Aerated grit sand setting deslagging basin and sewage treatment system thereof

A sewage treatment system and aeration sand settling technology, which is applied in the direction of sedimentation tank, sedimentation tank, sedimentation separation, etc., can solve the problems such as wear of the sand suction end of the truss truck, inability to stop, tedious pump adjustment work, etc., to avoid corrosion and wear, Improve the service life and improve the effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

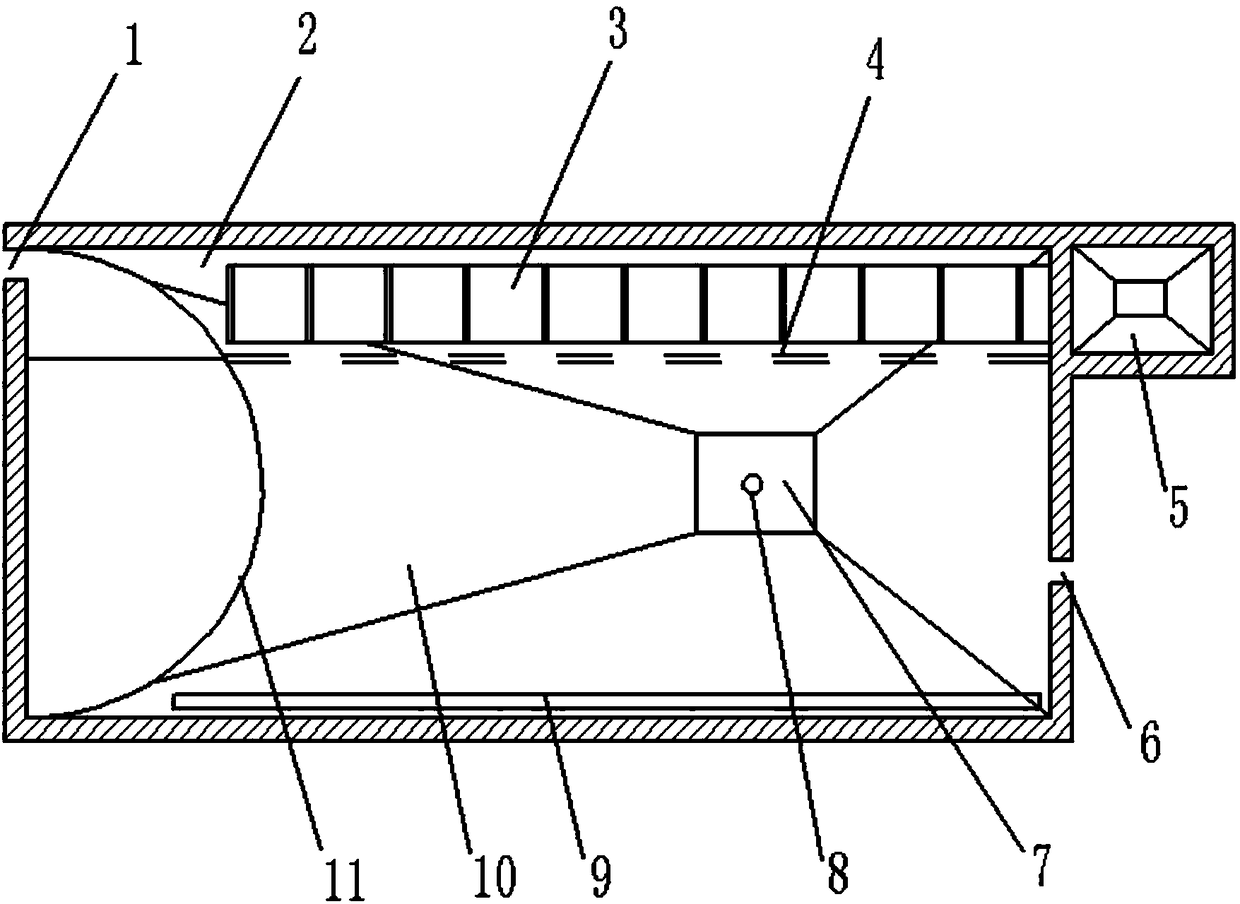

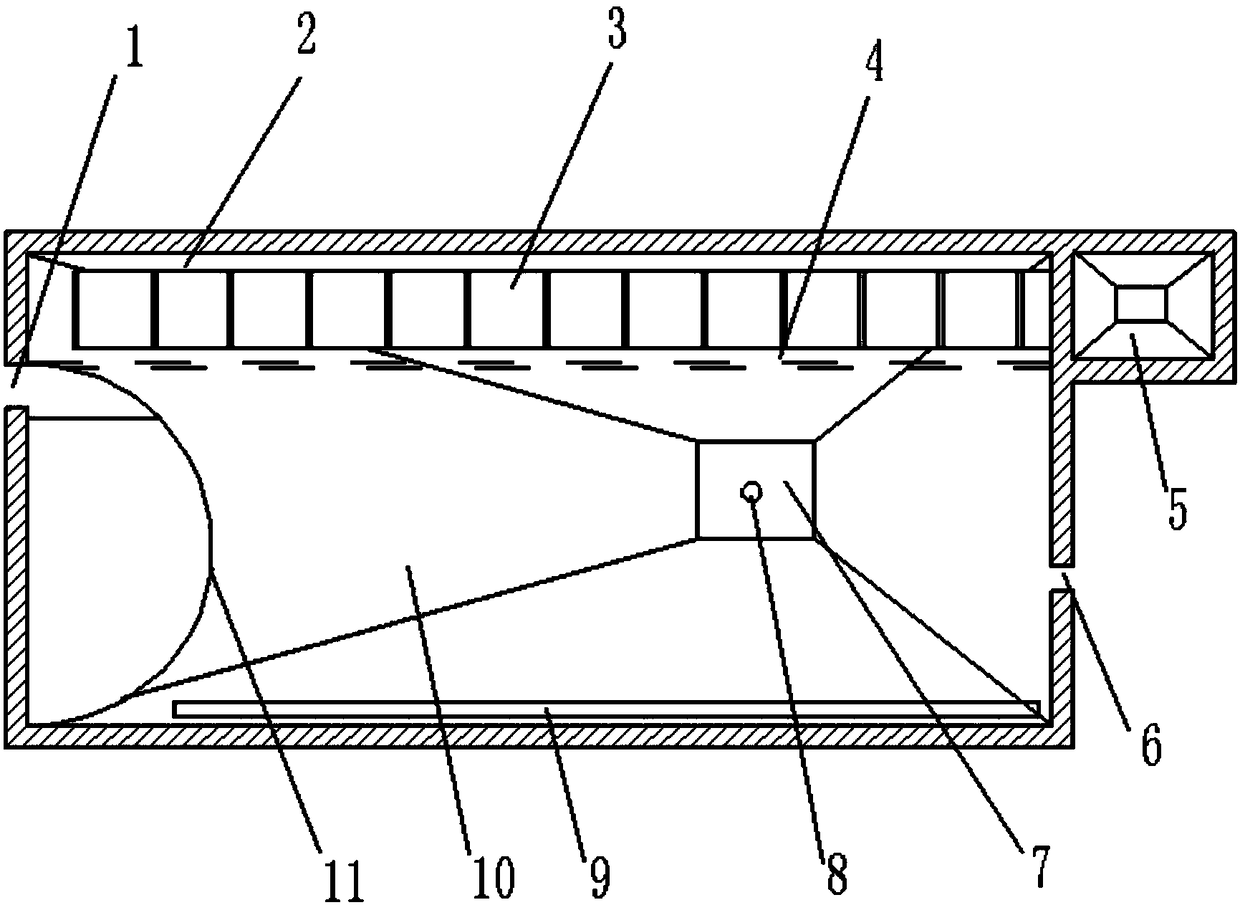

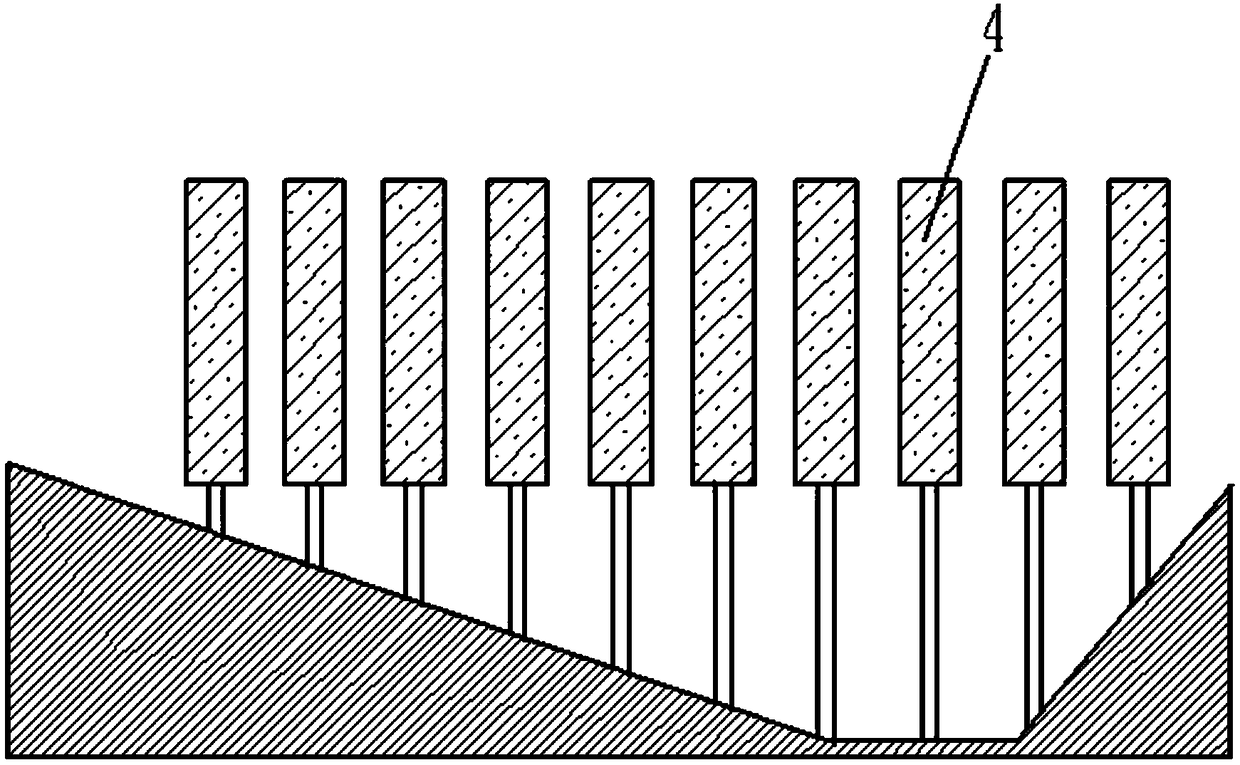

[0074] Such as Figure 1a and Figure 2-5 As shown, an aeration and deslagging tank includes a tank body, an aeration pipe 9, a first slag collecting structure 5 and a slag scraping mechanism 3, the tank body includes a water inlet 1 and a first water outlet 6, and the tank The bottom surface of the body includes an arc-shaped surface 13, a slope 14, and a sand collection area 7 from the water inlet to the water outlet. Sand suction pipe 8 is arranged, and sand suction pipe is connected with sand suction pump 31; The first water outlet is submerged weir.

