Anti-scaling electrodialysis system based on pH control and treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

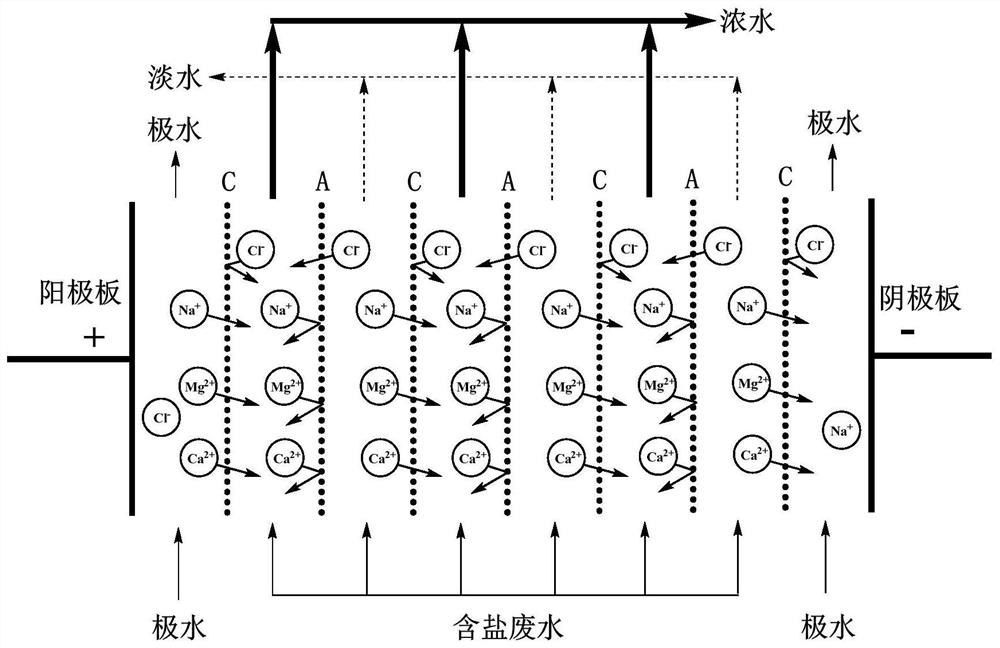

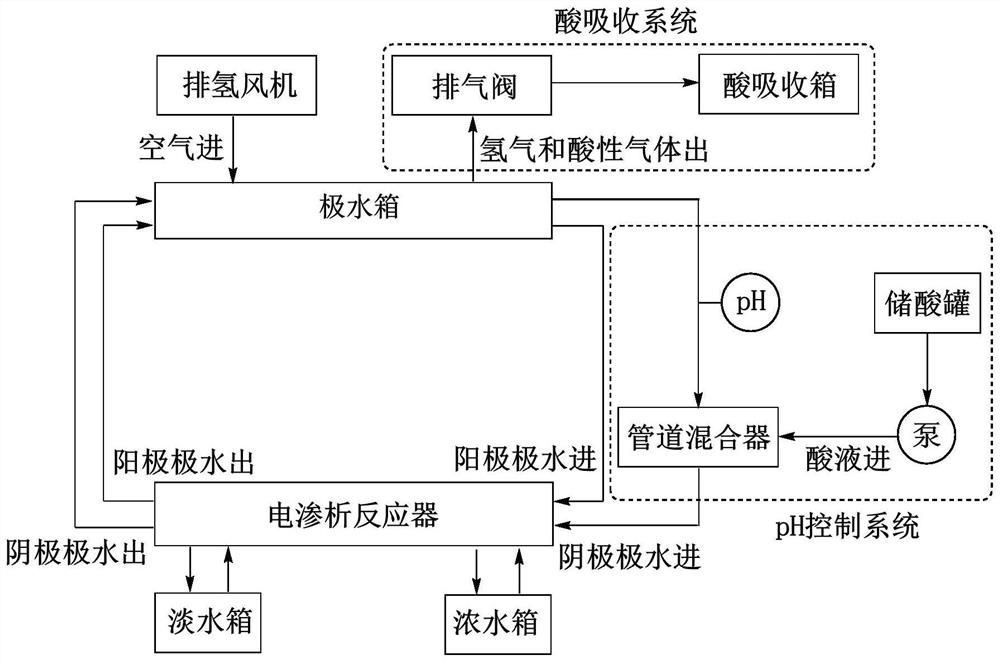

[0029]There are various scaling control factors, mainly including water quality, water temperature, flow rate, heat exchange temperature difference, corrosion and scale inhibitors, etc. Among them, pH is an important indicator of water quality. Lowering the pH of the treatment solution can greatly reduce the scaling of calcium and magnesium. tendency. Such asfigure 1 As shown, during the working process of the electrodialysis membrane stack, the divalent cations (mainly calcium ions and magnesium ions) in the adjacent channels will enter the polar water channel through diffusion and ion exchange, and will continue to generate OH on the surface of the cathode plate.-After the combination, calcium and magnesium scale will be precipitated and attached to the surface of the cathode plate. At this time, the migration rate of divalent ions in the cathode electrode water is far higher than the migration rate of divalent ions in the anode electrode water, and the divalent ions are quickly l...

