Camellia chrysantha leaf health-care tea capable of reducing blood sugar as well as preparation method and application of camellia chrysantha leaf health-care tea

A tea leaf and blood sugar-lowering technology, applied in golden camellia tea leaf blood-sugar-lowering health tea and its preparation and application fields, can solve the problems of heavy economic burden for diabetic patients, high price of insulin injection, loss of islet function, etc., and achieve no toxic and side effects , large yield, simple planting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

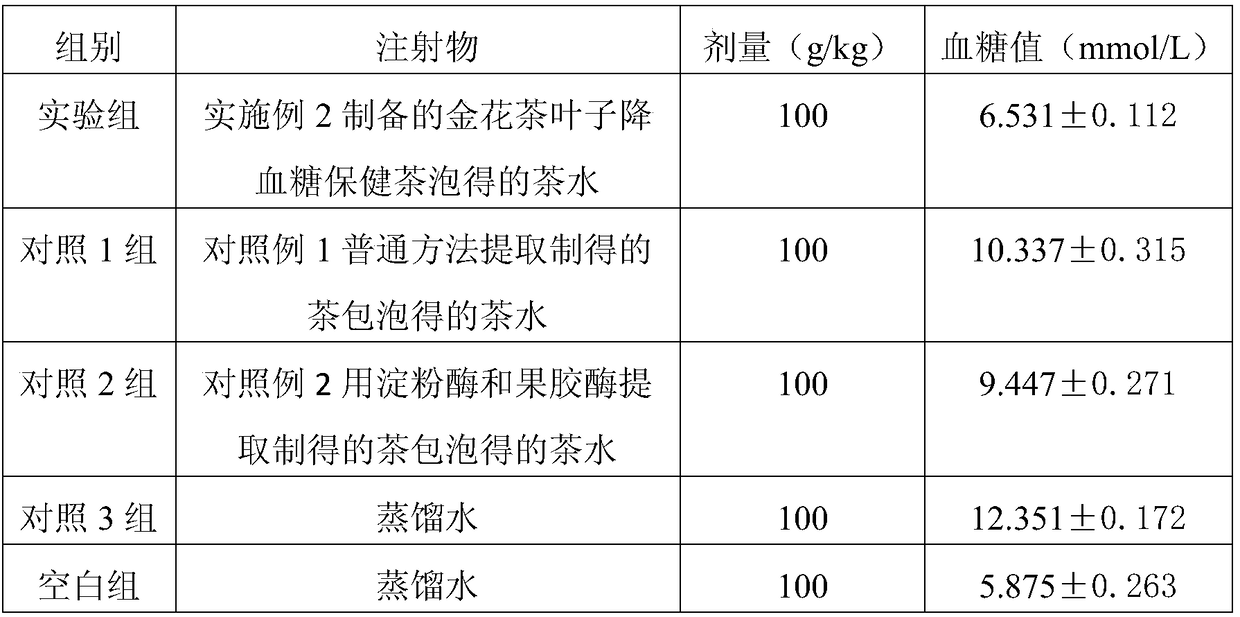

Problems solved by technology

Method used

Image

Examples

Embodiment 1

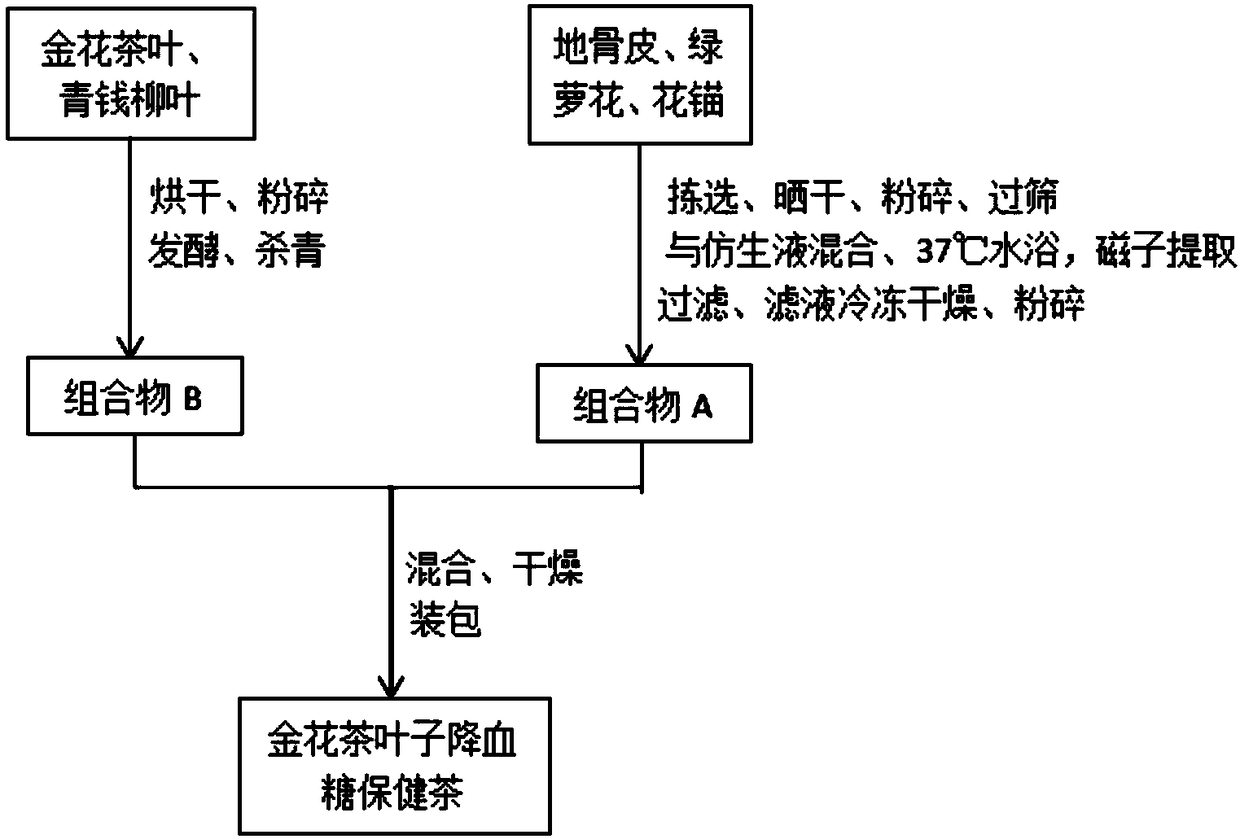

[0027] The preparation of embodiment 1 golden camellia leaves hypoglycemic health care tea

[0028] Composition of raw materials: 20 parts of golden camellia leaves, 15 parts of Cyclocarya paliurus, 15 parts of Digupi, 10 parts of pothos, 7 parts of flower anchor;

[0029] Prepare as follows:

[0030] (1) Sorting Digupi, Podocarpus, and Flower Anchor, drying in the sun, crushing, passing through a 60-mesh sieve, and mixing the obtained powder with the bionic extract at a weight ratio of 1:10, heating in a water bath at 37°C, and plastic film Seal, extract with magneton for 100 minutes, filter, collect the filtrate, freeze-dry, and pulverize to obtain composition A powder with a yield of 67%;

[0031] (2) Wash Camellia japonica leaves and Cyclocarya paliurus leaves, dry them in vacuum at a constant temperature of 30°C, pulverize them, put them into a sealed container for fermentation at 40°C for 5 days, and fry them at 200-300°C for 5 minutes to obtain composition B powder. 7...

Embodiment 2

[0034] The preparation of embodiment 2 golden camellia leaves hypoglycemic health tea

