Preparation method and application of a modified polysiloxane-based solid electrolyte membrane

A solid electrolyte membrane and polysiloxane-based technology, which is applied in the direction of solid electrolyte, electrolyte storage battery manufacturing, non-aqueous electrolyte, etc., can solve the problems of narrow electrochemical window and low ion conductivity, and achieve good mobility and low glass The effect of changing the transition temperature and broadening the range of application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1P

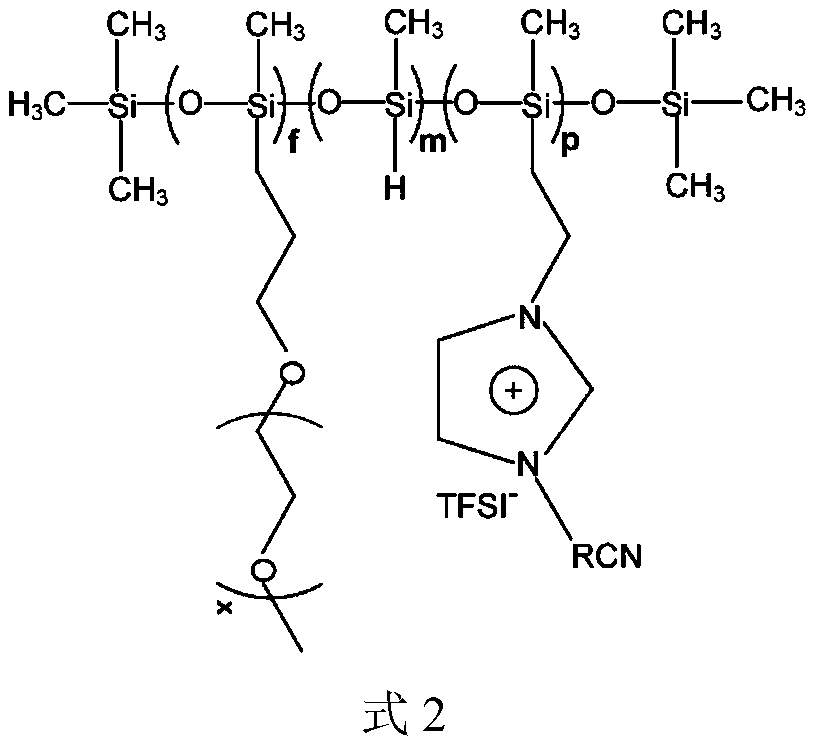

[0026] The synthesis of implementation example 1PEO modified PMHS

[0027] A certain amount of PMHS was weighed and mixed with an appropriate amount of anhydrous toluene into a 50ml three-necked flask, and then placed in an oil bath and heated and stirred. Appropriate amount of PEO(m (PEO) :m (PHMS) =2), an appropriate amount of chloroplatinic acid catalyst was dissolved and mixed in anhydrous toluene, and then slowly added into a three-necked flask. in N 2 Under a protective atmosphere, the mixed solution was first reacted at 50°C for 2-4 hours, and then heated to 80°C to react until the carbon-carbon double bond in the mixed solution disappeared (infrared verification), and the product was washed with n-hexane to remove impurities, and then distilled under reduced pressure The solvent was removed to obtain a PEO-grafted PMHS backbone polymer (P-PMHS).

