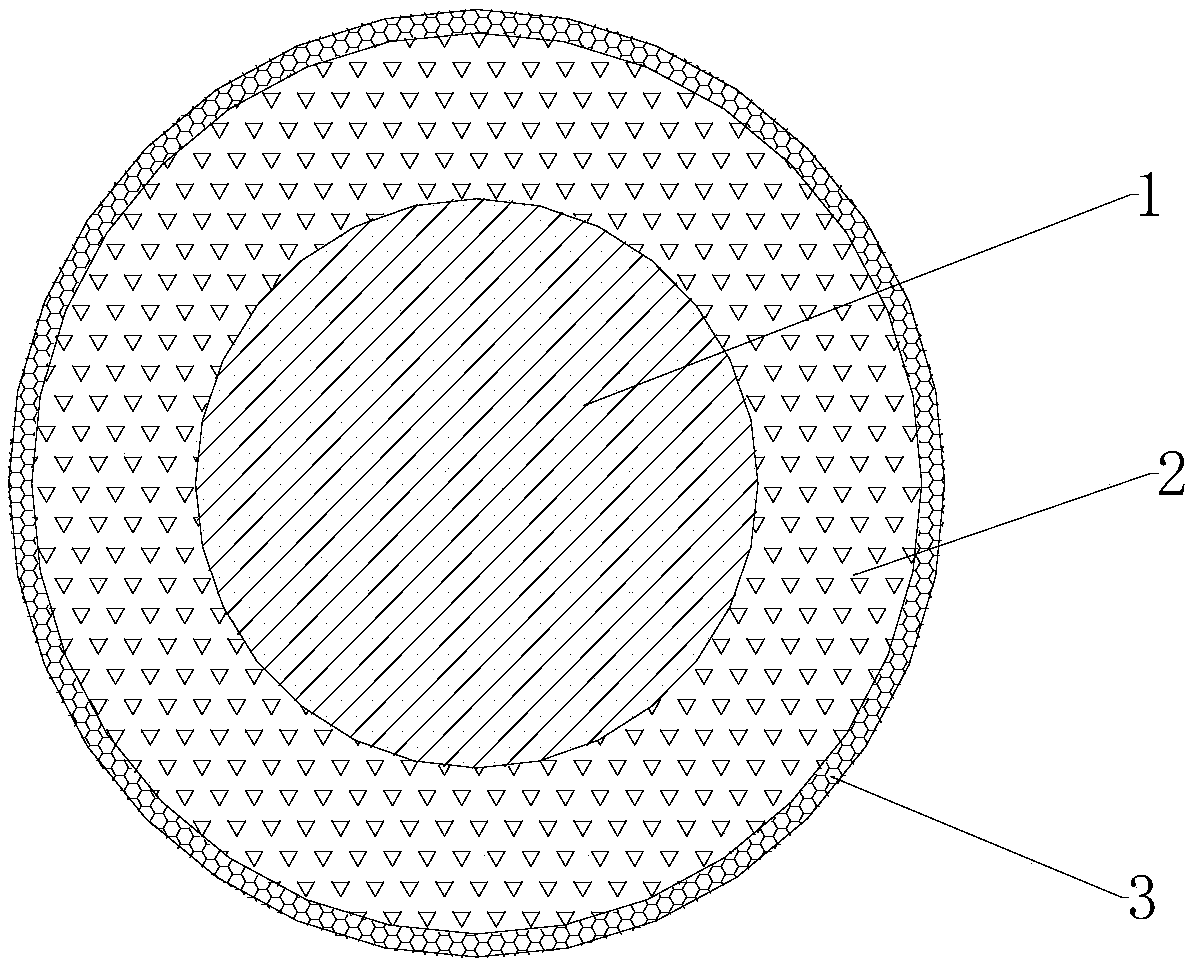

Apple-shaped embedded silicon carbon negative electrode material and preparation method thereof

A negative electrode material, silicon carbon material technology, applied in the field of apple-shaped embedded silicon carbon negative electrode material and its preparation, can solve the problems of affecting application, material pulverization and falling off, cycle performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing an apple-shaped embedded silicon-carbon negative electrode material, comprising the steps of:

[0026] 1) Add natural graphite, absolute ethanol and polyethylene glycol accounting for 1% of the graphite mass into a sand mill for ball milling until the particle size is D 50 =1 μm, to obtain slurry I;

[0027] 2) Slurry I is spray-dried in a nitrogen atmosphere with a pressure spray drying unit. During spray drying, the inlet temperature is 210°C and the pressure is 0.7Mpa to obtain material I. The shape of material I is a cylinder with rounded edges shape;

[0028] 3) The material I was roasted once at 450°C in a nitrogen atmosphere for 12 hours to obtain the material II;

[0029] 4) Combine material II, absolute ethanol, polyethylene glycol and particle size D 50 The silicon powder of =90nm is added into the stirring ball mill for stirring, the quality of the silicon powder is 5% of the quality of the material II, the quality of polyethylene gl...

Embodiment 2

[0034] A method for preparing an apple-shaped embedded silicon-carbon negative electrode material, comprising the steps of:

[0035] 1) Add artificial graphite, absolute ethanol and polyethylene glycol accounting for 1% of the graphite mass into a sand mill for ball milling until the particle size is D 50 =1 μm, to obtain slurry I;

[0036] 2) Slurry I is spray-dried in a nitrogen atmosphere with a pressure spray drying unit. During spray drying, the inlet temperature is 160°C and the pressure is 0.4Mpa to obtain material I. The shape of material I is a cylinder with rounded edges shape;

[0037] 3) The material I was roasted once at 700° C. in a nitrogen atmosphere, and the roasting time was 6 hours to obtain the material II;

[0038] 4) Combine material II, absolute ethanol, polyethylene glycol and particle size D 50 The silicon powder of =90nm is added into the stirring ball mill for stirring, the quality of the silicon powder is 5% of the quality of the material II, the...

Embodiment 3

[0043] A method for preparing an apple-shaped embedded silicon-carbon negative electrode material, comprising the steps of:

[0044] 1) Add artificial graphite, absolute ethanol and polyvinyl alcohol accounting for 3% of the graphite mass into a sand mill for ball milling until the particle size after ball milling is D 50 =0.8 μm, to obtain slurry I;

[0045] 2) Slurry I is spray-dried in an argon atmosphere with a pressure spray drying unit. During spray drying, the inlet temperature is 200°C and the pressure is 0.7Mpa to obtain material I. The shape of material I is a circle with rounded edges Cylindrical;

[0046] 3) The material I was roasted once at 700°C in an argon atmosphere for 12 hours to obtain material II;

[0047] 4) Combine material II, absolute ethanol, polyvinyl alcohol and particle size D 50 =90nm silicon powder is added into the stirring ball mill for stirring, the quality of the silicon powder is 10% of the quality of the material II, the quality of polyv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com