[0035] Composition of raw materials: 25 parts of Camellia japonica leaves, 17 parts of Cyclocarya paliurus, 17 parts of Digupi, 12 parts of pothos, 10 parts of flower anchor;

[0036] Prepare as follows:

[0037] (1) Select Digupi, Podocarpus, and Flower Anchor, dry, crush, and pass through an 80-mesh sieve. The obtained powder is mixed with the bionic extract at a weight ratio of 1:30, heated in a water bath at 37°C, and plastic film Seal, extract with magneton for 120 minutes, filter, collect the filtrate, freeze-dry, and pulverize to obtain composition A powder with a yield of 89%;

[0038] (2) Wash Camellia japonica leaves and Cyclocarya paliurus leaves, vacuum-dry them at a constant temperature of 35°C, pulverize them, put them into a sealed container for fermentation at 50°C for 7 days, and fry them at 270°C for 8 minutes to obtain composition B powder with a yield of 92%. ;

[003...

Embodiment 3

[0041] The preparation of embodiment 3 golden camellia leaves hypoglycemic health tea

[0042] Composition of raw materials: 30 parts of golden camellia tea leaves, 20 parts of Cyclocarya paliurus, 20 parts of Digupi, 15 parts of pothos, 12 parts of flower anchor;

[0043] Follow the steps below:

[0044] (1) Sorting Digupi, Podocarpus, and Flower Anchor, drying, crushing, passing through a 120-mesh sieve, and mixing the obtained powder with the bionic extract at a weight ratio of 1:50, heating in a water bath at 37°C, and plastic film Seal, extract with magneton for 180 minutes, filter, collect the filtrate, freeze-dry, and pulverize to obtain composition A powder with a yield of 82%;

[0045] (2) Wash Camellia japonica leaves and Cyclocarya paliurus leaves, dry them in vacuum at a constant temperature of 40°C, pulverize them, put them into a sealed container for fermentation at 60°C for 10 days, and then fry them at 300°C for 10 minutes to obtain composition B powder with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com