Self-repairing self-lubricating material and preparation method thereof

A self-healing, solid self-lubricating technology, used in the field of self-healing self-lubricating materials, can solve the problems of irreversibility, poor interface adhesion, limited modification effect, etc., to achieve self-healing and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

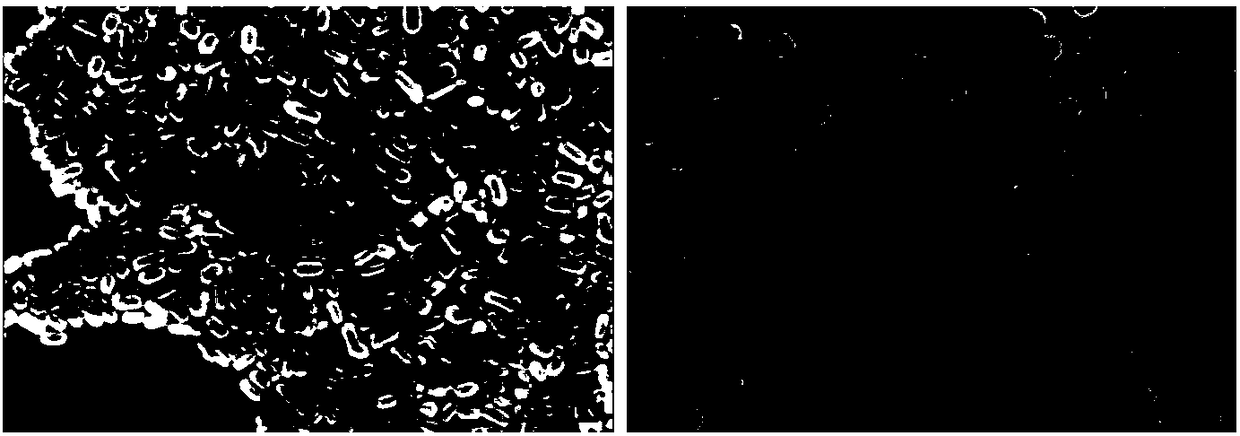

[0051] (1) Preparation of PTFE core-shell particles

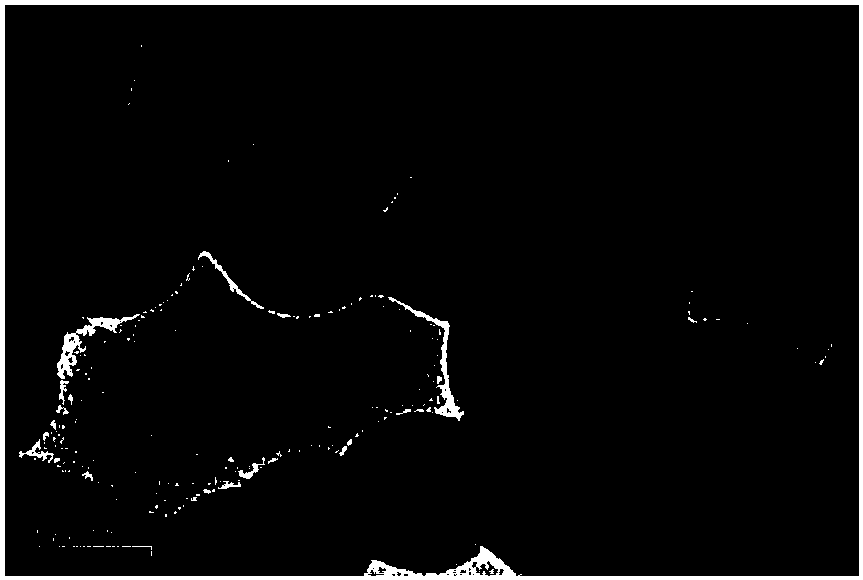

[0052] Add 70 ml of PTFE dispersion into a four-necked flask containing 500 ml of deionized water under stirring at 300 rpm, add 70 ml of methyl methacrylate (0.654 mol) after heating to 75 °C. After being stable for 30 min, potassium persulfate aqueous solution (10 mL, 0.74 mmol) was added, reacted under nitrogen atmosphere for 20 h, and the product was collected by repeated centrifugation, and dried at 85°C for 5 h to obtain polymethyl methacrylate-coated PTFE core-shell nanoparticles. SEM was used to characterize the samples before and after PTFE core-shell modification, the results are as follows figure 1 shown. Depend on figure 1 It can be seen that the pure PTFE has an ellipsoidal structure before modification, and a spherical structure after modification. In order to further analyze the structure of the modified product, we used transmission electron microscopy to characterize the modified sample, the results are ...

Embodiment 2

[0060] (1) Preparation of PTFE core-shell particles

[0061] Add 70 ml of PTFE dispersion into a four-necked flask containing 400 ml of deionized water under stirring at 400 rpm, add 35 ml of methyl methacrylate after heating to 70 °C. After being stable for 30 minutes, aqueous potassium persulfate solution (10 mL, 0.37 mmol) was added, reacted for 24 hours under nitrogen atmosphere, and the product was collected by repeated centrifugation, and dried at 80°C for 8 hours to obtain polymethyl methacrylate-coated PTFE core-shell particles.

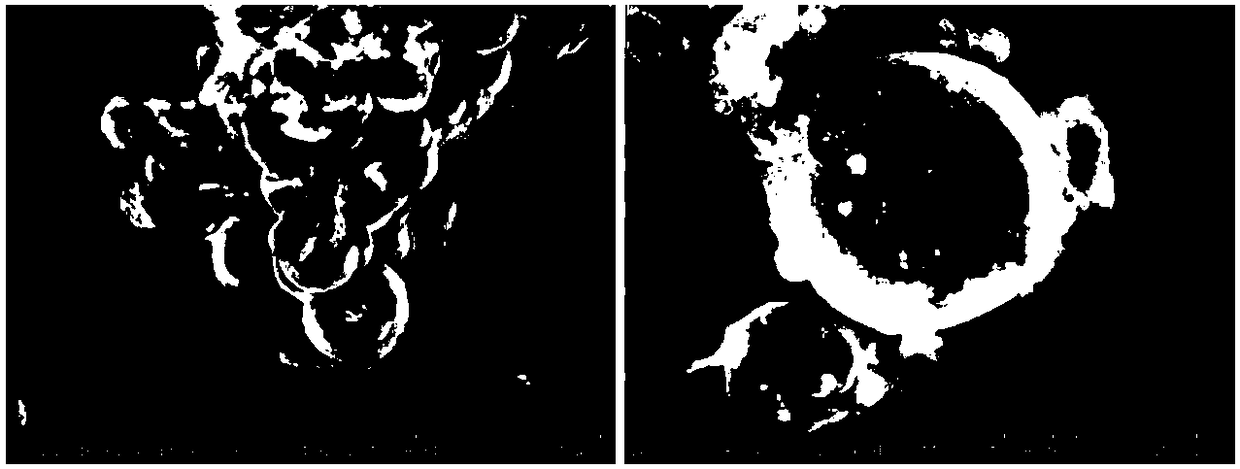

[0062] (2) Preparation of microcapsules

[0063] 10 ml of graphene oxide dispersion was mixed with 0.8 g of linseed oil, mixed under high shear at 900 rpm for 15 minutes to prepare Pickering emulsion, and dried at room temperature for 10 h to obtain microcapsules.

[0064] (3) Preparation of self-healing self-lubricating composite film

[0065] A certain amount of PTFE core-shell particles and microcapsules are mixed in a solvent, and a com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com