Embodiment 2

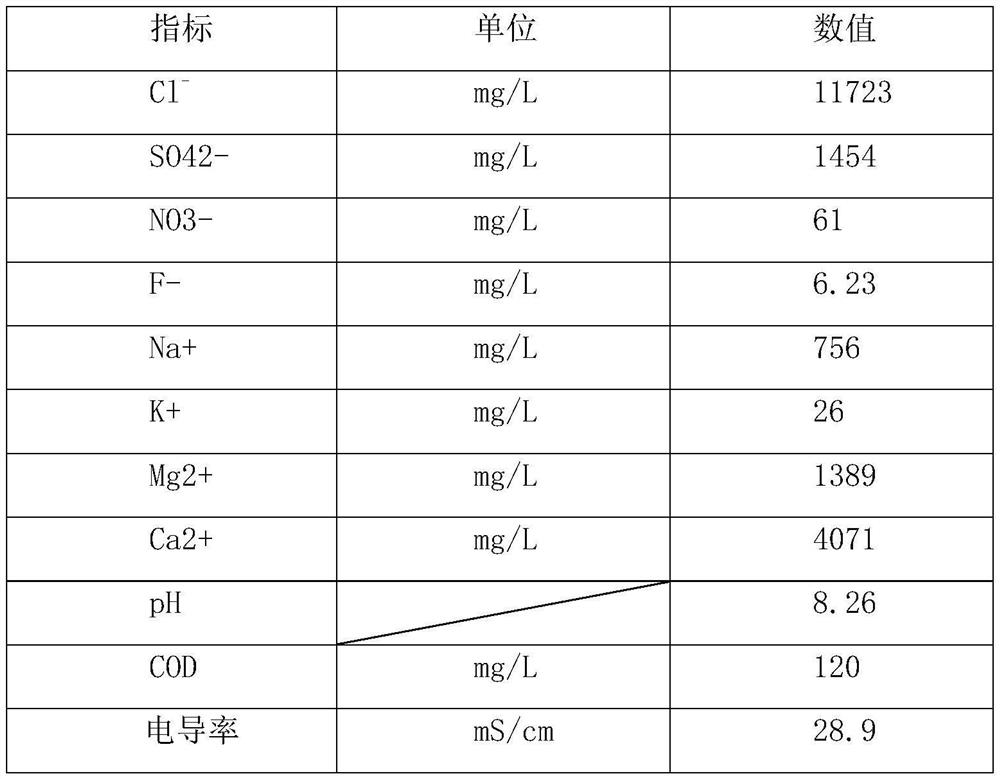

[0035]A coal-fired power plant uses an electrodialysis system to concentrate desulfurization wastewater. The desulfurization wastewater has not been softened before entering the system, and the calcium ion concentration and magnesium ion concentration are relatively high. The specific water quality is shown in the table below:

[0036]

[0037]The electrodialysis system uses 3% sodium chloride solution as the polar water. Due to the high hardness of desulfurization wastewater, calcium ions and magnesium ions will pass through the polar membrane under the action of electric field and permeation, causing the hardness of the polar water to rise rapidly. In a certain treatment process, the newly configured extreme water calcium ion concentration is 9mg / L and magnesium ion concentration is 3mg / L. After 5 hours of treatment, the calcium ion concentration increases to 1377mg / L and the magnesium ion concentration increases to 259mg / L. L. After 7 days of operation, the electrodialysis membrane sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com