in the dairy industry, can solve the problems of long cleaning time, large water consumption, environmental impact, etc., to save time and energy, reduce pickling frequency, reduce The effect of sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The cleaning of the dairy industry CIP equipment pipeline provided by the present embodiment is composed of the following components in parts by mass:

[0052] NaOH 50,

[0054] Chelating agent 18,

[0055] Surfactant 0.5,

[0056] Sodium polyacrylate 2,

[0057] water treatment agent 2,

[0058] water 22.5.

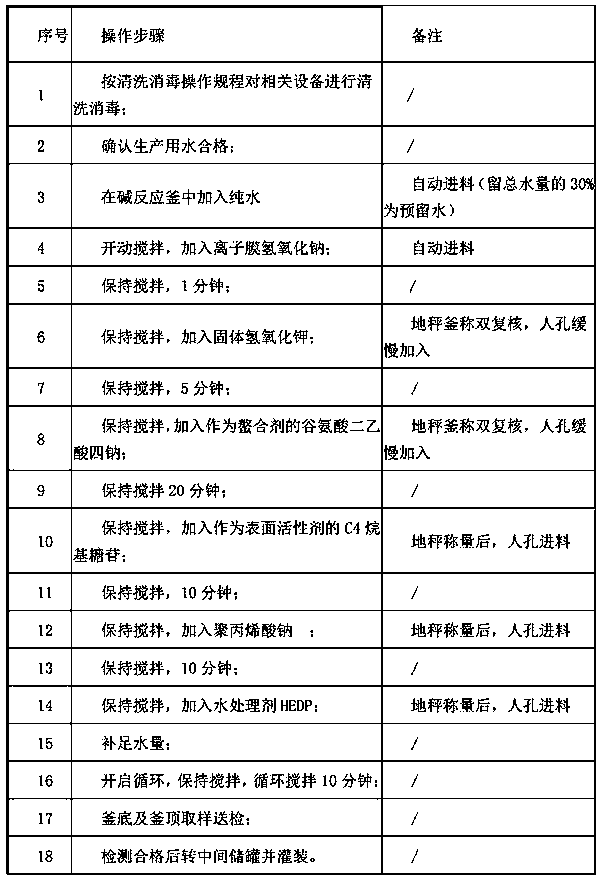

[0059] The specific production process is as follows (according to this process is most conducive to maintaining the stability of the alkaline cleaning agent system):

[0060]

[0061] Instructions:

[0062] Dilute the alkaline cleaning agent prepared in this example with water until the mass percent concentration of the alkaline cleaning agent is 0.5% (mass of alkaline cleaning agent / (mass of alkaline cleaning agent + mass of water)), 60°C-85°C Under certain conditions, the dosage form of the CIP equipment is cleaned in a cycle for 20 minutes, and then washed with water.

[0063] The use effect of this embodiment:

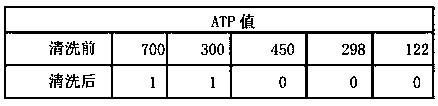

[00...

Embodiment 2

[0072] The cleaning of the dairy industry CIP equipment pipeline provided by the present embodiment is composed of the following components in parts by mass:

[0073] NaOH 46,

[0074] Potassium hydroxide 10,

[0075] Chelating agent 10,

[0076] Surfactant 2,

[0077] Sodium polyacrylate 1,

[0078] water treatment agent 3,

[0079] water 28.

[0080]Production process: the same as in Example 1, wherein the chelating agent material is disodium edetate, the surfactant material is octyl decyl glucoside, and the water treatment agent material is aminotrimethylene phosphonic acid (ATMP).

[0081] Usage method: same as embodiment 1

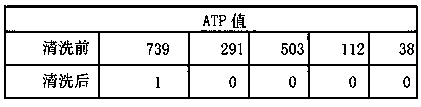

[0082] The use effect of this embodiment:

[0083] The cleaned metal surface maintains the original color and luster of the metal; after cleaning, the surface is clean, there is no increase in the deposition of dirt such as fat, and the surface has no greasy feeling;

[0084] The alkaline cleaning agent of this embodiment is specially used for...

Embodiment 3

[0091] The cleaning of the dairy industry CIP equipment pipeline provided by the present embodiment is composed of the following components in parts by mass:

[0092] NaOH 46,

[0093] Potassium hydroxide 10,

[0094] Chelating agent 15,

[0095] Surfactant 1,

[0096] Sodium polyacrylate 0.5,

[0097] water treatment agent 3,

[0098] water 24.5.

[0099] Production technology: with embodiment 1. The chelating agent material is sodium tripolyphosphate, the surfactant material is lauryl glucoside, and the water treatment agent material is hydroxyethylidene diphosphonic acid (HEDP).

[0100] Using method: with embodiment 1.

[0101] The use effect of this embodiment:

[0102] The cleaned metal surface maintains the original color and luster of the metal; after cleaning, the surface is clean, there is no increase in the deposition of dirt such as fat, and the surface has no greasy feeling;

[0103] The alkaline cleaning agent of this embodiment is specially used for cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com