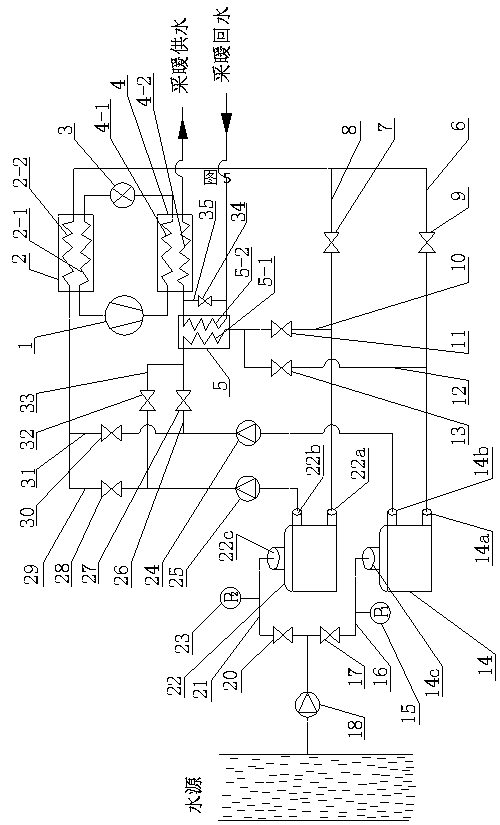

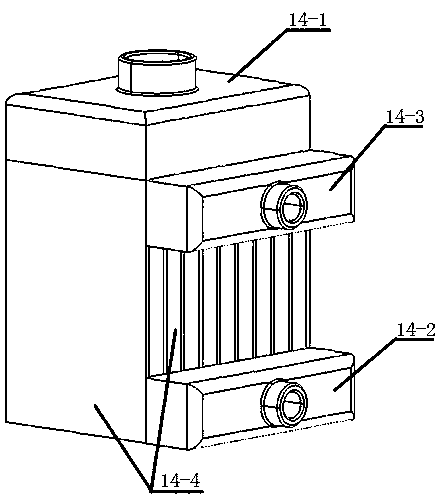

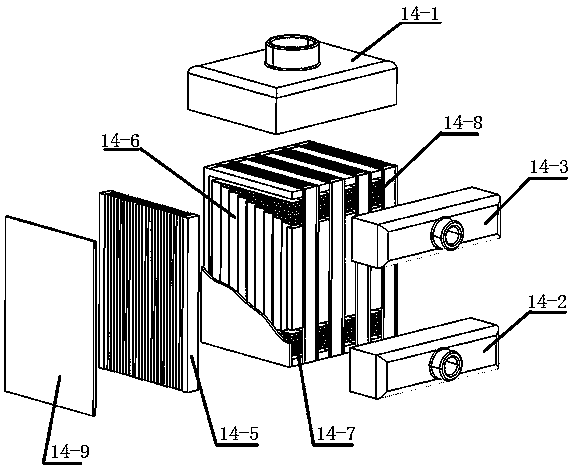

Heat pump system based on open type cold water solidification heat exchanger

A heat pump system and heat exchanger technology, applied in heat pumps, refrigerators, refrigeration components, etc., can solve problems such as reduced service life, easy damage to auger scrapers and heat exchange tubes, and difficult operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0112] Embodiment 4. The heat pump system based on the open cold water solidification heat exchanger in this embodiment 4 is basically the same in structure and working process as the heat pump system based on the open cold water solidification heat exchanger in Embodiment 1. The difference is that The ninth solenoid valve 13 and the eleventh solenoid valve 11 are replaced by the first electric three-way valve; the fifth solenoid valve 9 and the seventh solenoid valve 7 are replaced by the second electric three-way valve; The third solenoid valve 20 is replaced by the third electric three-way valve; the eighth solenoid valve 27 and the tenth solenoid valve 32 are replaced by the fourth electric three-way valve; the fourth solenoid valve 30 and the sixth solenoid valve 28 are replaced by the fifth electric three-way valve valve instead.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com