Electrospinning preparation method for hydrophilic/hydrophobic regulable thin film

A technology of electrospinning and electrospinning technology, which is applied in the field of electrospinning preparation of polymer films, can solve the problems of cumbersome and complicated operation methods, fixed contact angle angles, and limitations in application fields, and expand the scope of application fields and equipment The effect of economical price and effective and precise regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Dissolve polymethyl methacrylate (poly (methylmethacrylate), PMMA) and disperse red 1 (disperse red 1, DR1) in butyl acetate (n-Butyl acetate, BTA), and prepare to contain 1.1% The spinning solution of polymethyl methacrylate and 0.075% DR1 is placed in an electrospinning device with a needle with a diameter of 0.6mm, the fixed injection speed is set to 0.3ml / h, and the feeding distance is 12cm. Electrospinning was performed at room temperature with different working electric field strengths. The prepared film was received on a glass substrate covered with tinfoil.

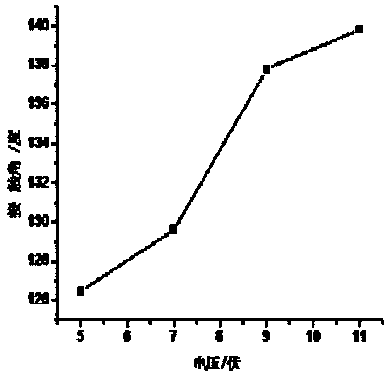

[0028] The prepared PMMA / DR1 composite film was tested and characterized by a contact angle tester, figure 2 It is the result of 5 tests.

Embodiment 2

[0029] Example 2: Dissolve polyformaldehyde (polyformaldehyde, POM,) and disperse red 19 (disperse red 1, DR19) in dimethylformamide ( N , N -Dimethylformamide, DMF), prepared into a spinning solution containing 1.5% polyoxymethylene and 0.09% DR1, placed it in an electrospinning device with a needle diameter of 0.6mm, and set a fixed injection speed of 0.3ml / h , the feeding distance is 12cm, and the electrospinning is carried out at room temperature under different working electric field strengths. The prepared film was received on a glass substrate covered with tinfoil.

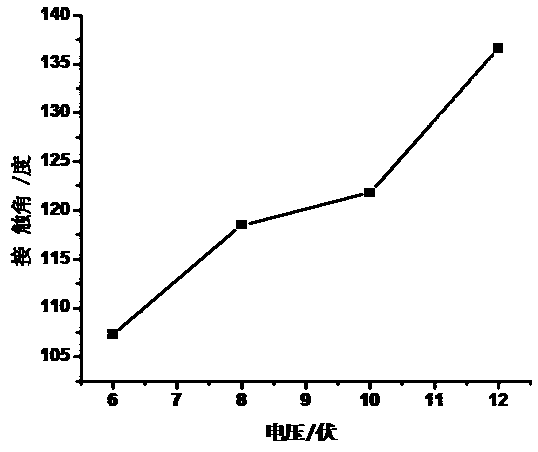

[0030] The prepared POM / DR19 composite film was tested and characterized by a contact angle tester, image 3 It is the result of 5 tests.

Embodiment 3

[0031] Example 3: Polyvinylpyrrolidone (poly(vinyl pyrrolidone), PVP) and disperse red 98 (disperse red 1, DR98) were dissolved in chlorobenzene (Chlorobenzene), and prepared to contain 2.0% polyvinylpyrrolidone and 0.10% DR1 The spinning solution is placed in an electrospinning device with a needle diameter of 0.6mm, the fixed injection speed is set to 0.3ml / h, the feeding distance is 12cm, and electrostatic spinning is carried out at room temperature under different working electric field strengths. spinning. The prepared film was received on a glass substrate covered with tinfoil.

[0032] The prepared PVP / DR98 composite film was characterized by a contact angle tester, Figure 4 It is the result of 5 tests.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com