[0075] It also includes a water distributor, the water distributor is combined with the arc surface to realize water distribution; the water distributor spans the width direction of the aeration sand settling and slag removal tank, and the water distributor consists of a water distribution plate 11 whose top is not lower than the water surface Composition, the water distribution plate includes a vertically arranged arc pane...

Embodiment 2

[0081] Such as Figure 1b and Figure 2-5 As shown, a kind of aerated sand sedimentation and slag removal tank includes a tank body, an aeration pipe, a first slag collecting structure and a slag scraping mechanism. The tank body includes a water inlet and a first water outlet. From the water end to the water outlet, it includes an arc surface, a slope and a sand collection area in turn. The sand collection area is surrounded by slopes that allow sand particles to gather in the sand collection area. The sand collection area is equipped with sand suction pipes. It is connected with the sand suction pump; the first water outlet is the overflow weir.

[0082] It also includes a water distributor, which is combined with the curved surface to realize water distribution; the water distributor spans the width direction of the aeration, sand, and slag removal tank, and the water distributor is composed of a water distribution board whose top is not lower than the water surface , the w...

Embodiment 3

[0088] Such as Figure 6-8 As shown, a kind of aerated sand sedimentation and slag removal tank includes a tank body, an aeration pipe, a first slag collecting structure and a slag scraping mechanism. The tank body includes a water inlet and a first water outlet. From the water end to the water outlet, it includes an arc surface, a slope and a sand collection area in turn. The sand collection area is surrounded by slopes that allow sand particles to gather in the sand collection area. The sand collection area is equipped with sand suction pipes. Connected with the sand suction pump; the first water outlet can be an overflow weir.

[0089] It also includes a water distributor, which is combined with the curved surface to realize water distribution; the water distributor spans the width direction of the aeration, sand, and slag removal tank, and the water distributor is composed of a water distribution board whose top is not lower than the water surface , the water distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com