Current threshold judgment-based pre-withdrawing saturation driving method of reverse conduction IGBT gate pole

A current threshold, reverse conduction technology, applied in electrical components, electronic switches, high-efficiency power electronic conversion, etc., can solve problems such as abnormal system operation, difficulty, waveform oscillation, etc., to optimize dynamic and static characteristics, and save energy. , the effect of enhanced heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

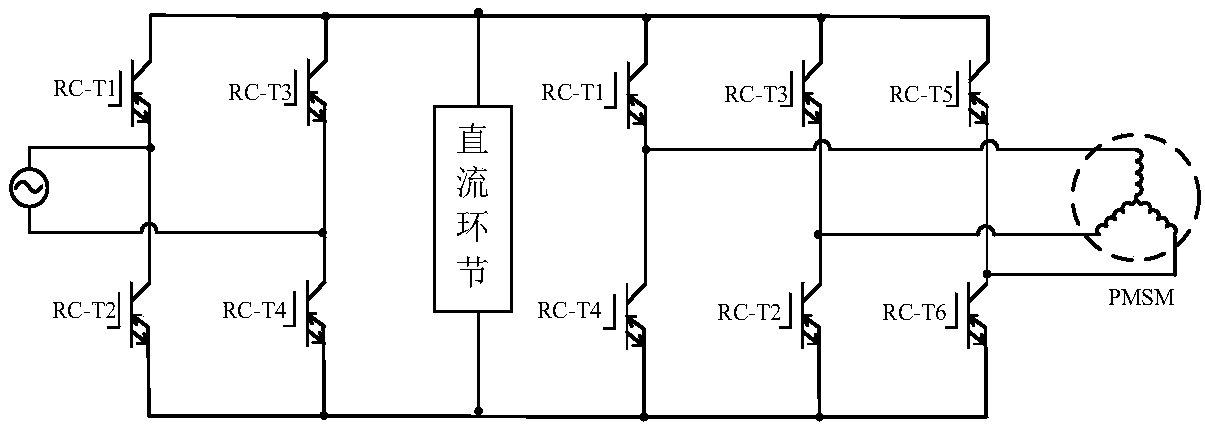

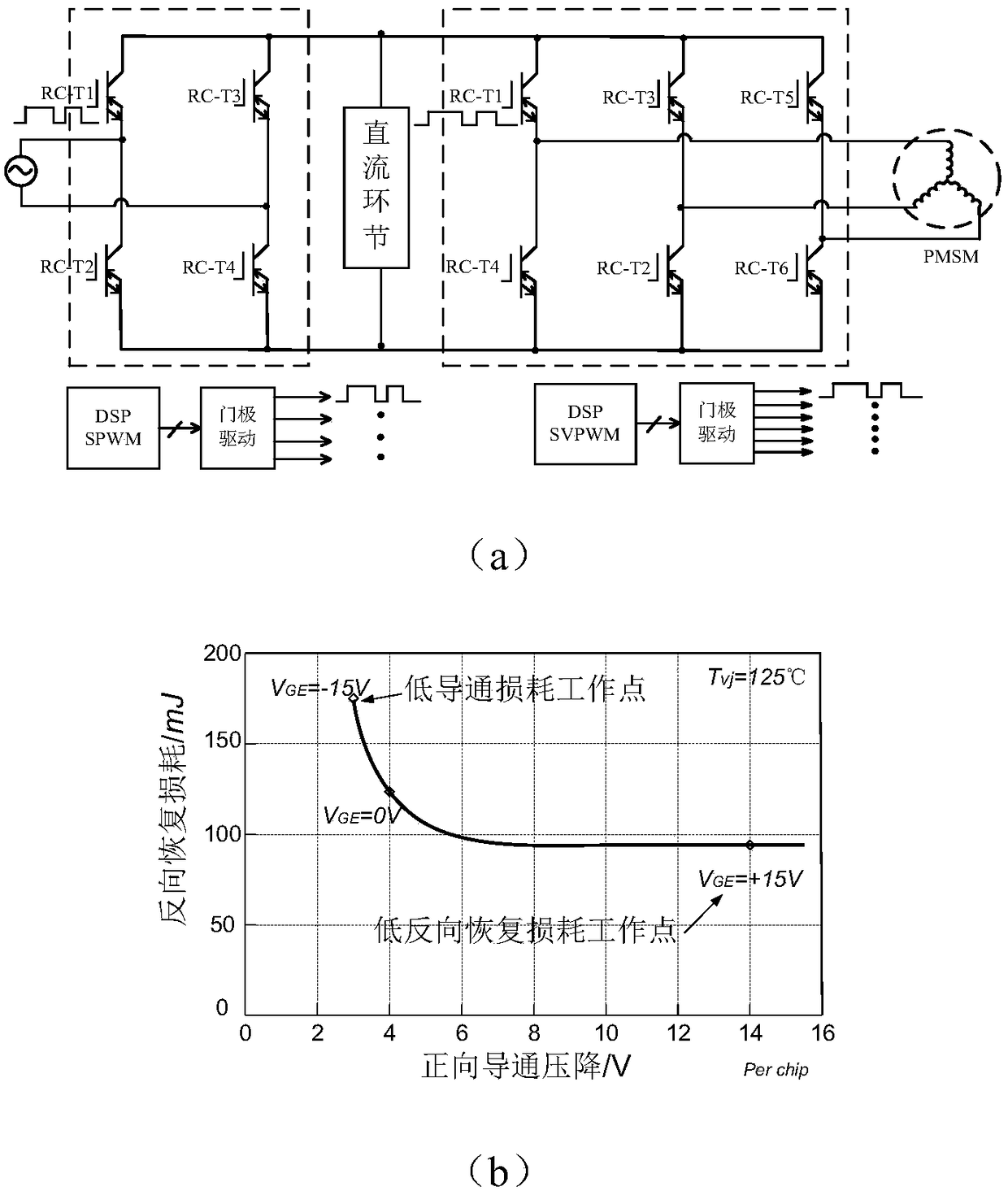

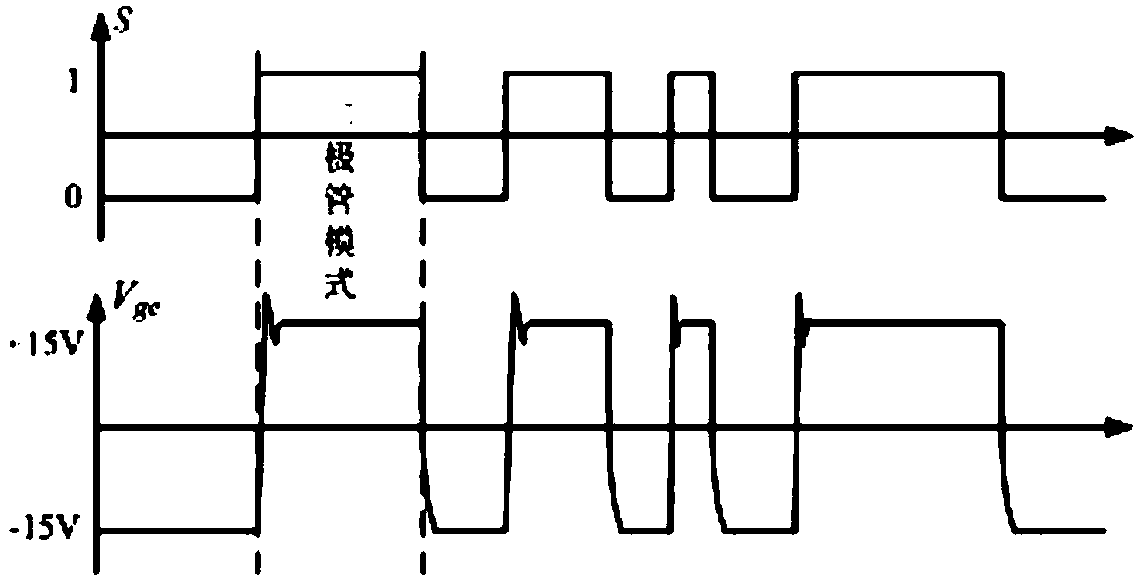

[0047] Such as Figure 1-7 As shown, the reverse conduction type IGBT gate pre-desaturation drive circuit based on current threshold judgment in the present invention includes: reverse conduction type IGBT mode detection circuit, current detection circuit, external MOSFET drive level adjustment circuit, three-state Gate 3 and IGBT drive push-pull circuit 4;

[0048] The reverse conduction type IGBT mode detection circuit includes a voltage comparator 1, a NOT gate 7, a voltage source 8 and a collector collecting voltage module 9, wherein one end of the collector collection voltage module 9 is connected to the collector of the reverse conduction type IGBT C connection, the two input terminals of the voltage comparator 1 are respectively connected with the other end of the voltage source 8 and the collector voltage acquisition module 9, and the output terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com