A kind of method for making nano silver wire transparent conductive film have the function of eliminating shadow

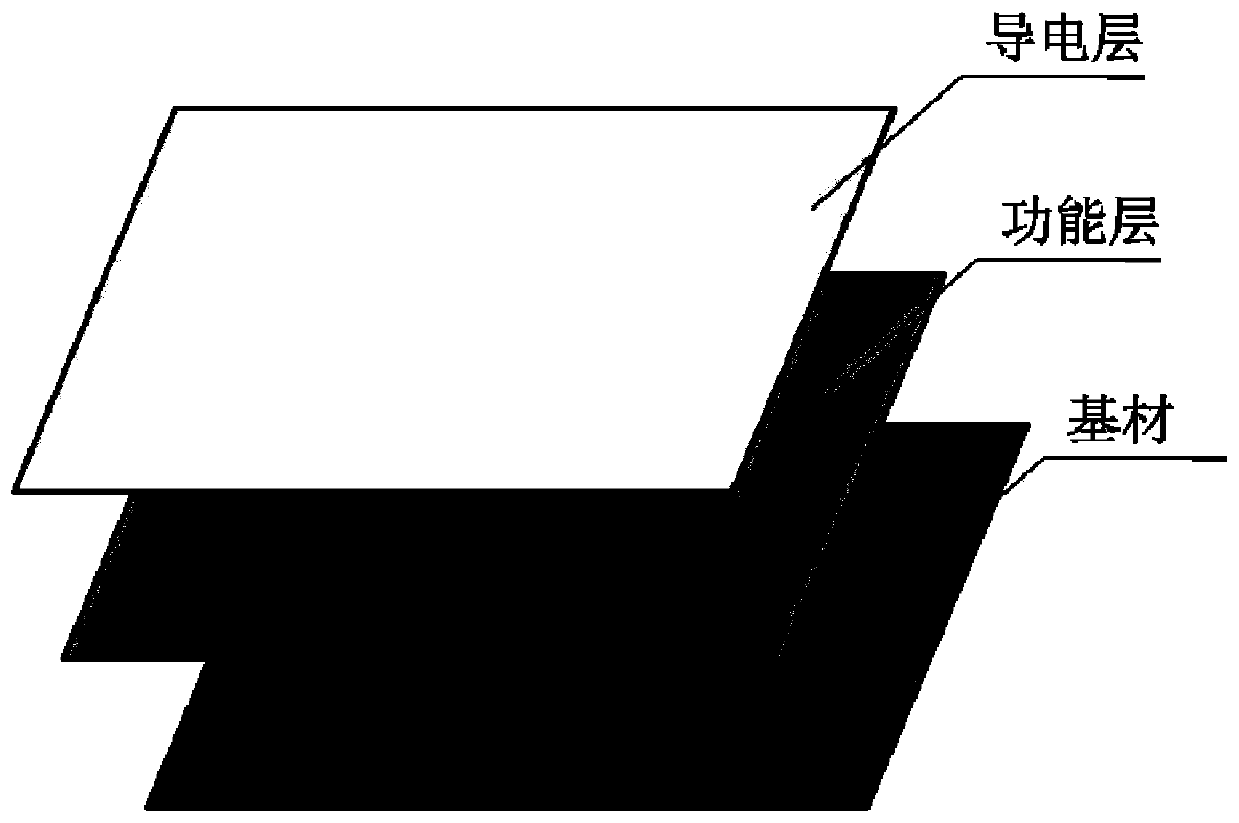

A transparent conductive film and nano-silver wire technology, applied to conductive layers, circuits, electrical components and other directions on insulating carriers, can solve the problem of inability to completely eliminate etching marks, difficult to control etching yield, and failure to achieve the purpose of erasing and other problems, to achieve the effect of high reliability, improved weather resistance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