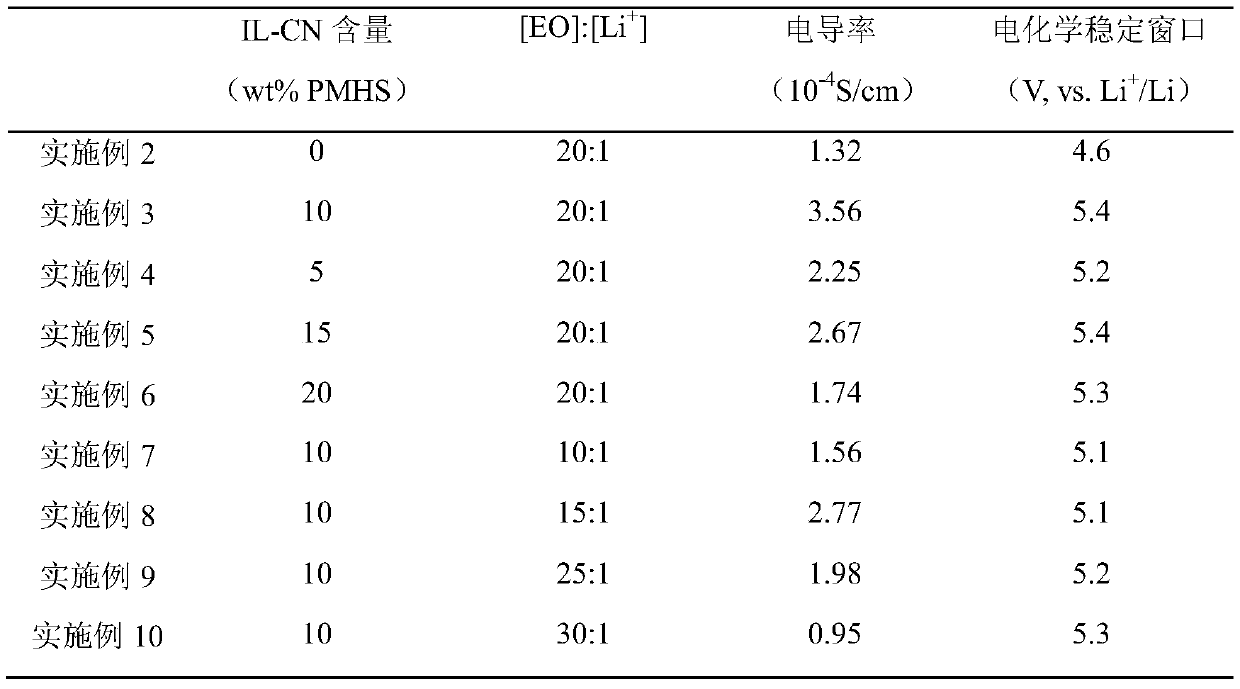

Embodiment 2

[0028] The preparation of implementation example 2 polymer lithium ion batteries

[0029] (1) Put the P-PMHS polymer prepared in Example 1 into a 100ml round bottom flask, add an appropriate amount of anhydrous acetonitrile solvent, and stir to dissolve. Subsequently, an appropriate amount of chloroplatinic acid catalyst, triethylene glycol divinyl ether crosslinking agent, bistrifluoromethylsulfonylimide lithium (adding lithium salt amount to meet [EO]:[Li + ]=20:1) into the round bottom flask, stirred at room temperature for 12h, and mixed well.

[0030] (2) Pour the mixed solution of (1) into a polytetrafluoroethylene mold, place it in a vacuum oven, heat and cross-link and solidify to obtain a solid polymer electrolyte membrane, and transfer it to a glove box for standby.

[0031] (3) LiFePO 4 The positive electrode material, PVDF, and conductive carbon black are mixed according to the mass ratio of 80:10:10, and an appropriate amount of NMP is added to stir evenly, and ...

Embodiment 3

[0033] The preparation of implementation example 3 polymer lithium ion batteries

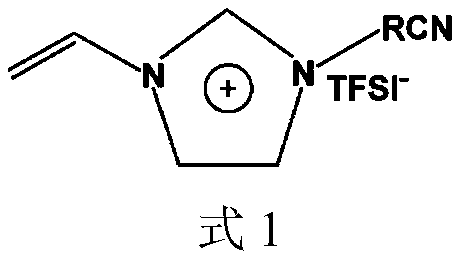

[0034] (1) Weigh a certain amount of PMHS and mix them with an appropriate amount of anhydrous toluene and add them into a 50ml three-neck flask, then heat and stir in an oil bath. Appropriate amount of PEO(m (PEO) :m (PHMS)=2), cyanoimidazolium ionic liquid (10wt% PMHS) and an appropriate amount of chloroplatinic acid catalyst were dissolved in anhydrous toluene and mixed, then slowly added into a three-necked flask. in N 2 Under a protective atmosphere, the mixed solution was first reacted at 50°C for 2-4 hours, and then heated to 80°C to react until the carbon-carbon double bond in the mixed solution disappeared (infrared verification), and the product was washed with n-hexane to remove impurities, and then distilled under reduced pressure Removal of solvent yielded IL-CN and PEO double-grafted PMHS polymer (PIN-PMHS).

[0035] (2) Put the PIN-PMHS polymer prepared in (1) in a 100ml round...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com