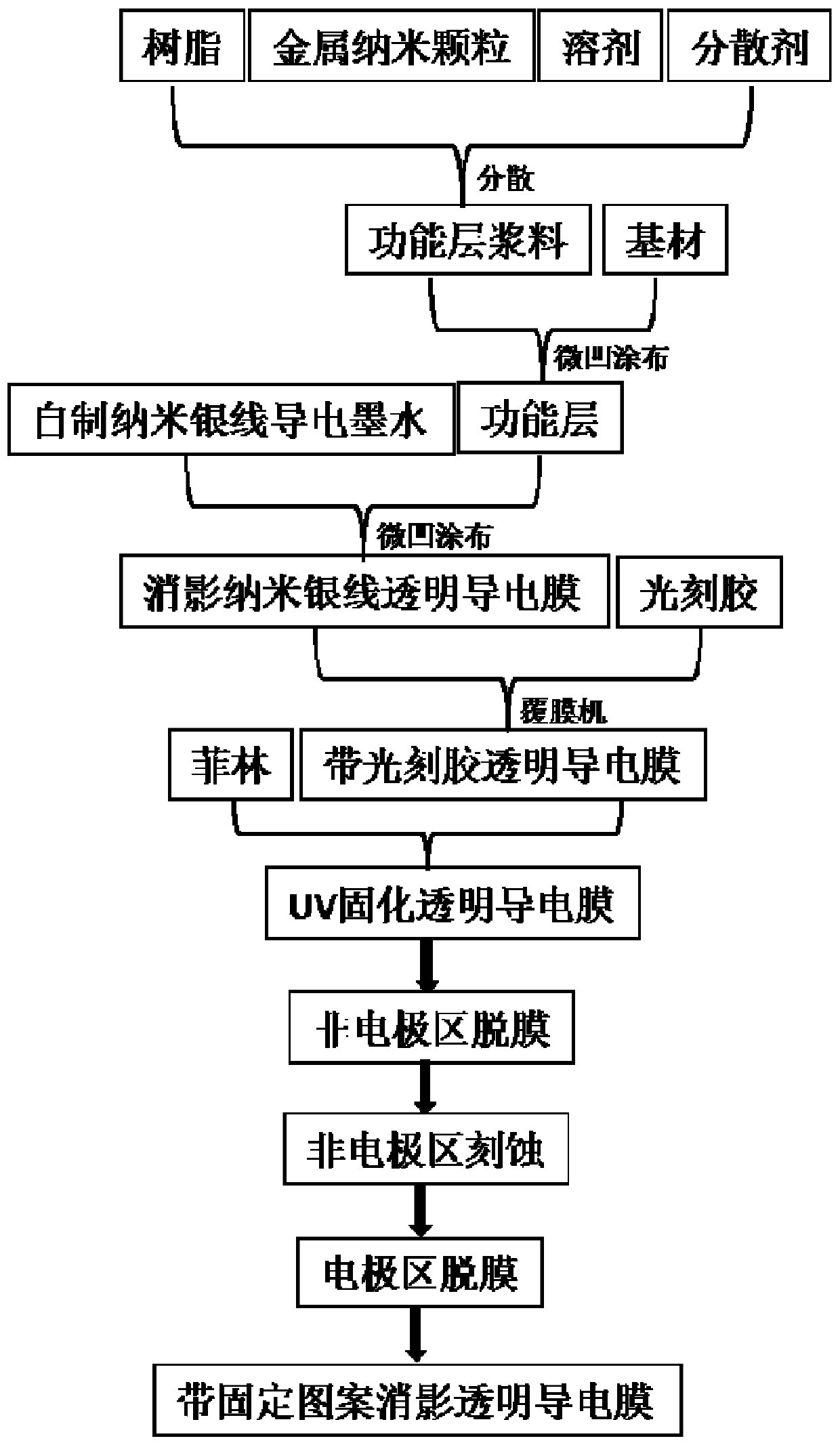

[0047] (1) Functional layer preparation: 0.4kg polyether polyol HSH360, 0.3kg curing agent Bayhydur 305, 0.4kg water-based nano-zirconia VK-R30W (Xuancheng Jingrui new material, particle size 30nm), 8.8kg water, 0.1kg ten two Sodium alkylbenzene sulfonate is added to the dispersion cylinder in turn, and dispersed for 2 minutes using a planetary gravity disperser to obtain a functional layer slurry; Dry at 100°C for 15 minutes to obtain a functional layer;

[0048] (2) Conductive layer preparation: Nano silver wire (selected from Hefei Microcrystalline Material Technology Co., Ltd., model WJAG1, available in the market), Bayhydrol xp 2470, sodium polyacrylate, water in a mass ratio of 1:2:2:995 The conductive ink is prepared by mixing uniformly, and the ink is coated on the surface of the functional layer by a dimple coating process, and dried in a tunnel oven at 90°C for 20s to form a transparent conductive layer of silver nanowires, that is, to obtain a transparent conducti...

Embodiment 2

[0053] (1) Functional layer preparation: 0.4kg polyether polyol HSH360, 0.3kg curing agent Bayhydur 305, 0.4kg water-based nano-cuprous oxide DK407-1 (Beijing Deke Island gold, particle size 40nm), 8.8kg water, 0.1 kg of sodium dodecylbenzene sulfonate was added to the dispersion tank in turn, and dispersed for 2 minutes using a planetary gravity disperser to obtain a functional layer slurry; The functional layer was obtained by drying in a tunnel furnace at 100°C for 15 minutes;

[0054] (2) Conductive layer preparation: nano-silver wire (selected from Hefei Microcrystalline Material Technology Co., Ltd., model WJAG1, available in the market), Bayhydrol xp 2470, sodium polyacrylate, and water are mixed uniformly in the same ratio as in Example 1 The conductive ink is prepared, and the ink is coated on the surface of the functional layer by a dimple coating process, and dried in a tunnel oven at 90° C. for 20 s to form a transparent conductive layer of silver nanowires, that i...

Embodiment 3

[0057] (1) Functional layer preparation: 0.4kg polyether polyol HSH360, 0.3kg curing agent Bayhydur 305, 0.2kg water-based nano-alumina VK-L20W (Xuancheng Jingrui new material, particle size 20nm), 0.2kg water-based nano-alumina Zirconia VK-R30W (Xuancheng Jingrui new material, particle size 30nm), 8.8kg water, 0.1kg sodium dodecylbenzene sulfonate were added to the dispersion tank in turn, and dispersed for 2 minutes using a planetary gravity disperser to obtain a functional layer Slurry; then use the dimple coating equipment to uniformly coat the slurry on the PET substrate, and dry it in a tunnel oven at 100°C for 15 minutes to obtain a functional layer;

[0058] (2) Conductive layer preparation: nano-silver wire (selected from Hefei Microcrystalline Material Technology Co., Ltd., model WJAG1, available in the market), Bayhydrol xp 2470, sodium polyacrylate, and water are mixed uniformly in the same ratio as in Example 1 The conductive ink is prepared, and the ink is coated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com